Efficient purification technology for ganoderma lucidum polysaccharide

A technology of Ganoderma lucidum polysaccharides and Ganoderma lucidum fruiting bodies, applied in the direction of membrane technology, chemical instruments and methods, ultrafiltration, etc., can solve the problems of unsuitability for large-scale industrial production, long concentration time, and low sample purity, and achieve short operation time, The effect of less solvent consumption and high purity of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

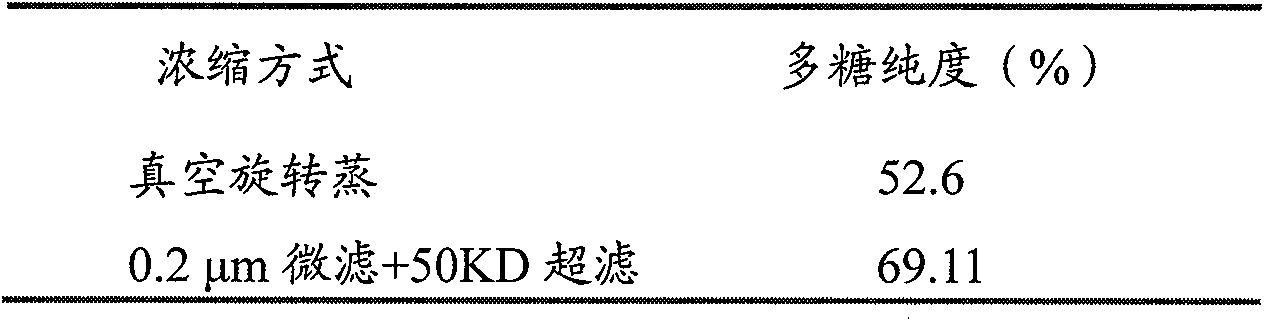

[0026] Example 1: Concentrating Ganoderma lucidum polysaccharide by vacuum rotary evaporation

[0027] ①Weigh 20 grams of Ganoderma lucidum fruiting body powder, add 560ML pure water and mix well, extract with an ultrasonic cell pulverizer (Zhejiang Ningbo Xinzhi Company; model: JY98-III ultrasonic cell pulverizer) at 680W for 17min, and remove the residue of Ganoderma lucidum by suction filtration;

[0028] ② Concentrate the filtrate to 140ML using a rotary evaporator;

[0029] ③ Slowly add 560ml of 95% ethanol to the concentrated solution while stirring, alcohol precipitation at 4°C for 12h, centrifuge at 4500rpm for 15min, discard the supernatant, wash the precipitate three times with absolute ethanol, acetone, ether, and freeze-dry Obtain Ganoderma lucidum crude polysaccharide powder, the crude polysaccharide purity is 52.6%.

Embodiment 2

[0030] Example 2: Concentration and separation of Ganoderma lucidum crude polysaccharide by ultrafiltration

[0031] ①Weigh 20 grams of Ganoderma lucidum fruiting body powder, add 560ML pure water and mix well, extract with an ultrasonic cell pulverizer (Zhejiang Ningbo Xinzhi Company; model: JY98-III ultrasonic cell pulverizer) at 680W for 17min, and remove the residue of Ganoderma lucidum by suction filtration;

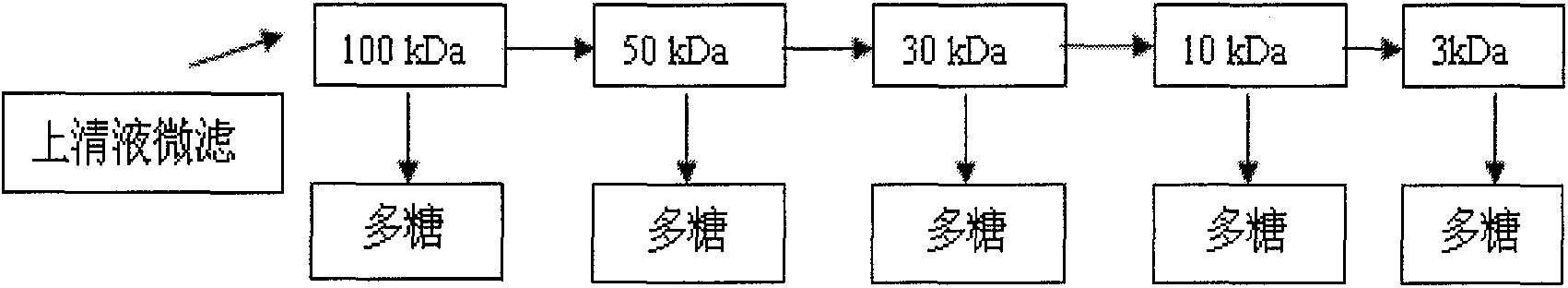

[0032] ② The extract is subjected to 0.2 μm microfiltration to remove impurities such as organic colloids and mechanical particles.

[0033] ③ The permeate after microfiltration is subjected to ultrafiltration treatment, and the feed liquid is transported to the surface of the membrane (50kDa, with a membrane area of 0.1m2) by a peristaltic pump for phase tangential flow, the filtrate is collected, and the retained liquid is returned to the liquid storage tank. When the feed liquid is concentrated to about a quarter of its volume, the ultrafiltration process ends....

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com