Production method for garlic tomato peas

A production method and a technology for eggplant peas, which are applied in the field of deep processing of beans, can solve problems such as difficulty in meeting people's suitable growth, and achieve the effect of crisp taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

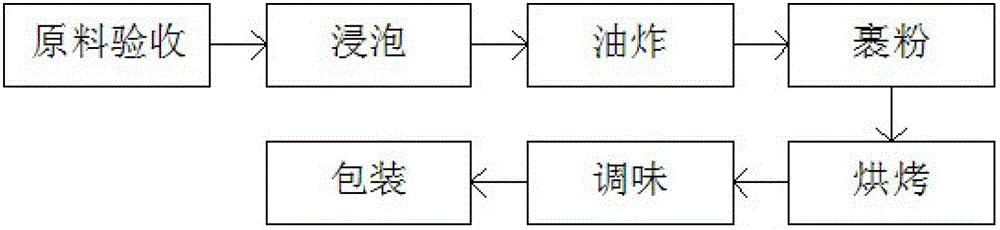

[0011] A kind of production method of pesto tomato pea according to the present invention, the raw material of described pesto tomato pea: pea, cornstarch, waxy cornstarch, white granulated sugar, salt, palm oil, pestotomato seasoning powder are tested and accepted The peas of acceptance are soaked in water for 2-5 hours, and the proportion of the peas accounted for is 74.2%, and the broad beans after soaking are fried, and then the 7.2% cornstarch, 6.3% waxy cornstarch, 0.04 Add 2.96% of paprika to palm oil and stir evenly and coat the surface of the fried peas to complete the powder coating step; bake the powder coated peas at a temperature of 100-130°C for about 2 hours, then mix with 4.7 % white granulated sugar, 2.1% salt, and 2.5% pesto tomato seasoning powder are put together and stirred evenly to complete the seasoning; finally, it is packaged in quantities.

[0012] Due to the application of the above-mentioned technical solution, the present invention has the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com