High-threshold voltage gallium nitride enhanced transistor structure and preparation method thereof

A high-threshold voltage, gallium nitride technology, used in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problem of poor performance of GaN integrated circuits, degradation of device electrical performance, and difficulty in accurately controlling the thickness of the AlGaN barrier layer in the gate region. and other problems, to achieve the effect of wide device operating voltage range, high source-drain saturation current density, and good controllability of the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

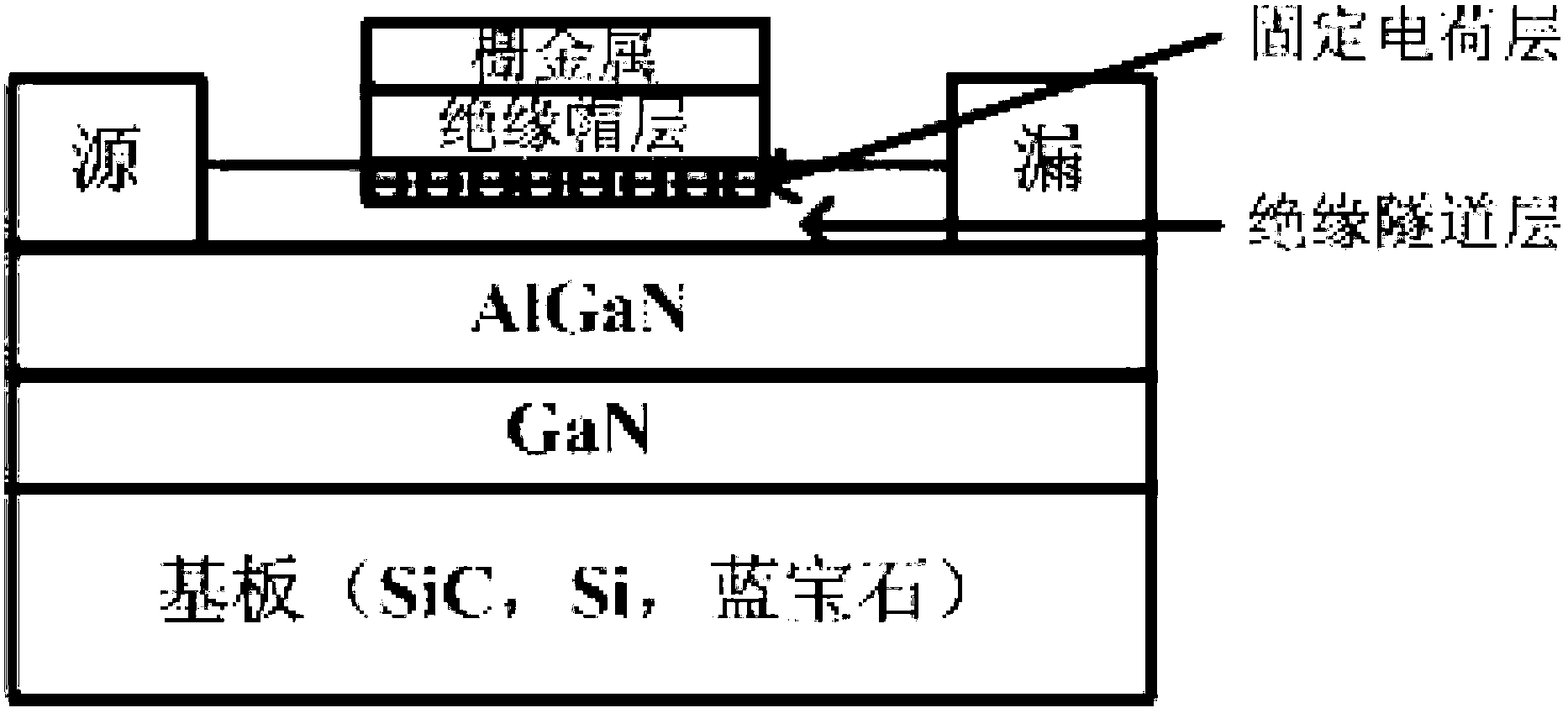

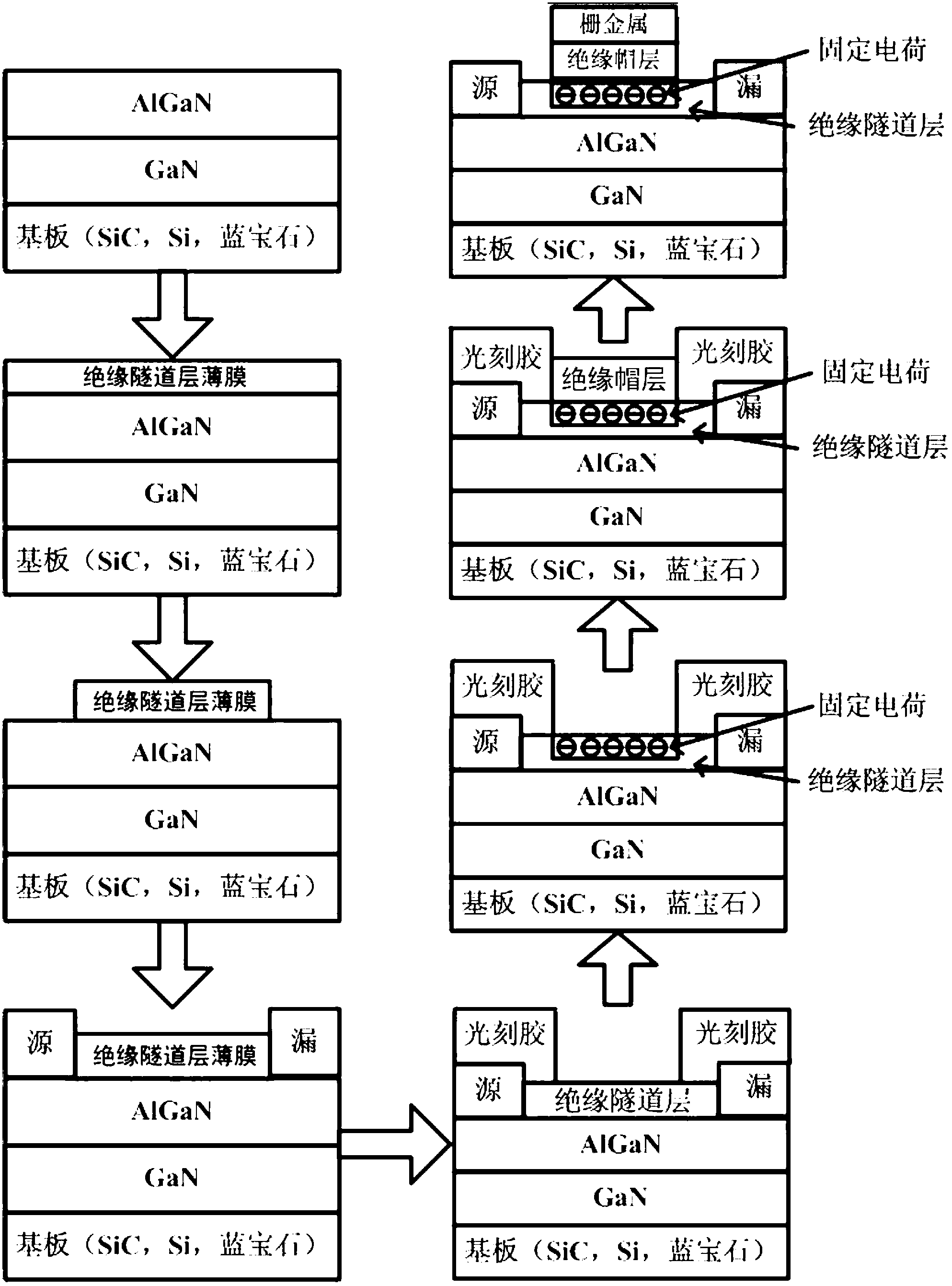

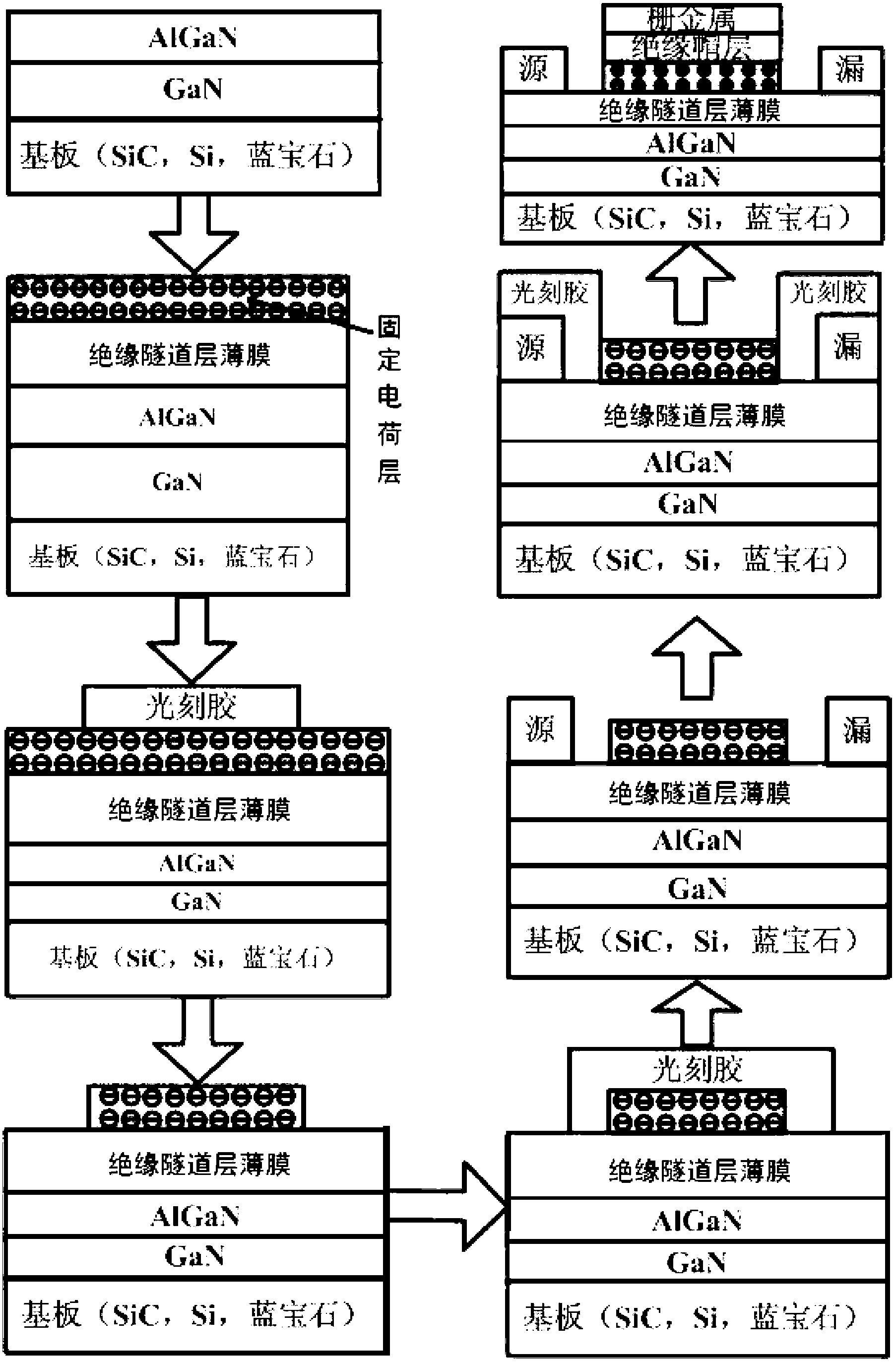

[0032] The schematic diagram of the basic structure of the enhanced GaN HEMT device of the present invention is as figure 1 As shown, it belongs to metal-insulator-semiconductor (MIS) field effect transistor. Compared with the common MIS structure GaN field effect transistor, the characteristics of the MIS structure GaN field effect transistor of the present invention are: the insulating gate dielectric includes an insulating cap layer, The three parts of the fixed negative charge layer and the insulating tunnel layer deplete the two-dimensional electron gas in the gate region by the charge of the fixed negative charge layer to achieve a threshold voltage greater than zero, and then further increase the threshold voltage of the device by introducing an insulating cap layer, thereby manufacturing GaN-enhanced high electron mobility transistors with higher thresholds, in which the insulating gate dielectric is mainly made of Al 2 o 3 , SiO 2 , HfO 2 , HfTiO, ZrO 2 、SiN x , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com