Method for preparing bisphenol A molecularly imprinted polymer

A molecular imprinting and polymer technology, applied in the field of nanomaterials, can solve the problems of difficult grinding and sieving, large particles, etc., and achieve the effect of uniform particles, large surface area and controllable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

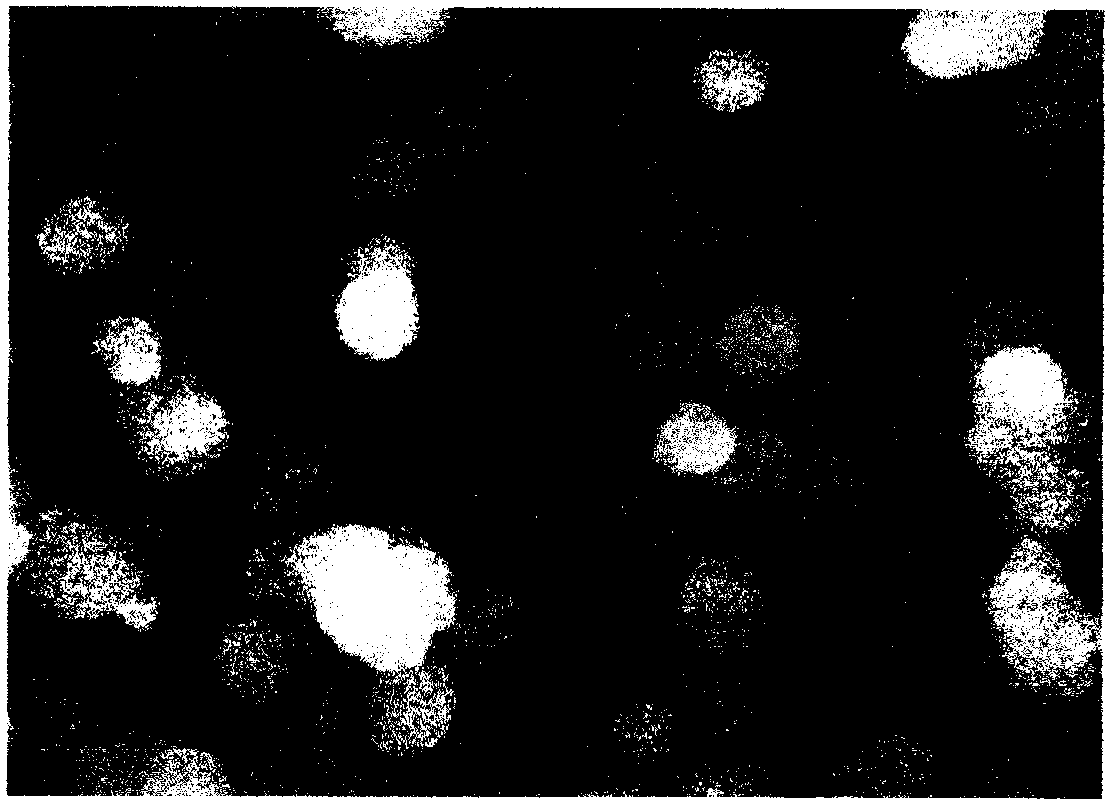

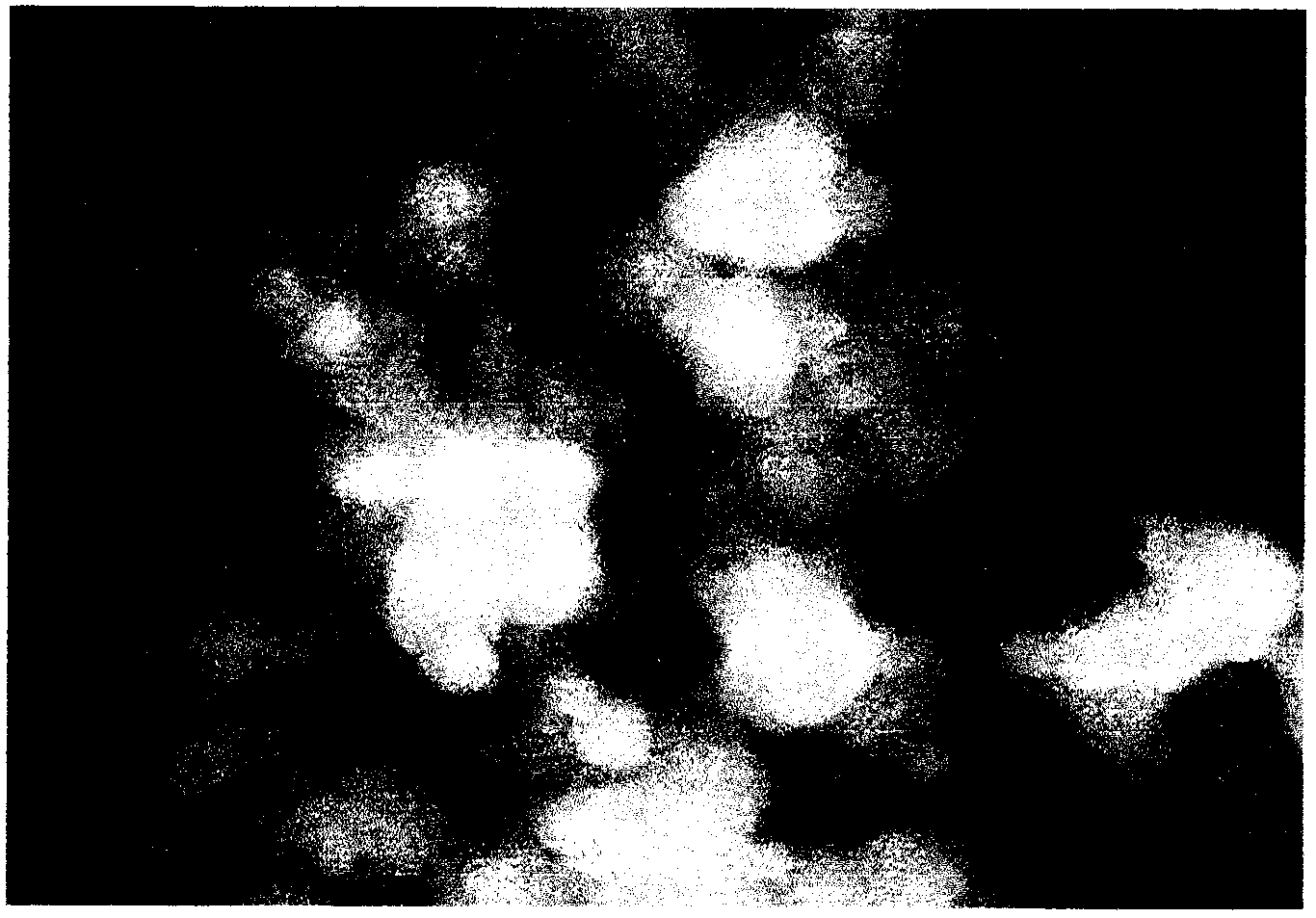

Image

Examples

Embodiment 1

[0029] Add 1mmol (228mg) bisphenol A, 4mmol (0.42mL) 2-vinylpyridine and 50mL toluene into a 150mL Erlenmeyer flask, shake at room temperature for 4h, so that bisphenol A and 2-vinylpyridine can fully act; then add 20mmol poly Glycerol trimethacrylate and 50 mg of azobisisobutyronitrile were thoroughly mixed, then ultrasonically treated for 20 minutes, nitrogen gas was passed for 10 minutes to remove dissolved oxygen, and then moved into a 60°C constant temperature water bath for thermal polymerization in a sealed state. After 24 hours, it was taken out and cooled to room temperature to obtain a colloidal polymer. After passing through a 200-mesh molecular sieve, it was extracted with 1:9 (v / v) acetic acid-methanol 200mL Soxhlet for 48h, then washed with methanol 200mL for 24h, and vacuum-dried to obtain a polymer are molecularly imprinted polymers.

Embodiment 2

[0031] Add 1 mmol (228 mg) of bisphenol A, 4 mmol (0.42 mL) of α-methacrylic acid (MAA) and 50 mL of toluene into a 150 mL Erlenmeyer flask, shake at room temperature for 4 hours, so that bisphenol A and 2-vinylpyridine can fully act; Then add 20mmol of polyglycerol trimethacrylate and 50mg of azobisisobutyronitrile, mix well and then ultrasonically treat for 20min, blow nitrogen gas for 10min to remove dissolved oxygen, and move it into a 60°C constant temperature water bath for thermal polymerization in a sealed state. After 24 hours, it was taken out and cooled to room temperature to obtain a colloidal polymer. After passing through a 200-mesh molecular sieve, it was extracted with 1:9 (v / v) acetic acid-methanol 200mL Soxhlet for 48h, then washed with methanol 200mL for 24h, and vacuum-dried to obtain a polymer are molecularly imprinted polymers.

Embodiment 3

[0033] Add 1mmol (228mg) of bisphenol A, 4mmol (0.42mL) of 2-vinylpyridine and 50mL of chloroform into a 150mL Erlenmeyer flask, and shake at room temperature for 4 hours to fully effect bisphenol A and 2-vinylpyridine; then add 20mmol of polyvinylpyridine Glycerol trimethacrylate and 50 mg of azobisisobutyronitrile were thoroughly mixed, then ultrasonically treated for 20 minutes, nitrogen gas was passed for 10 minutes to remove dissolved oxygen, and then moved into a 60°C constant temperature water bath for thermal polymerization in a sealed state. After 24 hours, it was taken out and cooled to room temperature to obtain a colloidal polymer. After passing through a 200-mesh molecular sieve, it was extracted with 1:9 (v / v) acetic acid-methanol 200mL Soxhlet for 48h, then washed with methanol 200mL for 24h, and vacuum-dried to obtain a polymer are molecularly imprinted polymers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com