Preparation method of carbon nanotube reinforced Al-matrix composite

A carbon nanotube and aluminum-based technology is applied in the field of preparation of aluminum-based composite materials, which can solve the problems of easy agglomeration and deactivation of catalysts, shortened carbon nanotube lengths, and large specific surface area of substrates, and meets the requirements of substrate morphology. Not high, reducing the oxidation of the matrix, the effect of mild reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

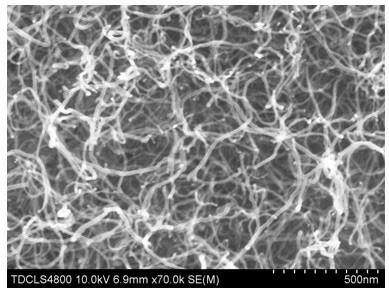

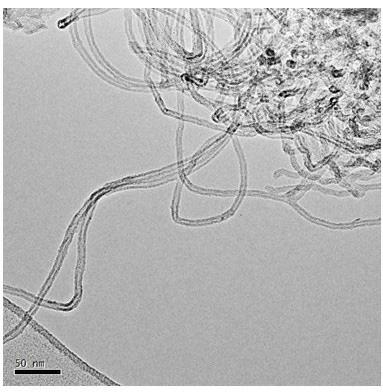

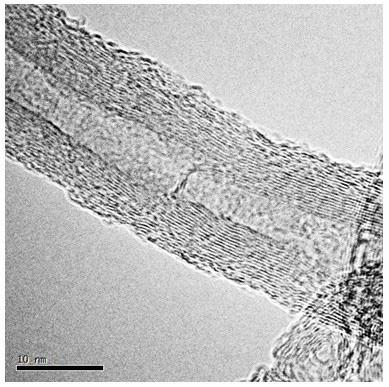

Embodiment 1

[0026] Take 0.500g of polyvinyl alcohol, add it into 200ml of deionized water, heat and dissolve to obtain a polyvinyl alcohol solution, and perform ultrasonication at room temperature for 10 minutes. Then add 20 g of laminar aluminum powder into the polyvinyl alcohol solution, stir magnetically at room temperature for 2 hours, filter and dry to obtain lamellar aluminum powder coated with polyvinyl alcohol. Dissolve 2.488g of nickel acetate tetrahydrate in 200ml of deionized water to prepare a 0.05mol / L nickel salt solution, add the above powder into the solution and stir magnetically at room temperature for 2 hours, filter and evaporate to dryness, and place in an oven to dry at 80°C Afterwards, the precursor powder is obtained. Take a certain amount of catalyst precursor powder and place it in the constant temperature zone of the tube furnace. Under the protection of argon, the temperature is raised to 250°C at a heating rate of 10°C / min, and the temperature is raised at a h...

Embodiment 2

[0028] Concrete method and step are the same as embodiment 1, and different conditions are: change raw material 2.488g nickel acetate tetrahydrate into 2.491g cobalt acetate tetrahydrate, feed the mixed gas of acetylene and argon during catalytic cracking, wherein the flow rate of acetylene is 20ml / min , the argon flow rate was 260ml / min, and finally a carbon nanotube and aluminum composite material with a carbon nanotube content of 4.12wt.% was obtained.

Embodiment 3

[0030] The specific method and steps are the same as in Example 1, except that the different conditions are: hydrogen gas instead of argon gas is introduced during the 1 hour heat preservation at 250°C, and finally a carbon nanotube and aluminum composite with a carbon nanotube content of 3.90wt.% is obtained. Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com