Double foam pumping insulation slurry and manufacturing method

A thermal insulation slurry and double foaming technology, which is applied in the field of building thermal insulation materials, can solve the problems of unrealized mechanized production and pumping process of double foam thermal insulation slurry, and achieve the optimization of economic and technical indicators and good performance-price ratio , good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

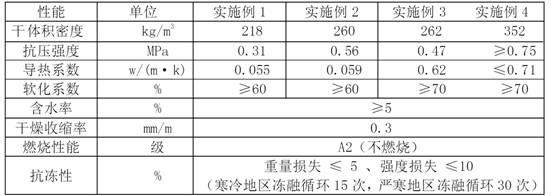

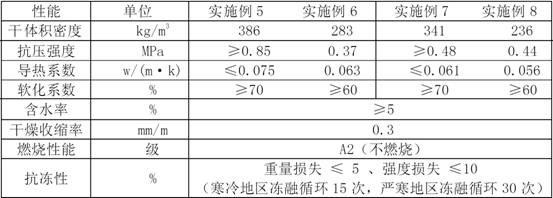

Examples

Embodiment 1

[0034] Expandable polystyrene (particle size Φ=1mm) is steam-foamed, and portable benzene particle foaming equipment is used at the construction site to make polystyrene foam particles with an average particle size of 4.5mm (expansion ratio>90 ).

[0035] Formula (according to 1m 3Count): polyphenylene foamed particle stack volume 0.8m 3 ; Ordinary Portland cement (400 # ) 180kg; cement foaming agent 1.1kg; water 100kg.

[0036] The cement foaming agent is prepared in the factory, and its formula is calculated by 100kg: water 70kg, sodium hydroxide 0.4kg, rosin 0.6kg, bone glue 15kg, fatty alcohol polyoxyethylene ether sodium sulfate (AES) surfactant 14kg; Its preparation The process is to dissolve sodium hydroxide in water first, then add rosin powder and heat to 70-80°C, stir until completely dissolved, then add bone glue powder without stirring for 20-30 minutes, then cool down to below 50°C, and finally add AES and stir Fully dissolve to make concentrated cement foamin...

Embodiment 2

[0039] The recovered waste benzene board is crushed with a crusher to make polystyrene foamed particles with an average particle size of 2-5mm, and at the same time, the cement foaming agent is purchased from the market.

[0040] Formula (according to 1m 3 Count): polyphenylene foamed particle stack volume 0.7m 3 ; Magnesium oxide 100kg; Magnesium chloride (halogen grains) 50kg; Cement foaming agent 1.2kg; Water 85kg.

[0041] The cement foaming agent is prepared in the factory, and its formula is calculated by 100kg: water 67kg, sodium hydroxide 0.3kg, rosin 2.7kg, bone glue 15kg, fatty alcohol polyoxyethylene ether sodium sulfate (AES) surfactant 15kg; Its preparation The process is to dissolve sodium hydroxide in water first, then add rosin powder and heat to 70-80°C, stir until completely dissolved, then add bone glue powder without stirring for 20-30 minutes, then cool down to below 50°C, and finally add AES and stir Fully dissolve to make concentrated cement foaming ag...

Embodiment 3

[0044] The phenolic foamed board was crushed by a crusher at the construction site to make polystyrene foamed particles with an average particle size of 5 mm.

[0045] Formula (according to 1m 3 Count): phenolic foamed particle stack volume 0.8m 3 ; Ordinary Portland cement (400 # ) 210kg; cement foaming agent 0.9kg; water 120kg.

[0046] The cement foaming agent is prepared in the factory, and its formula is calculated by 100kg: water 72kg, sodium hydroxide 0.3kg, rosin 2.7kg, bone glue 15kg, fatty alcohol polyoxyethylene ether sodium sulfate (AES) surfactant 10kg; its preparation The process is to dissolve sodium hydroxide in water first, then add rosin powder and heat to 70-80°C, stir until completely dissolved, then add bone glue powder without stirring for 20-30 minutes, then cool down to below 50°C, and finally add AES and stir Fully dissolve to make concentrated cement foaming agent, and add water to dilute it when used on the construction site.

[0047] Through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com