A post-treatment process for drying gluten

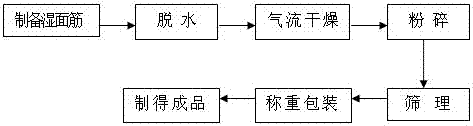

A processing technology and technology of gluten powder, which is applied in the field of post-processing processing technology of gluten powder drying, can solve problems such as difficulty in maintaining stable production volume, unstable product quality for customers, unqualified material thickness, etc., to achieve increased production and Equipment operation rate, benefit large-scale production, and reduce the effect of unqualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

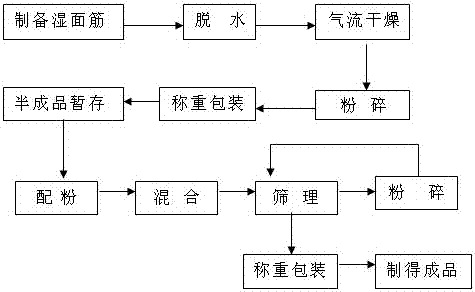

[0023] The present invention will be further described below in conjunction with accompanying drawing.

[0024] Such as figure 2 As shown, wheat flour is used as raw material, and the finished gluten powder is obtained through preparation of wet gluten→dehydration→airflow drying→crushing→weighing and packaging→semi-finished product temporary storage→powder mixing→mixing→sifting, crushing→weighing and packaging. The specific steps are as follows: (1) Preparation of wet gluten: Wheat flour is kneaded and washed to obtain relatively pure fresh wet gluten from the washed part.

[0025] (2) Dehydration: The wet gluten is passed through a special dehydration auger to remove free water to obtain gluten.

[0026] (3) Airflow drying: The gluten is dried by an airflow dryer to obtain coarse particles of semi-finished products. In order to maintain good gluten activity, set the air inlet temperature of the dryer to 150°C-160°C, and the air outlet temperature to 59°C-69°C.

[0027] (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com