Method for preparing polymer electrode material for supercapacitor

A technology for supercapacitors and electrode materials, applied in the field of capacitors, can solve the problems of low volume energy density of supercapacitors, and achieve the effects of reducing ion transmission impedance, improving cycle life, and reducing polarization impedance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

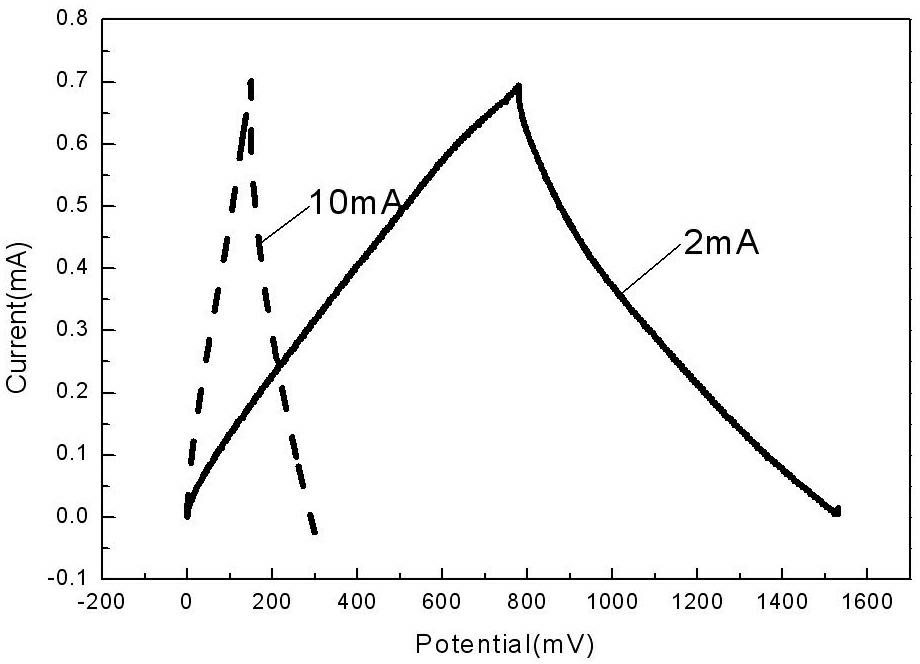

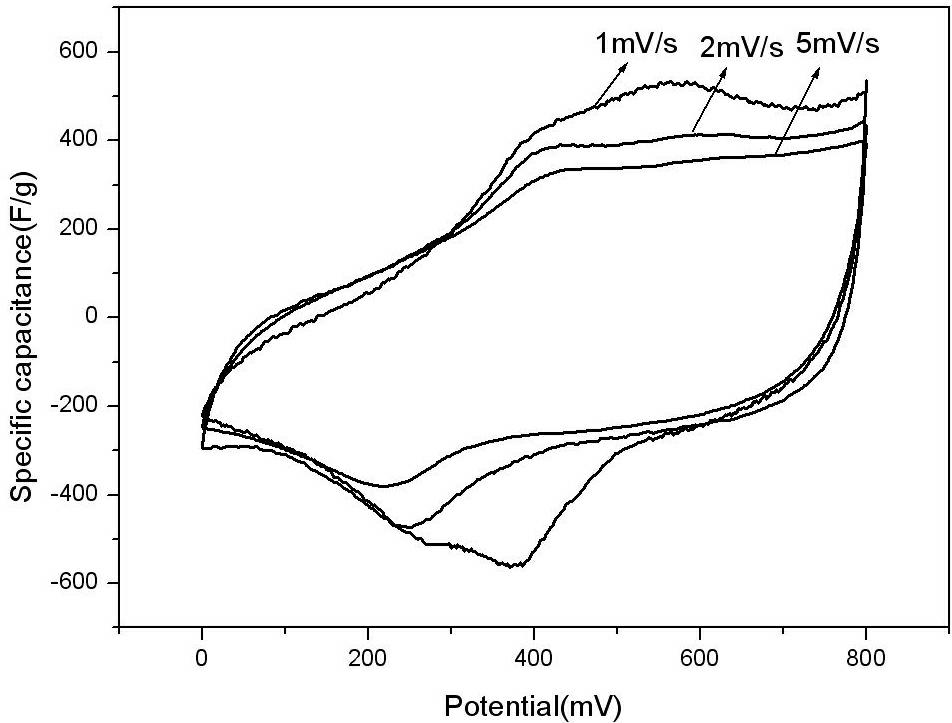

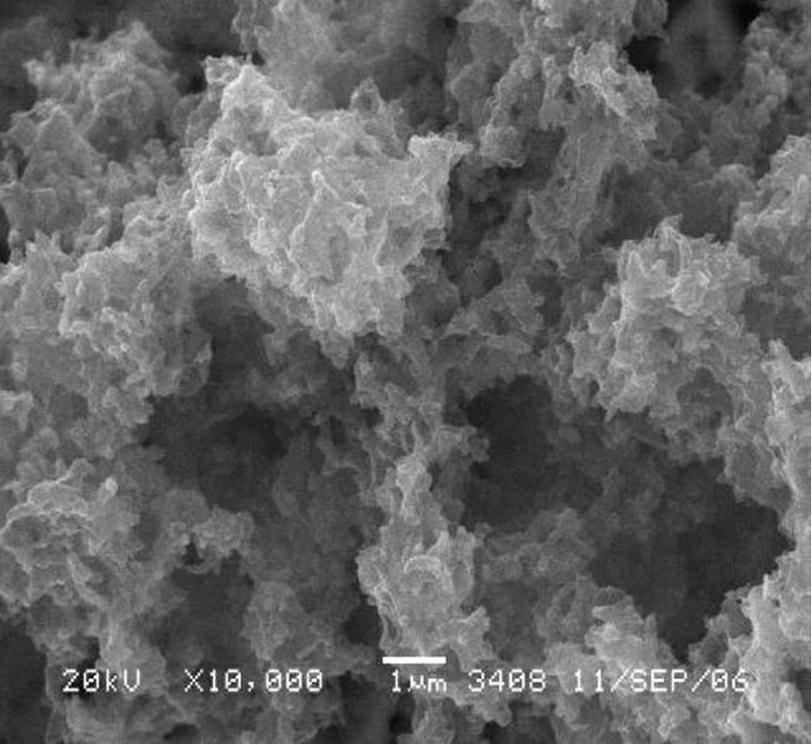

Image

Examples

Embodiment 1

[0027] First use 100g nano carbon black with 20%HNO 3 Repeated washing, filtering and washing until the washing water is neutral, add 460ml of aniline monomer and 1100g of ammonium persulfate to 1L of 1M hydrochloric acid solution, stir well, add carbon black to the mixed solution of aniline monomer and hydrochloric acid, and add Dispersant Dispersed with a small amount of ethanol, ultrasonically dispersed for 0.5h, so that the carbon black is completely dispersed in the aniline solution, transferred to an ice bath for stirring, and the temperature is controlled below 4°C; at the same time, slowly drop into the hydrochloric acid solution in which ammonium persulfate is dissolved. When the titration started, a black-green precipitate appeared in the container, the reaction time was controlled to be 5 hours, and the mass percentage of carbon black in the composite electrode material was 5%. After the reaction is over, filter the precipitate, wash it with deionized water until it...

Embodiment 2

[0030] Others are the same as in Example 1, except that the pyrrole monomer is replaced by aniline monomer, and the filtered precipitate is dried at 70° C. for 40 hours.

Embodiment 3

[0032] Others are the same as in Example 1, except that the dispersant ethanol is replaced by a mixed solution of acetone and ethanol, and the filtered precipitate is dried at 60° C. for 30 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com