Phase-change thermoregulation textile fabric and method for preparing same

A phase change and fabric technology, which is applied in the processing of textile materials, liquid/gas/vapor textile material processing, textiles and papermaking, etc. The phase change process is completely reversible, intelligent and controllable temperature regulation, and cost-effective advantages are obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] At a mass concentration of 35% PEG ( =3000), the cross-linking agent dimethylol dihydroxyethylene urea (2D resin) and the catalyst MgCl 2 ·6H 2 O / citric acid (mass ratio is 5 / 1) reacts to generate PEG-2D cross-linked product as padding solution; the cotton sample to be treated adopts the process of padding→pre-baking→baking→washing→drying and after Finishing method, after the cotton fabric is treated with two dipping and two padding (the liquid squeeze rate is 90%), a crosslinking reaction occurs between the generated PEG-2D crosslinked product and the cellulose fiber, and a chemical bond is formed between the PEG and the cellulose, Pre-bake at 60°C for 7 minutes, bake at 140°C for 3 minutes, and then fully wash and dry to finally generate PEG-2D-Cell products, and obtain polyethylene glycol cross-linked deposition method phase change temperature-adjusting home textile fabrics. After testing, the sample The weight gain rate was 13.5%.

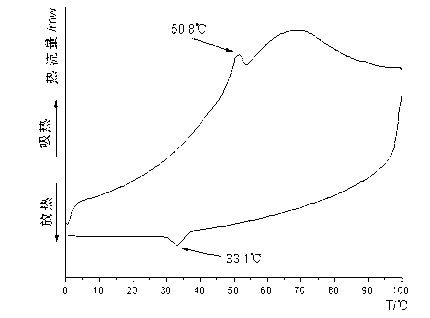

[0026] The thermal performanc...

Embodiment 2

[0029] At a mass concentration of 30% PEG ( =5000) solution, respectively add crosslinking agent 2D resin and catalyst MgCl according to the mass ratio of PEG to 85:15, 99.9:0.1 2 ·6H 2 O / citric acid (mass ratio is 5 / 1) reacts to generate PEG-2D cross-linked product as padding solution; the cotton sample to be treated adopts the process of padding→pre-baking→baking→washing→drying and after Finishing method, refer to the process conditions of Example 1, so that the PEG-2D crosslinked product is generated and then crosslinked with the cellulose fiber to form a chemical bond between PEG and cellulose, and finally generate the PEG-2D-Cell product, and obtain Polyethylene glycol crosslinking deposition method phase change temperature regulating home textile fabric, its weight gain rate is 14.2%.

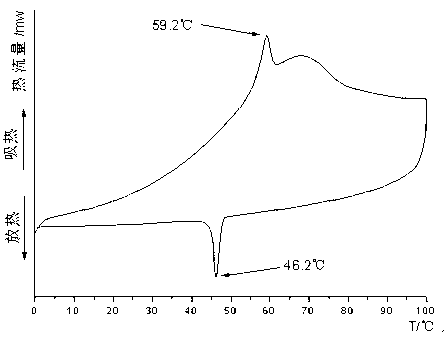

[0030] See attached figure 2 According to Example 1, the thermal properties of the fiber were analyzed with a DSC differential scanning calorimeter for the prepared sample, and the p...

Embodiment 3

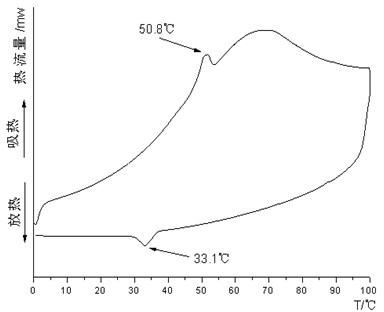

[0032] At a mass concentration of 45% PEG ( =1000) solution, respectively add crosslinking agent 2D resin and catalyst MgCl according to the mass ratio of PEG to 95:10, 99.9:0.1 2 ·6H 2O / citric acid (mass ratio is 5 / 1) reacts to generate PEG-2D cross-linked product, adopts padding→pre-baking→baking→washing→drying technology and finishing method, referring to the process conditions of Example 1 , so that the PEG-2D cross-linked product cross-links with the cellulose fiber to form a chemical bond between PEG and cellulose, and finally generates a PEG-2D-Cell product. The obtained polyethylene glycol cross-linked deposition method phase change modulation Wen Jiafang fabrics, the weight gain rate of 10.7%, the prepared samples according to Example 1 with DSC differential scanning calorimeter fiber thermal performance analysis, phase transition temperature in the range of 29.3 ~ 48.6 ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com