High iron slag power doped wave-absorbing foam concrete and preparation method thereof

A technology of foam concrete and iron ore slag powder, which is applied in the cross field of building material science and electromagnetic science, can solve the problems of high cost, high material density, and inability to take into account thermal insulation performance, etc., so as to improve the wave-absorbing ability and good wave-absorbing performance , Improve the effect of electromagnetic performance and impedance matching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 foam concrete design bulk density 400kg / m 3 , thickness is 25mm

[0031] ① Mix 5g of calcium carbonate whiskers, 300g of high iron slag powder, and 700g of ordinary portland cement, and stir evenly to obtain material Ⅰ;

[0032] ②Mix 10g of animal and vegetable protein composite foaming agent with 200g of water, and make foam for 3 minutes to obtain foam;

[0033] ③Mix material I, 10g polycarboxylate superplasticizer and 300g water to obtain a slurry;

[0034] ④ Mix the foam with the slurry and stir evenly to obtain material II;

[0035] ⑤ Mold casting: inject material II into the mold, shake it flat, and cure it in a cement curing box with a temperature of 20±2°C and a relative humidity of >95% for 24 hours;

[0036] ⑥ demoulding;

[0037] ⑦Curate in a curing room at 20±2°C and relative humidity >95% until 28 days old.

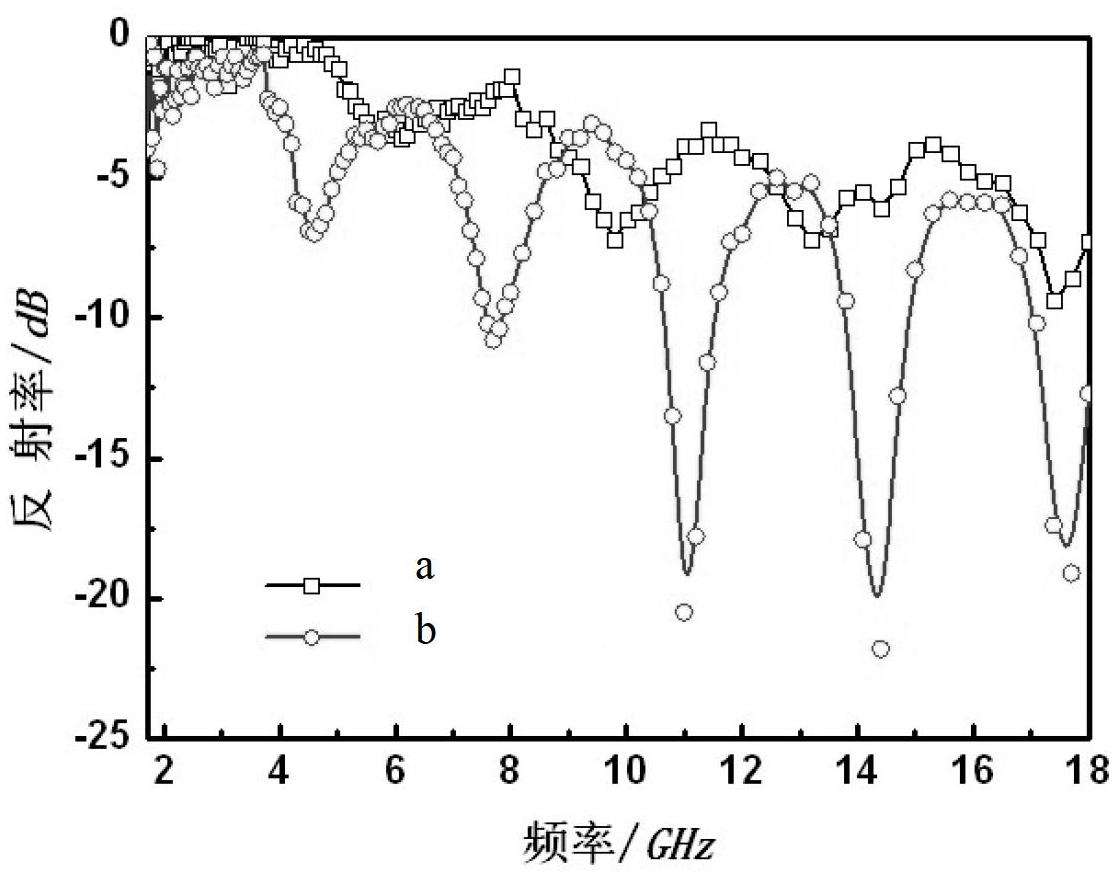

[0038] Dry the product in an electric blast drying oven at 60°C for 24 hours before performing a performance test. The thermal conducti...

Embodiment 2

[0039] Example 2 Foam concrete design bulk density 500kg / m 3 , thickness is 25mm

[0040] ① Mix 5g of carbon nanotubes, 200g of high iron slag powder, and 800g of ordinary portland cement, and stir evenly to obtain material Ⅰ;

[0041] ②Mix 10g of animal and vegetable protein composite foaming agent with 100g of water, and make foam for 3 minutes to obtain foam;

[0042] ③Mix the material I, 10g of polycarboxylate superplasticizer and 400g of water to obtain a slurry;

[0043] ④ Mix the foam with the slurry and stir evenly to obtain material II;

[0044] ⑤ Mold casting: inject material II into the mold, shake it flat, and cure it in a cement curing box with a temperature of 20±2°C and a relative humidity of >95% for 24 hours;

[0045] ⑥ demoulding;

[0046] ⑦Curate in a curing room at 20±2°C and relative humidity >95% until 28 days old.

[0047] Dry the product in an electric blast drying oven at 60°C for 24 hours before performing a performance test. The thermal conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com