Benzene and homolog thereof-free waterborne polyurethane laser transfer coating and preparation method thereof

A water-based polyurethane and laser transfer technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as easy production of defective products, environmental pollution, efficiency and stability constraints, and achieve clear patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

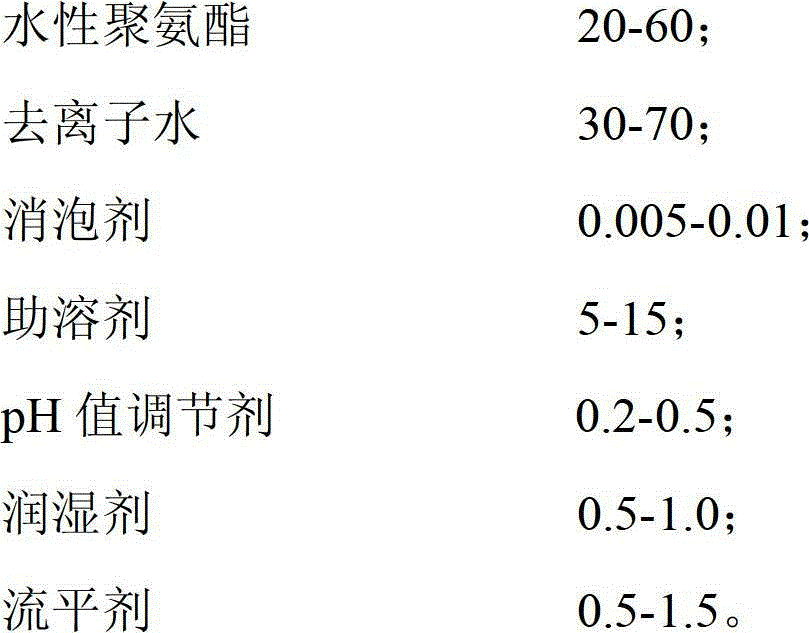

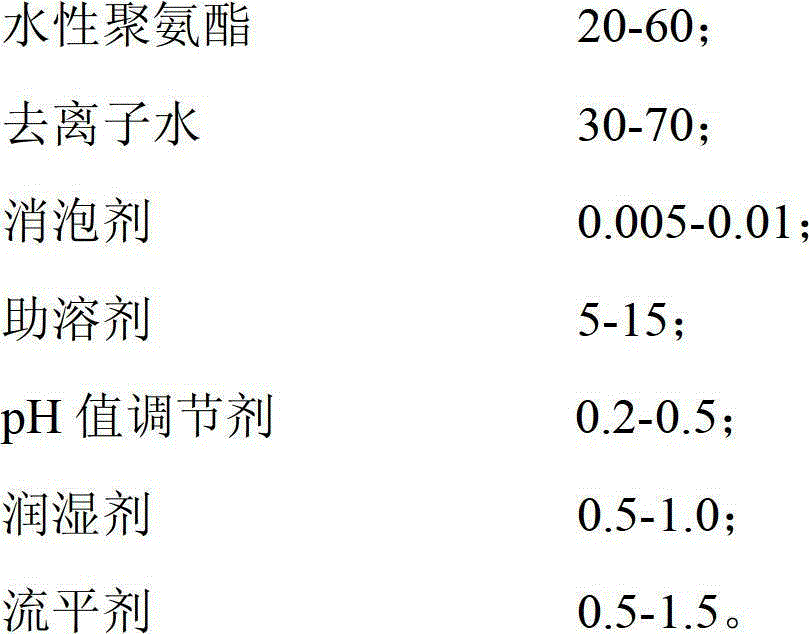

Method used

Image

Examples

Embodiment 1

[0047] 1. Preparation of water-based polyurethane resin:

[0048] Under the protection of dry nitrogen, 25kg of polybutylene adipate diol (hydroxyl value=56, Mn=2000) after vacuum dehydration and 25kg of isophorone diisocyanate (IPDI) were added to the reaction vessel. Stir the reaction at 85°C for 2h; reduce the temperature of the reaction system to 40°C, add 4.05kg of small molecule chain extender 1,4-butanediol, crosslinker trimethylolpropane (TMP) 0.28kg, solvent acetone 20kg, catalyst two 0.001kg of dibutyltin laurate (T-12) and 0.001kg of stannous octoate (T-9), stirred at 60℃ for 3h; after the reaction, add 4.2kg of sodium N-(2-aminoethyl) ethanesulfonate When the isocyanate group (-NCO) content in the reaction system no longer changes, it is lowered to room temperature, and 1.5kg of neutralizing agent triethylamine is added to neutralize the salt; then 70kg of water and 1.23kg of ethyl are added under high shear Diamine chain extension to obtain a transparent water-based...

Embodiment 2

[0055] 1. Preparation of water-based polyurethane resin:

[0056] Under the protection of dry nitrogen, 33.75kg of polybutylene adipate diol (hydroxyl value=112, Mn=1000) and 4,4'-dicyclohexylmethane diisocyanate (H12MDI) 88.5 after vacuum dehydration kg was added to the reaction vessel, stirred for 2h at 85℃; reduced the temperature of the reaction system to 40℃, added 12.15kg of small molecule chain extender 1,4-butanediol, 10.5kg of dimethylolpropionic acid, and crosslinking agent three Methylolpropane (TMP) 0.84kg, solvent acetone 20kg, catalyst dibutyltin dilaurate (T-12) 0.002kg and stannous octoate (T-9) 0.002kg, stirred and reacted at 60℃ for 3h, wait for the reaction system When the content of isocyanate group (-NCO) does not change, it is lowered to room temperature and 7.9kg of triethylamine is added to neutralize the salt; then 358kg of water and 10.5kg of isophoronediamine are added under high shear force to extend the chain to obtain Transparent water-based polyure...

Embodiment 3

[0064] 1. Preparation of water-based polyurethane resin:

[0065] Under the protection of dry nitrogen, 33.75kg of polyhexanediol adipate diol (hydroxyl value=112, Mn=1000) after vacuum dehydration and 56.7kg of hexamethylene diisocyanate (HDI) were added to the reaction vessel ,Stir the reaction at 85℃ for 2h; reduce the temperature of the reaction system to 40℃, add 12.15kg of small molecule chain extender 1,4-butanediol, 10.5kg of dimethylolpropionic acid, and crosslinker trimethylolpropane ( TMP) 0.84kg, solvent acetone 20kg, catalyst dibutyltin dilaurate (T-12) 0.002kg and stannous octoate (T-9) 0.002kg, stirred and reacted at 60°C for 3h, and the isocyanate group (- When the NCO content does not change anymore, lower to room temperature and add 7.8kg of triethylamine to neutralize the salt; then add 408kg of water and 4.2kg of diethylenetriamine under high shear to extend the chain to obtain a transparent waterborne polyurethane emulsion; The water-based polyurethane emuls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com