Phase change material microcapsule coated by thermoset phenolic resin and preparation method thereof

A technology of phase change material and phenolic resin, which is applied in the direction of microcapsule preparation, heat exchange material, microsphere preparation, etc. It can solve the problems of poor durability, low phase change heat, and low mixing amount, and achieve good coating effect , the effect of high phase change heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

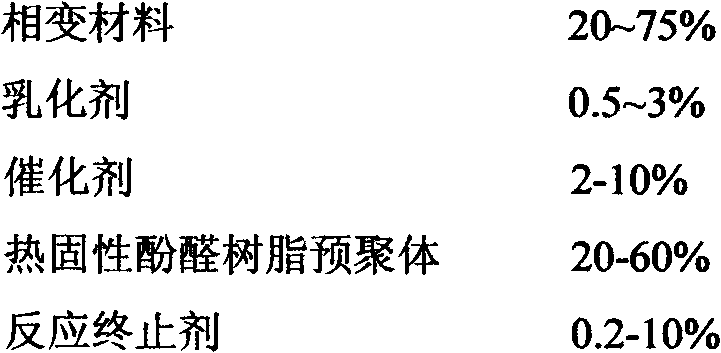

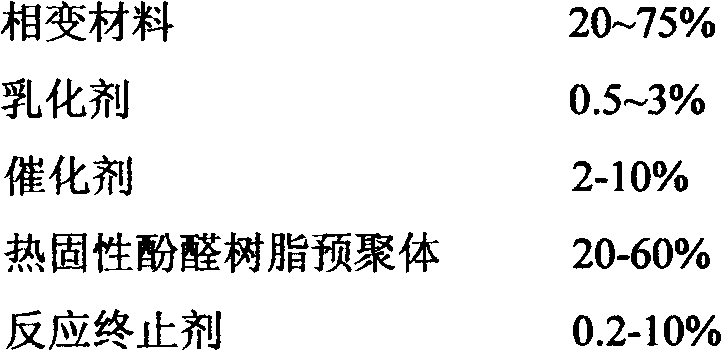

Method used

Image

Examples

Embodiment 1

[0040] Step 1, weighing 100g of n-octadecane, heating at 40°C until completely melted;

[0041] Step 2, adding 4 g of alkylphenol polyoxyethanol ether, 150 g of distilled water, and 8 g of 48% aqueous sodium hydroxide solution to the molten n-octadecane and mixing to form an emulsion;

[0042] Step 3, put the emulsion into an ultrasonic cleaner and vibrate ultrasonically until the particle size of the emulsion reaches 1-1000 microns;

[0043] Step 4, move the emulsion that step 3 obtains into a four-mouth container that includes agitator, thermocouple, condenser tube and feeding port;

[0044] Step 5, place the four-mouth container containing the emulsion in step 4 in the intelligent temperature-controlled electric heating mantle, start stirring and heating;

[0045] Step 6, weighing 100 g of a thermosetting phenolic resin prepolymer with an average degree of polymerization of 2 and a terminal methylol content of 20 wt %;

[0046] Step 7, mechanically stirring the emulsion i...

Embodiment 2

[0055] Step 1, weigh 120g of 44# paraffin and heat at 60°C until completely melted;

[0056] Step 2, add sodium dodecylbenzene sulfonate 5g, distilled water 200g, triethylamine 8g to the 30# paraffin of melting and mix to form an emulsion;

[0057] Step 3, put the emulsion into an ultrasonic cleaner and vibrate ultrasonically until the particle size of the emulsion reaches 1-1000 microns;

[0058] Step 4, move the emulsion that step 3 obtains into a four-mouth container that includes agitator, thermocouple, condenser tube and feeding port;

[0059] Step 5, place the four-mouth container containing the emulsion in step 4 in the intelligent temperature-controlled electric heating mantle, start stirring and heating;

[0060] Step 6, weighing 110 g of a thermosetting phenolic resin prepolymer with an average degree of polymerization of 2 and a terminal methylol content of 20 wt %;

[0061] Step 7, mechanically stirring the emulsion in step 5 and heating it to 70° C., slowly addi...

Embodiment 3

[0070] Step 1, weigh 100 g of mixed fatty acids (66wt% lauric acid+34wt% myristic acid), and heat at 60°C until completely melted;

[0071] Step 2, add emulsifier styrene-maleic anhydride sodium salt emulsion 4g, distilled water 150g, monoethanolamine 8g to the beaker that step 1 is equipped with mixed fatty acid and mix to form emulsion;

[0072] Step 3, the emulsion is put into a homogenizer and mixed at 4000 Rpm until the emulsion droplet size reaches 1-1000 microns;

[0073] Step 4, move the emulsion that step 3 obtains into a four-mouth container that includes agitator, thermocouple, condenser tube and feeding port;

[0074] Step 5, place the four-mouth container containing the emulsion in step 4 in the intelligent temperature-controlled electric heating mantle, start stirring and heating;

[0075] Step 6, weighing 125 g of a thermosetting phenolic resin prepolymer with an average degree of polymerization of 3 and a terminal methylol content of 10 wt %;

[0076] Step 7,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com