Preparation method of aqueous nano-pigment dispersion liquid

A nano-pigment and dispersion liquid technology, which is applied in the direction of pigment paste, organic dyes, and photosensitive materials used in optomechanical equipment, etc. It can solve the problems of high cross-linking density, soft and soft coating film, and difficulty in meeting the hardness requirements. , to achieve the effect of improving developing efficiency, excellent color characteristics, and overcoming environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

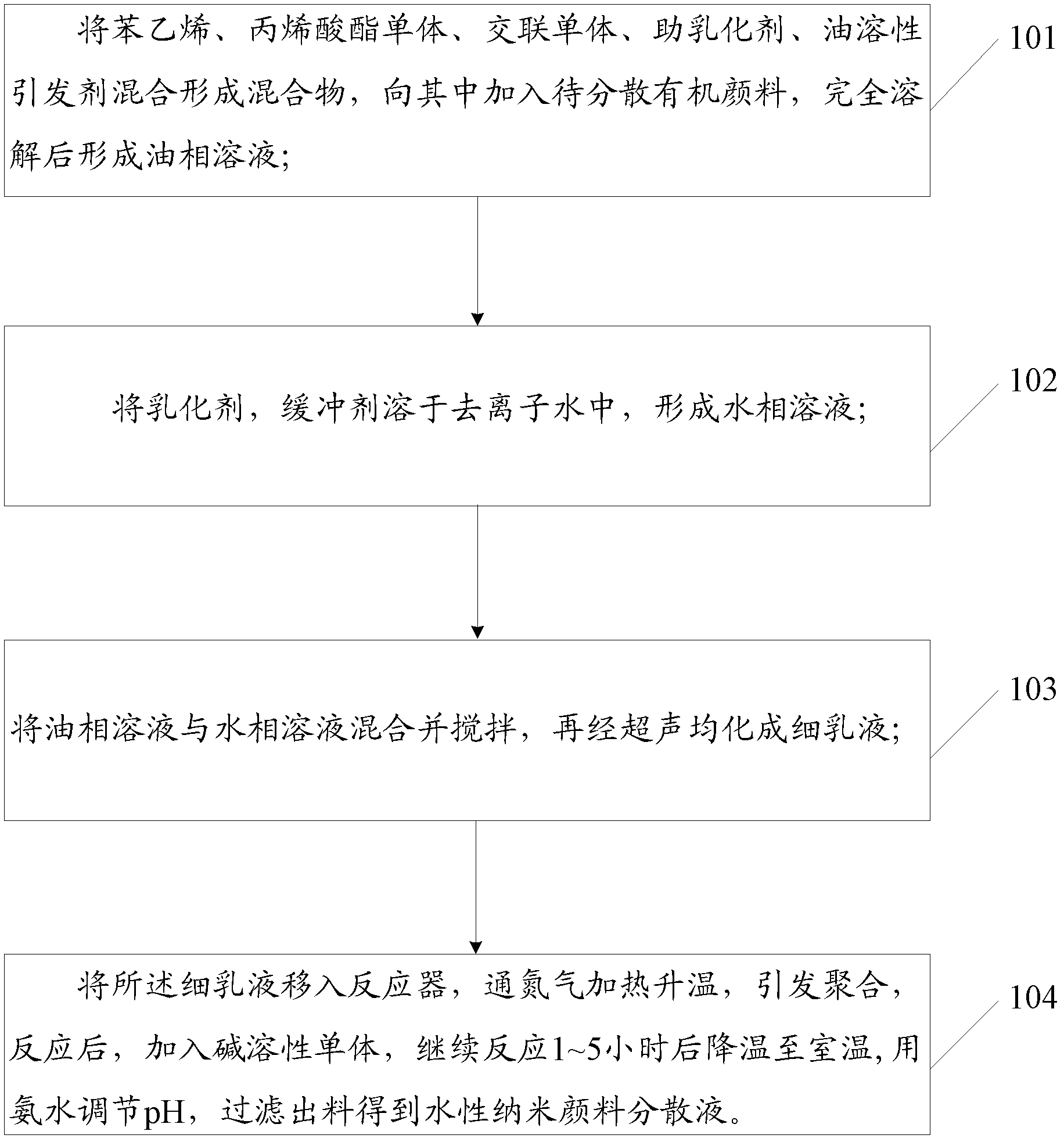

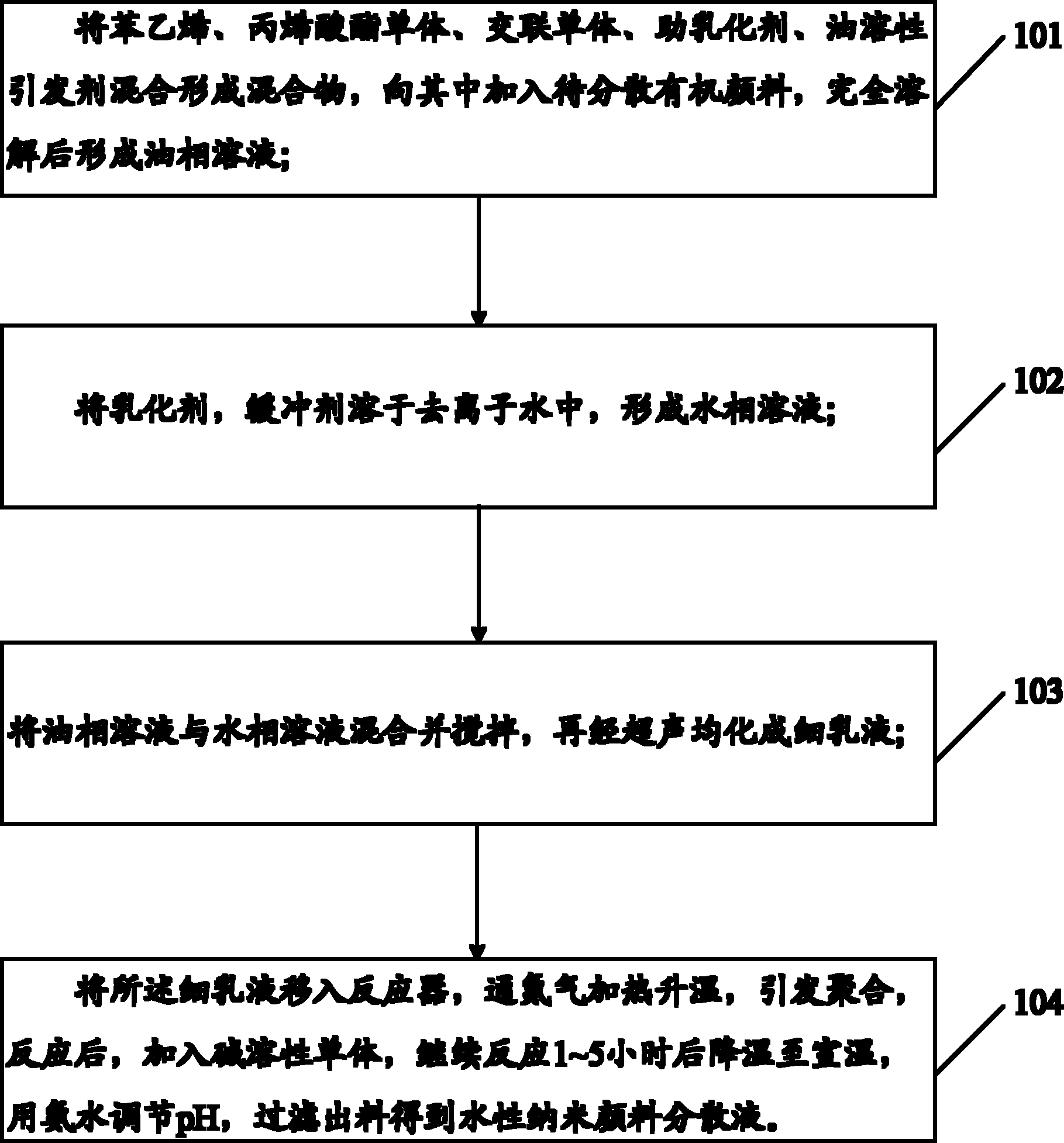

[0030] The embodiment of the present invention provides a kind of preparation method of aqueous nano pigment dispersion liquid, as figure 1 As shown, the method includes:

[0031] 101. Distilling 2.5%-40% by weight of styrene to remove polymerization inhibitors, 2.5%-20% by weight of acrylate monomers, 0.25%-5% by weight of cross-linking monomers, 0.05% ~ 0.5% co-emulsifier and 0.05% ~ 0.5% oil-soluble initiator are mixed to form a mixture, 0.25% ~ 2.5% organic pigment to be dispersed is added to it, and an oil phase solution is formed after the organic pigment is completely dissolved.

[0032] In order to realize the dispersion of organic pigments in the water phase, the oil phase solution is dispersed into the water phase solution prepared in the following steps at a nanoscale to form small droplets with a particle size of less than 100nm. Soluble pigments. The acrylate monomer used is at least two of n-butyl acrylate, isooctyl acrylate, methyl acrylate, ethyl acrylate, me...

Embodiment 2

[0050] Embodiments of the present invention provide a method for preparing an aqueous nanopigment dispersion, the method comprising:

[0051] 30g of styrene, 10g of n-butyl acrylate, 5g of methyl methacrylate, 1.3g of 1,6-hexanediol diacrylate, 1.7g of tripropylene glycol diacrylate, 1g of cetyl alcohol, were removed by distillation of 30g of polymerization inhibitor. 0.5g of benzoyl peroxide was mixed to form a mixture, and then 1.8g of the organic pigment to be dispersed was dissolved in the above mixture, and an oil phase solution was formed after completely dissolving.

[0052] In order to realize the dispersion of organic pigments in the water phase, the oil phase solution is dispersed into the water phase solution prepared in the following steps to form small droplets with a particle size of less than 100nm at the nanoscale. The embodiments of the present invention use styrene and n-butyl acrylate Monomers and methyl methacrylate monomers dissolve pigments.

[0053] In ...

Embodiment 3

[0069] Embodiments of the present invention provide a method for preparing an aqueous nanopigment dispersion, the method comprising:

[0070] Distill 26g of styrene, 10g of methyl methacrylate, 5g of isooctyl acrylate, 1.5g of 1,6-hexanediol diacrylate, 1.5g of tripropylene glycol diacrylate, 0.8g of cetyl alcohol , 0.2g of hexadecane, 0.5g of azobisisobutyronitrile mixed to form a mixture, and then 1.6g of the organic pigment to be dispersed was dissolved in the above mixture, after complete dissolution to form an oil phase solution.

[0071] In order to realize the dispersion of organic pigments in the water phase, the oil phase solution is dispersed into the water phase solution prepared in the following steps to form small droplets with a particle size of less than 100nm at the nanoscale. The embodiments of the present invention use styrene and methyl methacrylate Ester monomers and isooctyl acrylate monomers dissolve pigments.

[0072] In the embodiment of the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com