Method for preparing high-quality gasoline and diesel oil from lignin pyrolysis oil

A lignin cracking oil and lignin technology, which is applied in the field of producing high-quality gasoline and diesel oil by using lignin cracking oil, can solve the problems of waste of resources, environmental pollution, etc., and achieve low cost, wide range of raw material sources, and ingenious and efficient coupling of the reaction process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

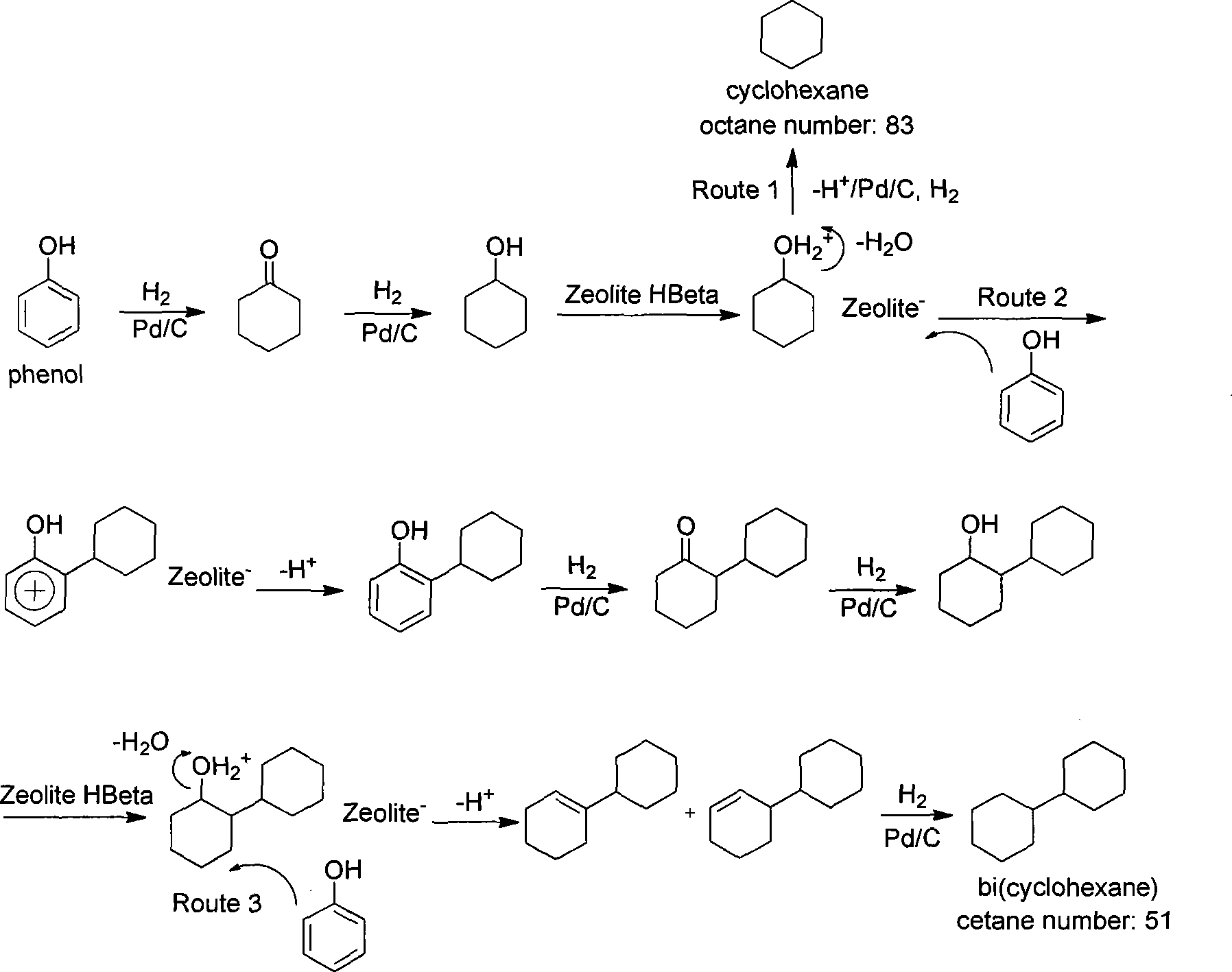

[0020] Example 1: Conversion of 4-propylphenol on different solid acids

[0021] In this example, 4-propylphenol raw material (purchased from Aldrich Company), a representative derivative of lignin, was used to test the product composition of its conversion on different solid acid catalysts. The specific method is as follows: take 0.01 mol of raw materials, add 0.04 g of Pd / C catalyst (5 wt.%, purchased from Aldrich), 2.0 g of solid acid (see Table 1), and 80 ml of water into a high-pressure Parr kettle. After ventilating with hydrogen for three times at room temperature, hydrogen is charged to 50 bar, and then the temperature is raised to 200° C. for 0.5 hour reaction, and the stirring speed is 680 rpm. After the reaction is over, it is naturally cooled to room temperature, and the product is automatically divided into two phases, the upper layer is the oil phase of the organic hydrocarbon mixture, and the lower layer is the water layer. After the organic phase was extracted wi...

Embodiment 2

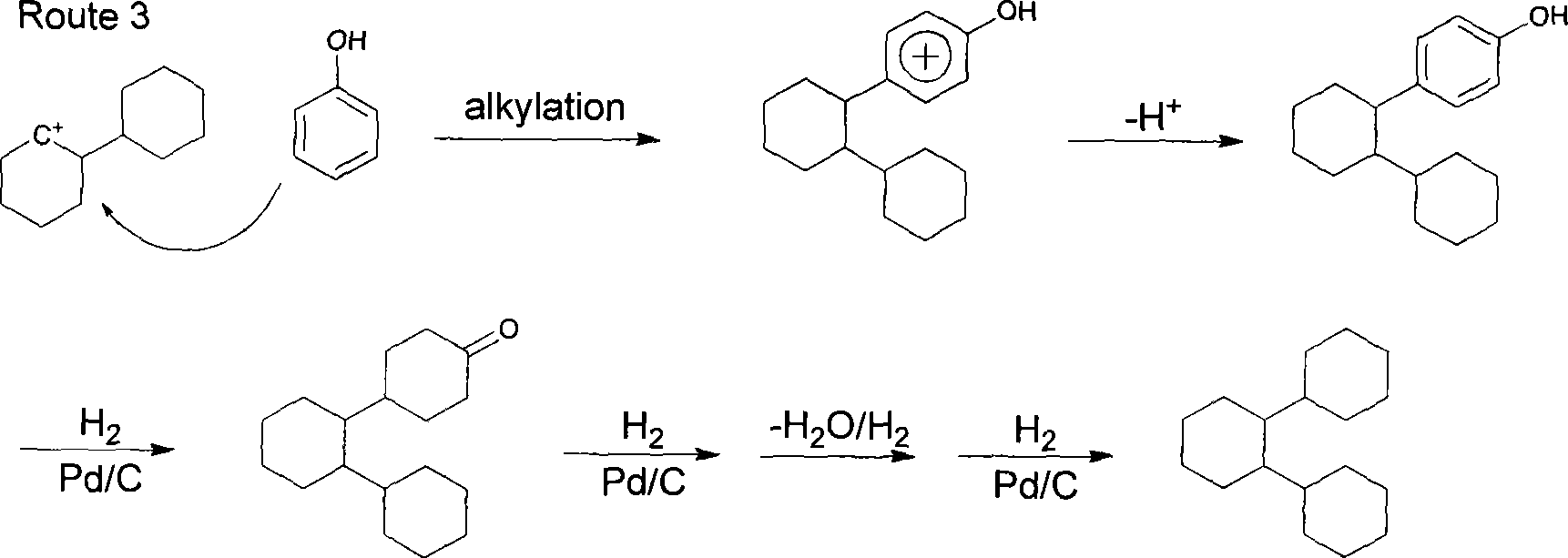

[0030] Example 2: Hydroalkylation / deoxygenation conversion using 4-propylphenol as raw material under different catalysts and conditions

[0031] In this example, 4-propylphenol, a representative derivative of lignin, was used to test its hydroalkylation and deoxygenation conversion under different catalysts and reaction conditions. The specific method is: take 0.01 mol of raw material, and 0.04g Pd / C or Pt / C or Ru / C or Pt / C catalyst (5wt.%, purchased from Aldrich) or 2.0g Ni-based catalyst (homemade), 2.0g Hβ (Si / Al=150) molecular sieve or Pd / Hβ catalyst (homemade) (see Table 2 for specific catalyst ratio), mixed with 80ml of water and added to the high-pressure Parr kettle. At room temperature, it was ventilated with hydrogen for three times and then filled with hydrogen to 50 bar, and then heated to the reaction temperature for 0.5 hours (see Table 2 for specific reaction conditions), and the stirring speed was 680 rpm. After the reaction, the product is naturally cooled to r...

Embodiment 3

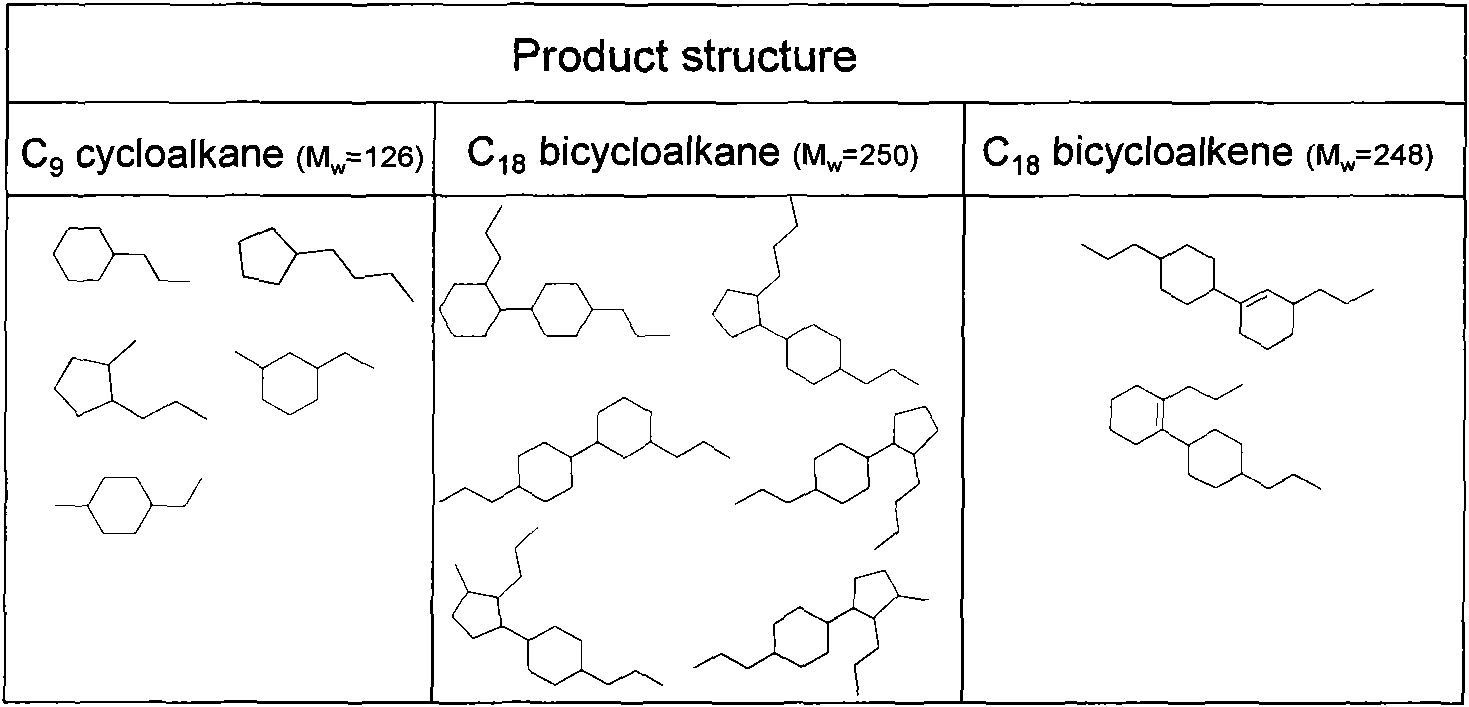

[0038] Example 3: Hydroalkylation / deoxygenation conversion using different lignin-derived phenolic compounds as raw materials

[0039] In this example, phenol, 4-methylphenol, 4-ethylphenol, 4-propylphenol, 2-methoxy-4-acetone phenol, and 2-methoxy-4 were selected as the main components of lignin pyrolysis oil. -Methylphenol, 2-methoxy-4-ethylphenol and 2-methoxy-4-propylphenol were used as raw materials to test their hydroalkylation / deoxygenation conversion activity under Pd / Hβ catalyst. The specific method is to take 0.01 mol of phenolic compound, 2.0 g of 0.1 wt.% Pd / Hβ catalyst and 80 ml of water, mix them and add them to the high-pressure Parr kettle. After replacing the reactor with hydrogen three times, it was filled with 50 bar of hydrogen under normal pressure, heated to 200°C and reacted for 2 hours, and then heated to 250°C for 0.5 hour. After the reaction, it was naturally cooled to room temperature, the organic phase was extracted with ethyl acetate, and then the qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com