Method for separating capsaicinoids monomers from capsaicinoids compounds

A technology of capsaicin and compounds, which is applied in the field of separation of capsaicin monomers and capsaicin monomers, can solve the problems of large consumption of solvents and fillers, unsuitability for large-scale production, unfavorable environmental friendliness, etc., and achieves simple operation and high efficiency. The effect of choosing separation ability and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

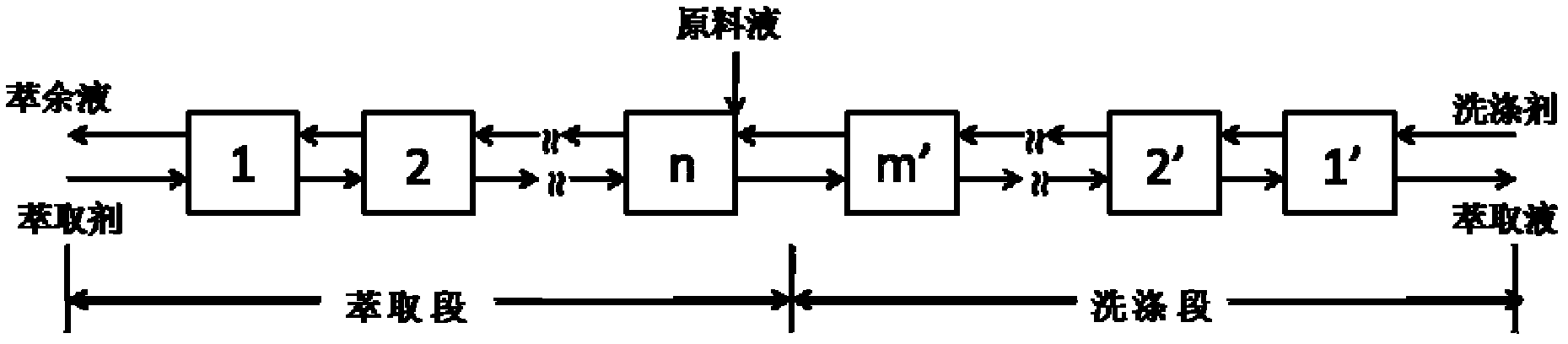

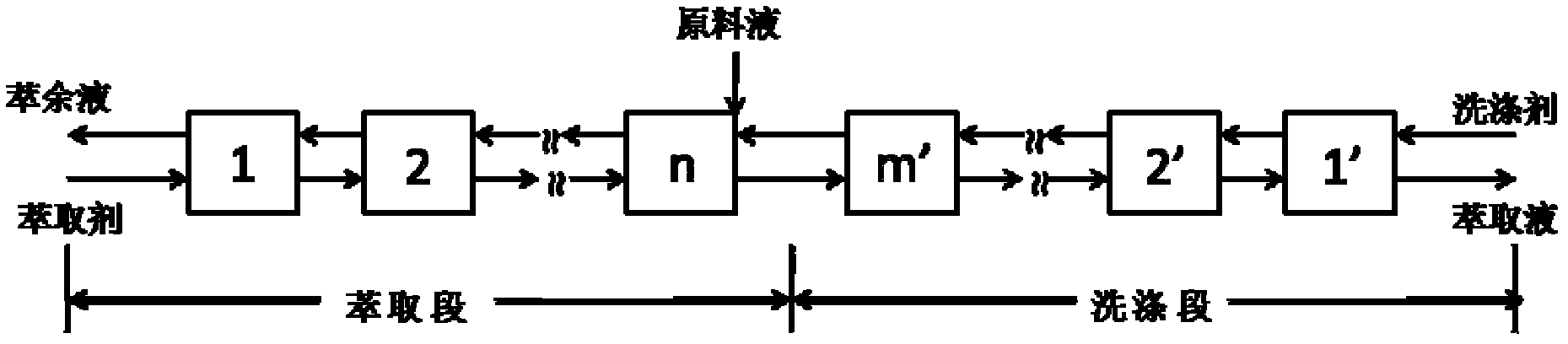

[0046] Commercially available capsaicin compounds (wherein the total weight percent of capsaicin and dihydrocapsaicin are 92%) and sulfolane aqueous solution (sulfolane molar fraction is 20%) are made into a capsaicin compound concentration of 3 grams per liter of stock solution , with dodecane as extractant, with sulfolane aqueous solution (sulfolane mole fraction is 20%) as detergent, the flow ratio between raw material liquid, extractant, detergent three is 0.3: 20: 1, at 30 ℃ figure 1 Fractional extraction is carried out in the fractionation extraction device shown (there are 15 stages in the extraction section and 6 stages in the washing section), the raffinate is collected, water and organic solvents are removed by vacuum concentration, washed with water and dried to obtain the final product. Through HPLC analysis, the absolute purity of capsaicin in the final product is 98.9%, the relative content of capsaicin:dihydrocapsaicin is 99.1:0.9, and the yield is 98.7%.

Embodiment 2

[0048] Commercially available capsaicin compound (wherein the total weight percent of capsaicin and dihydrocapsaicin is 92%) and aqueous methanol (methanol molar fraction is 95%) is made into the stock solution that capsaicin compound concentration is 50 g / liter , with 1-octene as extractant, methanol aqueous solution (methanol mole fraction is 95%) as detergent, the flow ratio between raw material liquid, extractant and detergent is 6:50:1, at 55°C exist figure 1 Fractional extraction is carried out in the fractionation extraction device shown (17 stages of extraction section and 3 stages of washing section), the raffinate is collected, water and organic solvent are removed by vacuum concentration, washed with water and dried to obtain the final product. Through HPLC analysis, the absolute purity of capsaicin in the final product is 98.3%, the relative content of capsaicin:dihydrocapsaicin is 98.8:1.2, and the yield is 99.0%.

Embodiment 3

[0050] Extract the chili peel powder with ethanol several times, concentrate the filtrate, add alcohol with a volume fraction of 70% and stir under warm conditions, and obtain capsaicin and dihydrocapsaicin after concentration and distillation of dilute alcohol dissolved in capsaicin compounds The total weight percentage is the solid capsaicin compound of 78%, and the solid capsaicin compound that obtains is made into the stock solution that capsaicin compound concentration is 85 grams per liter with acetonitrile, with n-hexane / ethyl acetate binary mixed solvent (wherein acetic acid The molar fraction of ethyl ester is 5%) as extractant, with acetonitrile as washing agent, the flow ratio between raw material liquid, extractant, washing agent three is 2.6: 27: 1, at 45 ℃ figure 1 Fractional extraction is carried out in the fractionation extraction device shown (16 stages in extraction section and 8 stages in washing section), the raffinate is collected, water and organic solvent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com