Method for preparing Ag/Ag3PO4 composite photo-catalyst

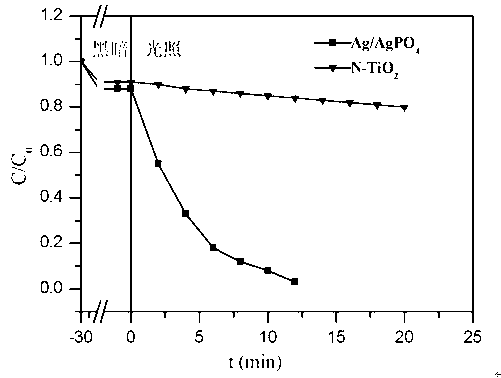

A catalyst and composite light technology, applied in the field of photocatalytic materials, can solve problems such as poor stability of photocatalysts, and achieve the effects of easy industrial production, simple operation, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

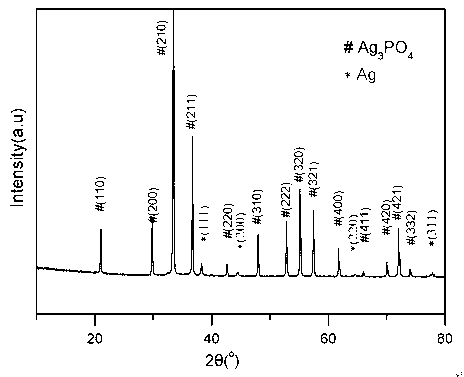

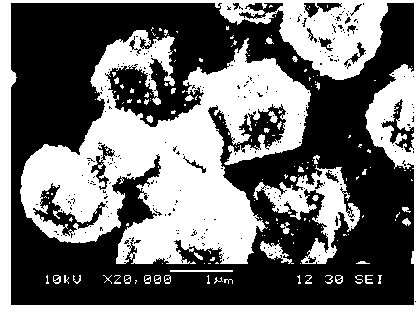

Embodiment 1

[0017] Take 30ml of AgNO with a concentration of 0.125mol / L 3 Add the aqueous solution into a reaction kettle with a volume of 75mL, then add 1ml of pyridine, stir evenly, then add 20 mL of an aqueous solution containing 0.00125 mol of trisodium phosphate, stir thoroughly for 30 minutes, then add sodium hydroxide to adjust the pH value of the mixture to 10 , the reaction kettle was sealed and placed in a constant temperature furnace, and reacted at 180°C for 3 hours. Then the reaction kettle was taken out and cooled to room temperature naturally, and then the product was filtered with suction and washed three times with distilled water and ethanol respectively. 3 PO 4 composite photocatalyst.

Embodiment 2

[0019] Take 30ml of AgNO with a concentration of 0.125mol / L 3 Add the aqueous solution into a reaction kettle with a volume of 75mL, then add 3ml of pyridine, stir evenly, then add 20 mL of an aqueous solution containing 0.00125 mol of trisodium phosphate, stir thoroughly for 30 minutes, then add sodium hydroxide to adjust the pH value of the mixture to 10 , the reaction kettle was sealed and placed in a constant temperature furnace, and reacted at 180°C for 3 hours. Then the reaction kettle was taken out and cooled to room temperature naturally, and then the product was filtered with suction and washed three times with distilled water and ethanol respectively. 3 PO 4 composite photocatalyst.

Embodiment 3

[0021] Take 30ml of AgNO with a concentration of 0.05mol / L 3 Add the aqueous solution into a reaction kettle with a volume of 75mL, then add 3ml of pyridine, stir evenly, then add 20 mL of an aqueous solution containing 0.0005 mol of disodium hydrogen phosphate, add sodium hydroxide to adjust the pH value of the mixture to 11.3, and stir thoroughly for 30 minutes , the reaction kettle was sealed and placed in a constant temperature furnace, and reacted at 120° C. for 12 hours. Then the reaction kettle was taken out and cooled to room temperature naturally, and then the product was filtered with suction and washed three times with distilled water and ethanol respectively. 3 PO 4 composite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com