Multi-arc ion plating superlattice nanometer composite coating and preparation method of multi-arc ion plating superlattice nanometer composite coating

A nano-composite coating, multi-arc ion plating technology, applied in ion implantation plating, coating, metal material coating technology and other directions, can solve the problems of low film deposition efficiency, reduced mechanical properties, difficult to large-scale industrial production and other problems , to achieve the effect of improving the bonding strength, compensating for the decrease in hardness, high hardness and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

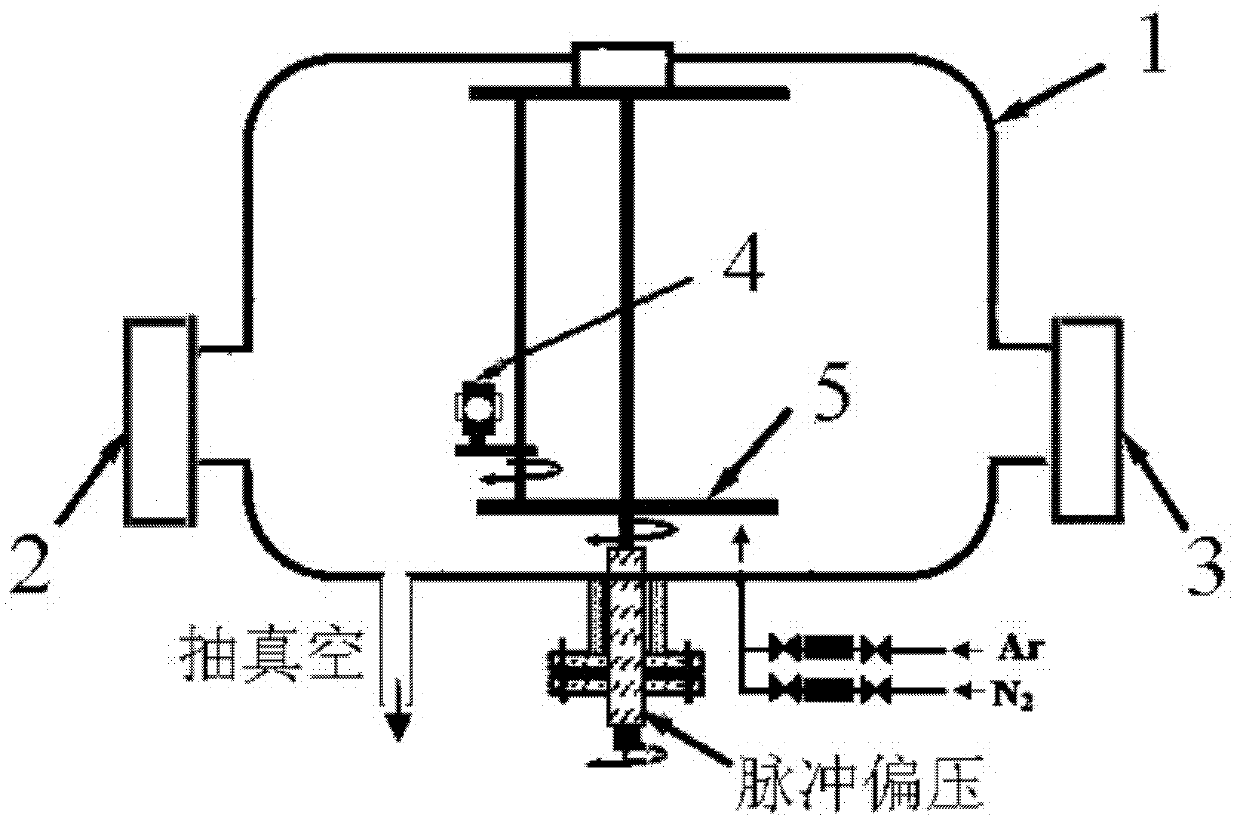

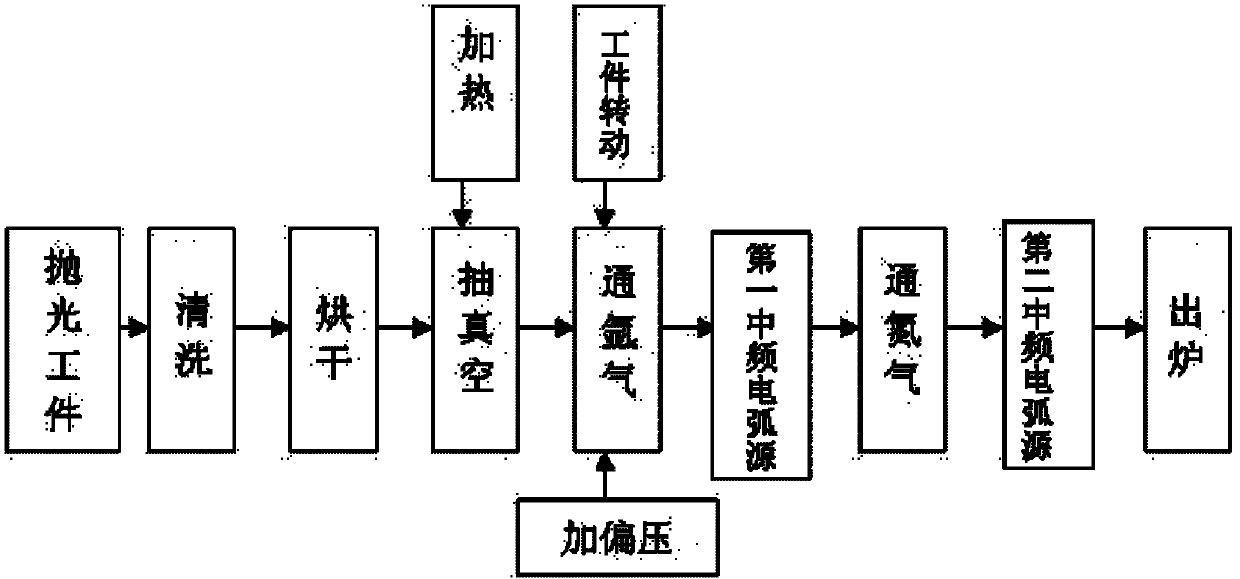

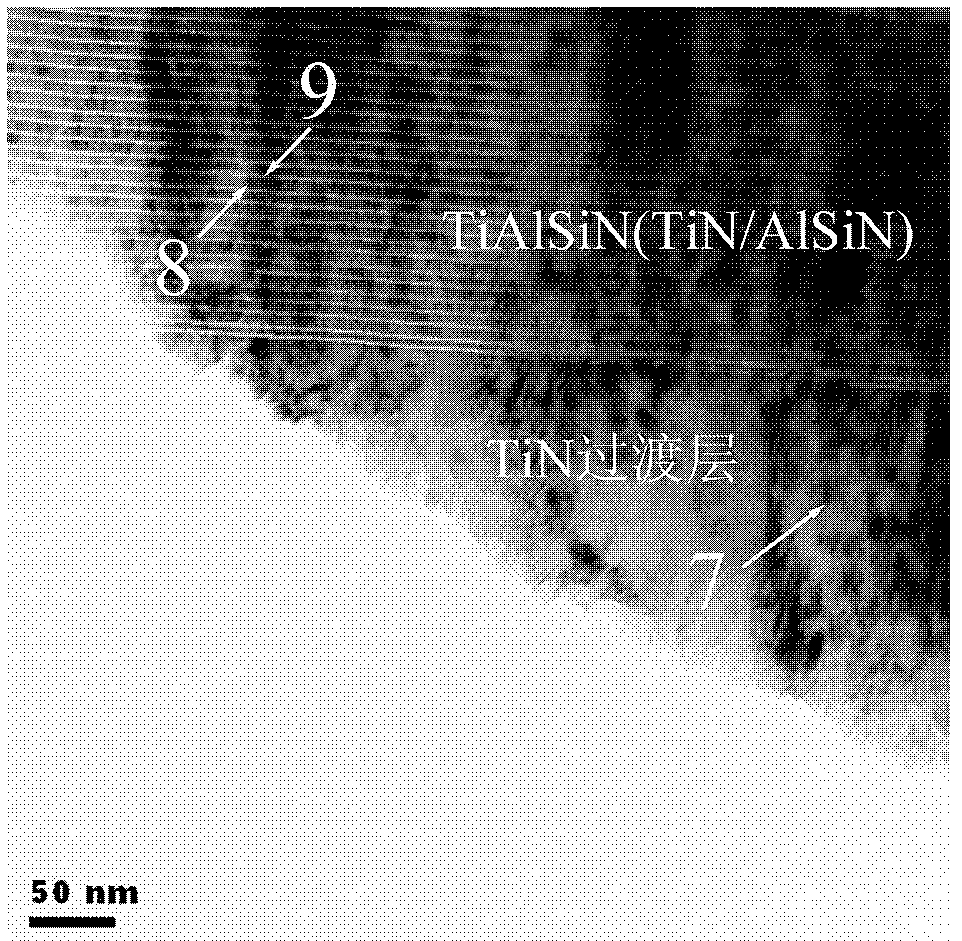

[0042] Such as figure 1 with figure 2 As shown, a kind of preparation method of multi-arc ion plating superlattice nanocomposite coating of the present embodiment comprises the following steps:

[0043] (1) The first intermediate frequency arc source 2 and the second intermediate frequency arc source 3 are respectively arranged on both sides of the vacuum chamber 1, N 2and Ar gas into the vacuum chamber 1, the target of the first intermediate frequency arc source 2 is made of Ti simple substance with a purity of 99.9%; the target of the second intermediate frequency arc source 3 is made of AlSi powder metallurgy, Al and Si The atomic percentage is 88:12, and the purity of the AlSi target is 99.9%;

[0044] (2) The workpiece after polishing is cleaned successively with acetone and alcohol ultrasonic waves for 15 minutes, and after drying, it is clamped on the fixture 4. The fixture 4 is arranged on the turntable 5, and the turntable 5 is located in the vacuum chamber 1. Vac...

Embodiment 2

[0056] The preparation method of the superlattice nanocomposite coating of the present embodiment, comprises the following steps:

[0057] (1) The first intermediate frequency arc source 2 and the second intermediate frequency arc source 3 are respectively arranged on both sides of the vacuum chamber 1, N 2 and Ar gas into the vacuum chamber 1, the target of the first intermediate frequency arc source 2 is made of Ti simple substance with a purity of 99.9%; the target of the second intermediate frequency arc source 3 is made of AlSi powder metallurgy, Al and Si The atomic percentage is 88:12, and the purity of the AlSi target is 99.9%;

[0058] (2) The workpiece after polishing is cleaned successively with acetone and alcohol ultrasonic waves for 15 minutes, and after drying, it is clamped on the fixture 4. The fixture 4 is arranged on the turntable 5, and the turntable 5 is located in the vacuum chamber 1. Vacuum to a vacuum of 7×10 -3 Pa, the heating temperature is 300°C, ...

Embodiment 3

[0066] The preparation method of the superlattice nanocomposite coating of the present embodiment, comprises the following steps:

[0067] (1) The first intermediate frequency arc source 2 and the second intermediate frequency arc source 3 are respectively arranged on both sides of the vacuum chamber 1, N 2 and Ar gas into the vacuum chamber 1, the target of the first intermediate frequency arc source 2 is made of Ti simple substance with a purity of 99.9%; the target of the second intermediate frequency arc source 3 is made of AlSi powder metallurgy, Al and Si The atomic percentage is 88:12, and the purity of the AlSi target is 99.9%;

[0068] (2) The workpiece after polishing is cleaned successively with acetone and alcohol ultrasonic waves for 15 minutes, and after drying, it is clamped on the fixture 4. The fixture 4 is arranged on the turntable 5, and the turntable 5 is located in the vacuum chamber 1. Vacuum to a vacuum of 7×10 -3 Pa, the heating temperature is 500°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com