Preparation method of silicon carbide fibers with silicon nitride surface layer

A technology of silicon carbide fiber and silicon nitride, which is applied in the field of preparation of silicon carbide fiber, can solve the problems of reducing the mechanical properties and absorbing ability of the fiber, the difficulty of uniform and continuous coating of deposited thickness, and incomplete coating of fiber coating, etc. Achieve the effects of convenient implementation, low manufacturing cost, high temperature resistance and good oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This embodiment includes the following steps:

[0021] (1) Put the polysilane in the reaction kettle, vacuumize it five times, fill it with 99.999% high-purity nitrogen, heat it to 400°C for 2 hours, dissolve the crude product in toluene and filter it, then heat the filtrate to 300°C for reduction Pressure distillation, removal of solvent and low molecular substances, cooling to obtain polycarbosilane (PCS);

[0022] (2) Place the polycarbosilane obtained in step (1) in the melting drum of the melt spinning device, heat it to 300°C under the protection of high-purity nitrogen with a purity of 99.999%, and wait until it is completely melted into a uniform melt, then heat it at 280°C , under 0.4MPa, draw at a speed of 300m / min to obtain continuous PCS fibers;

[0023] (3) Place the continuous PCS fiber obtained in step (2) in a non-melting treatment device, vacuumize it, and fill it with high-purity nitrogen gas with a purity of 99.999%. After repeating three times, pass...

Embodiment 2

[0028] This embodiment includes the following steps:

[0029] Step (1) and (2) are operated with embodiment 1;

[0030](3) Place the continuous PCS fiber obtained in step (2) in a non-melting treatment device, heat it to 220 °C in an air atmosphere at a heating rate of 15 °C / hour, and heat-preserve and oxidize it for 4 hours to obtain a non-melting fiber;

[0031] (4) Place the non-melting fibers obtained in step (3) in a high-temperature atmosphere furnace, and raise the temperature to 1000°C at a rate of 150°C / hour in a mixed atmosphere of ammonia gas and nitrogen gas (volume ratio 1:1). Insulated at 1200°C for 2 hours to obtain Si 3 N 4 Surface SiC fiber.

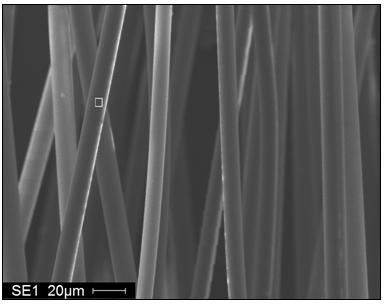

[0032] The EDX analysis of the surface layer of the continuous SiC fiber obtained in this embodiment shows that the surface of the fiber is a silicon nitride structure, and the fiber diameter is 12 m, the tensile strength is 2.1GPa, the Young's modulus is 260GPa, the fiber oxygen content is 0.95wt%, the nitrogen con...

Embodiment 3

[0034] This embodiment includes the following steps:

[0035] Step (1) and (2) are operated with embodiment 1;

[0036] (3) The continuous PCS fiber obtained in step (2) is placed in an electron accelerator irradiation box, and after the irradiation dose reaches 10MGy, it is annealed to obtain an electron beam irradiation infusible fiber.

[0037] (4) Place the electron beam irradiated non-melting fibers obtained in step (3) in a high-temperature atmosphere furnace, and raise the temperature to 700 °C at a rate of 160 °C / hour in a mixed atmosphere of ammonia gas and argon gas (volume ratio 1:1). ℃, insulated at 1300℃ for 2h to obtain 3 N 4 Continuous SiC fibers on the surface.

[0038] The continuous SiC fiber that present embodiment makes, surface EDX analysis shows that fiber surface is silicon nitride structure, and fiber diameter is 11 m, the tensile strength is 2.6GPa, the Young's modulus is 285GPa, the fiber oxygen content is 0.62wt%, the nitrogen content is 4.36wt%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com