Oxalate hydrogenated Au-Ag bimetallic catalyst and preparation method thereof

A metal catalyst, oxalate technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of increasing production links and product insecurity, chromium To deal with problems such as high cost, to achieve the effect of easy scale-up production, simple preparation process and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

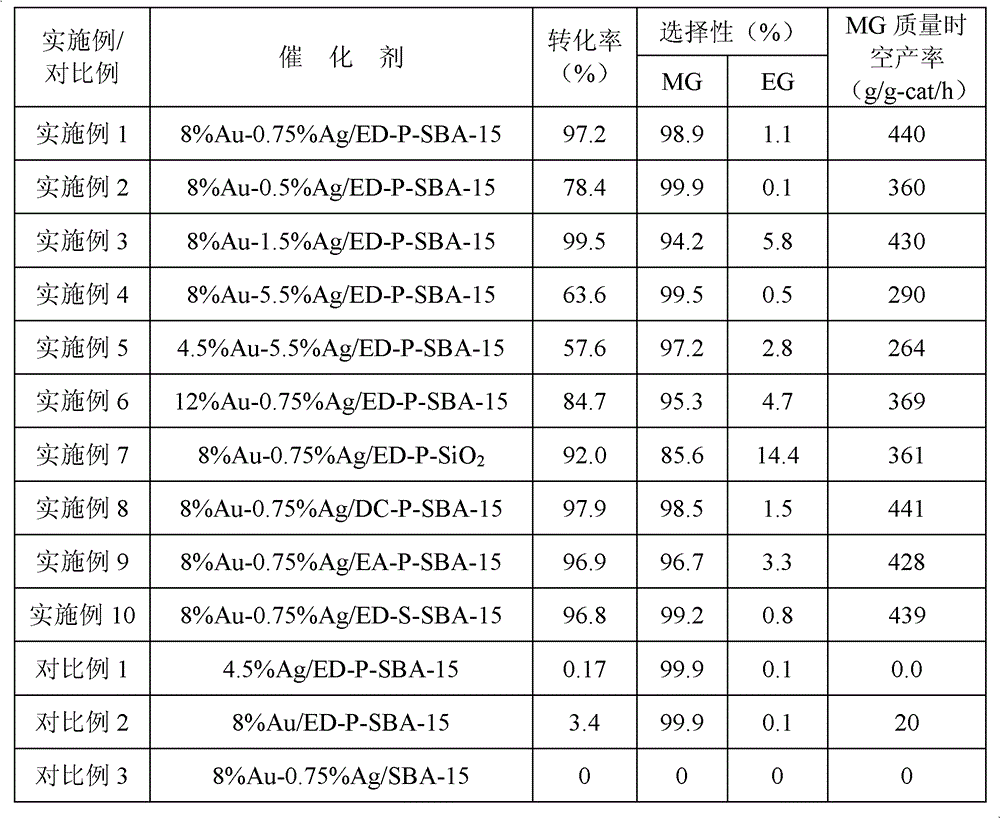

Embodiment 1

[0028] 1) The surface area prepared in the laboratory is 833m 2 / g of SBA-15 carrier 3.0g.

[0029] 2) Dissolve 0.5 g of PVA completely in 30 mL of tetrahydrofuran, pour the above-mentioned carrier into the solution, let it stand for 4 hours, filter, wash and dry to obtain the P-SBA-15 product, which is ready for use.

[0030] 3) Add 0.3g of ethylenediamine (ED) and 30ml of deionized water to the above P-SBA-15 product, heat at 90°C for 12h, cool to room temperature, rinse with deionized water, and dry under vacuum at 60°C to obtain functional group ED-P-SBA-15 solid powder A, spare.

[0031] 4) At room temperature, use a pipette to pipette 18.5mL of chloroauric acid solution with a concentration of 0.01g / mL, add 50ml of deionized water to dilute to obtain an orange-yellow solution, and add 1.0g of functionalized ED-P-SBA under stirring -15 solid powder A, after stirring for 10 minutes, add 20 mL of 0.005 g / mL sodium borohydride aqueous solution dropwise while stirring, afte...

Embodiment 2

[0039] The preparation method of the catalyst is the same as in Example 1, changing the 0.01g / mL silver nitrate solution to 0.85mL, and keeping the other compositions unchanged, to prepare the 8%Au-0.5%Ag / ED-P-SBA-15 catalyst.

[0040] ICP-MS quantitative analysis results show that the content of Au and Ag is within the error range of the theoretical loading; after nitrogen adsorption test, the specific surface area is 564m 2 / g, the pore volume is 0.80ml / g, and the average pore diameter is 5.3nm. The performance evaluation and analysis conditions of the catalyst for the hydrogenation of dimethyl oxalate are the same as in Example 1, and the results are shown in Table 1.

Embodiment 3

[0042] The preparation method of the catalyst was the same as in Example 1, changing the 0.01g / mL silver nitrate solution to 2.55mL, and keeping the other compositions unchanged, to prepare the 8%Au-1.5%Ag / ED-P-SBA-15 catalyst.

[0043] ICP-MS quantitative analysis results show that the content of Au and Ag is within the error range of the theoretical load; after nitrogen adsorption test, the specific surface area is 555m 2 / g, the pore volume is 0.76ml / g, and the average pore diameter is 5.4nm. The performance evaluation and analysis conditions of the catalyst for the hydrogenation of dimethyl oxalate are the same as in Example 1, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com