Device and method for biologically manufacturing succinic acid by continuous crystallization

A bio-manufacturing, succinic acid technology, applied in the field of succinic acid fermentation and separation and purification, can solve the problems of low time yield, low production efficiency, lower product concentration, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

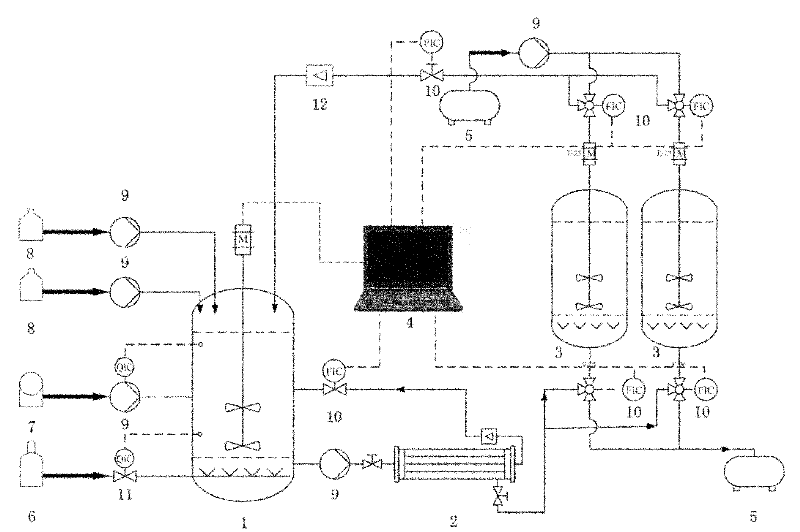

[0054] Such as figure 1 The bioreactor shown is a fermenter with automatic temperature control, pH adjustment, and feeding. The microorganism selected for fermentation is Actinobacillus succinogenes, also known as 130Z T , deposited in the American Type Culture Collection (ATCC), number ATCC55618. The preparation of the medium: the preservation medium and the activation medium are nutrient-rich TSB medium; the seed medium formula (unit: g / L) glucose 10, yeast powder 6, NaCl 1, MgCl 2 2. CaCl 2 1.5, Na 2 HPO 4 2.9, NaH 2 PO 4 2.2; Seed medium formula (unit: g / L) glucose 30, yeast powder 15, urea 2, KCl 4, MgCl 2 2. MnCl 2 0.07, CaCl 2 1.5, Na 2 HPO 4 4.4, NaH 2 PO 4 3.3, adjust the pH value to 6.4-6.9, and sterilize at 121°C for 30 minutes.

[0055] Under aseptic operation conditions, seed liquid is added to the fermentation liquid, and the volume percentage of the inoculum is 5-7%. At this time, the amount of succinic acid is 0, the stirring is started, the rota...

Embodiment 2

[0059] By adjusting the acidity of the crystallization tank system, the distribution percentages of succinic acid and succinate, by-product organic acids (formic acid, lactic acid, acetic acid) and their salts can be controlled. The degree of dissociation of carboxylic acids in different pH environments is calculated according to their respective dissociation constants, such as acetic acid (K a =6.2×10 -5 ), formic acid (K a =2.1×10 -4 ), lactic acid (K a =1.37×10 -4 ) succinic acid (K a1 =2.1×10 -4 , K a2 =2.3×10 -6 ). The free acid / acid ion distribution diagram of a monobasic acid is calculated according to the following formula:

[0060] δ HA = [ HA ] [ HA ] + [ A - ] = 1 ...

Embodiment 3

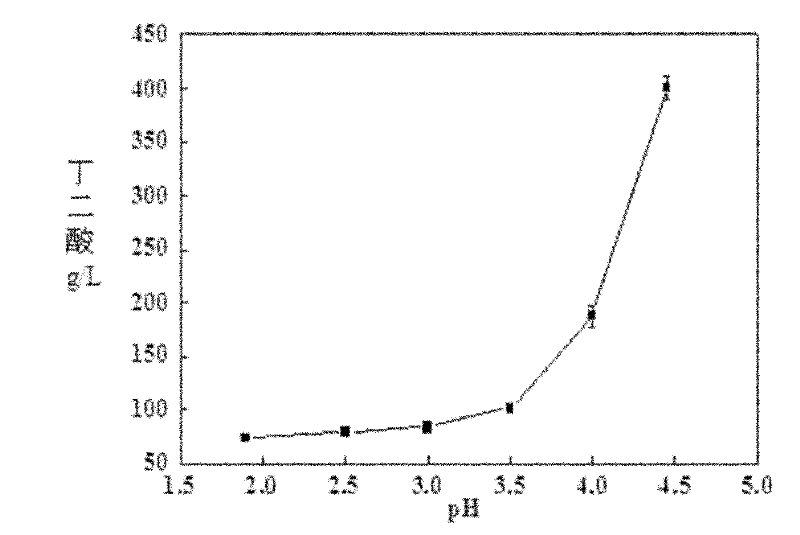

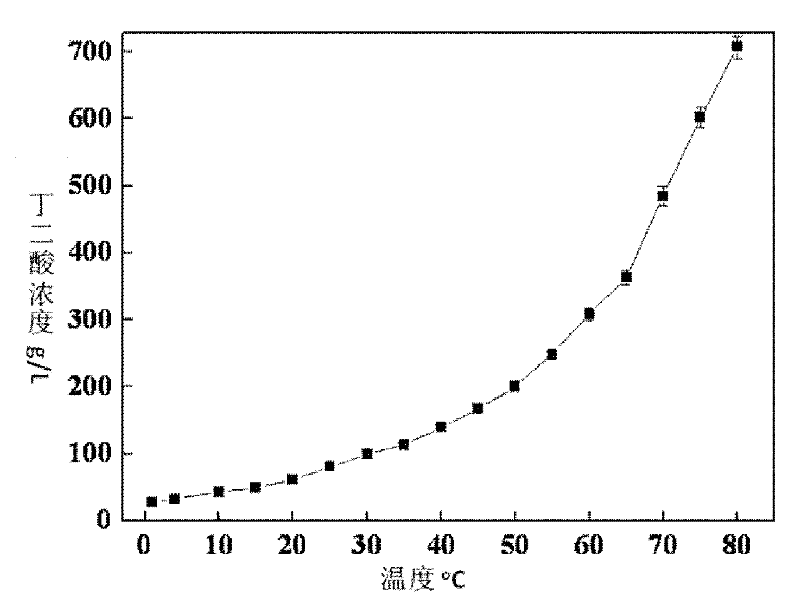

[0069] The solubility determination of succinic acid and succinate is carried out under normal pressure, and the temperature is controlled at 0-100°C. The solubility of succinic acid and succinate is calculated according to saturated succinic acid / succinate under specific conditions concentration in solution. HCl and NaOH are used to adjust the mother liquor pH. Such as figure 2Shown is the solubility distribution of succinic acid at different pH at 25°C (room temperature), the solubility of succinic acid in different pH ranges at room temperature, with the decrease of pH, the solubility of succinic acid also drops sharply. Formic, acetic, and lactic acids, whether as acid molecules or acid radical ions, are miscible with water in all pH ranges above freezing; image 3 shows the solubility distribution of succinic acid at different temperatures, Figure 4 shows the solubility distribution of sodium monohydrogen succinate at different temperatures, Figure 5 The solubility...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com