Indium tin oxide (ITO) target material and determination method for content of indium and tin during production process of ITO target material

A production process and measurement method technology, applied in the field of analysis, can solve problems such as inaccurate determination results of indium, inaccurate titration endpoints, and "tailing" of indicators, and achieve the effects of high accuracy, convenient operation, and simple reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] 1 reagent

[0047] 1.1 Hexamethylenetetramine: AR grade, solid.

[0048] 1.2 Potassium nitrate: AR grade, solid.

[0049] 1.3 Ammonium fluoride: AR grade, solid.

[0050] 1.4 EDTA standard solution: c(H 2 Y 2- )=0.02mol / L, weigh 15.04g of 99% EDTA, dissolve it in water, and set the volume to 2L, the content is close to 0.02mol / L.

[0051] 1.5 Zn 2+ Standard solution: c(Zn 2+ )=0.01mol / L, weigh 1.3106g99.8% zinc particles, dissolve with hydrochloric acid and set the volume to 2L, the content is 0.01mol / L.

[0052] 1.6 In 3+ Standard solution: c(In 3+ )=0.01g / ml, In 3+ Standard solution: Weigh 1g of indium and dissolve it with hydrochloric acid to 100ml, c(In 3+ )=0.01g / ml.

[0053] 1.7 Xylenol orange indicator: 2g / L.

[0054] 2 Titration of indium tin content

[0055] Dilute the sample with unknown content (indium tin hydroxide powder or indium tin oxide target) through microwave digestion to prepare indium tin solution, dilute it with 5% dilute hydrochloric...

example 1

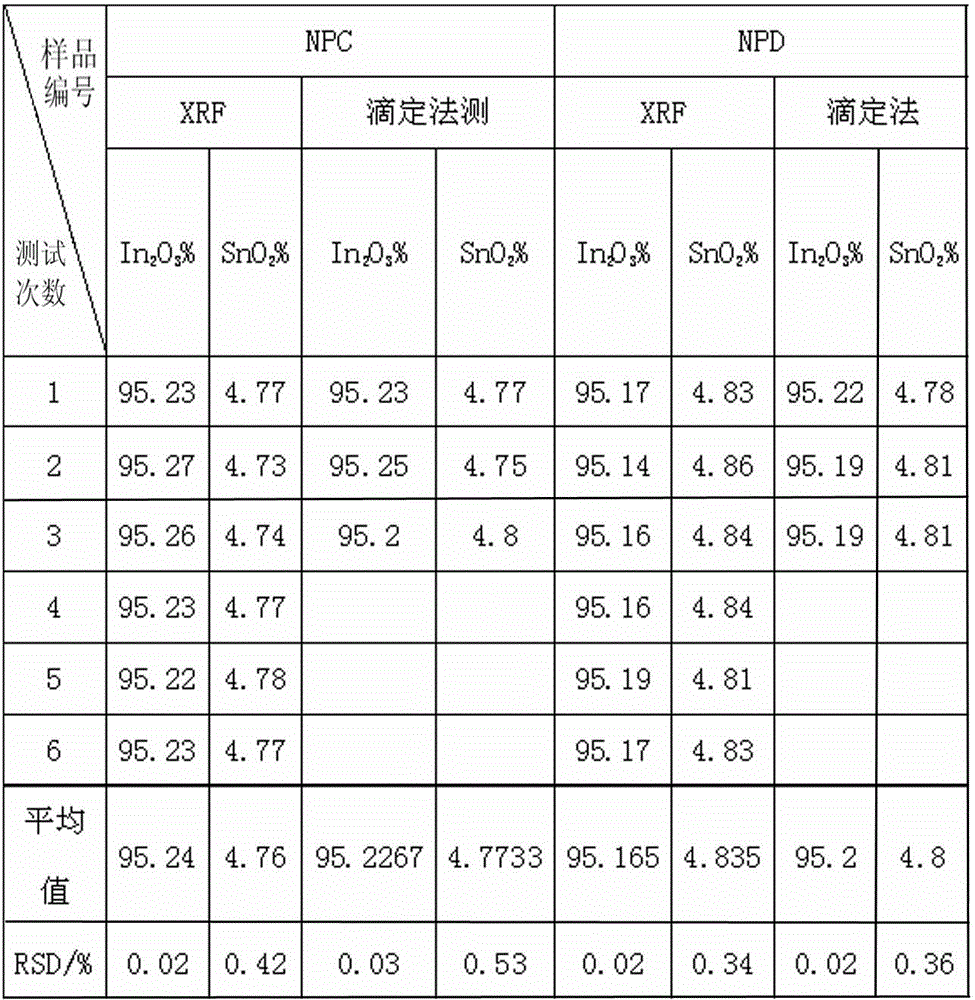

[0068] Example 1: Accurately weigh 1.2g of indium tin oxide powder with sample numbers NPC and NPD, moisten with a little water, add 20ml of concentrated hydrochloric acid for microwave digestion, dilute the digested sample to 100ml, and operate according to the above test steps. The obtained test results are compared with the XRF test results as shown in Table 1, in which the indium and tin contents are calculated in the form of indium oxide and tin oxide, and the titration method and XRF test experimental data are shown in figure 1

example 2

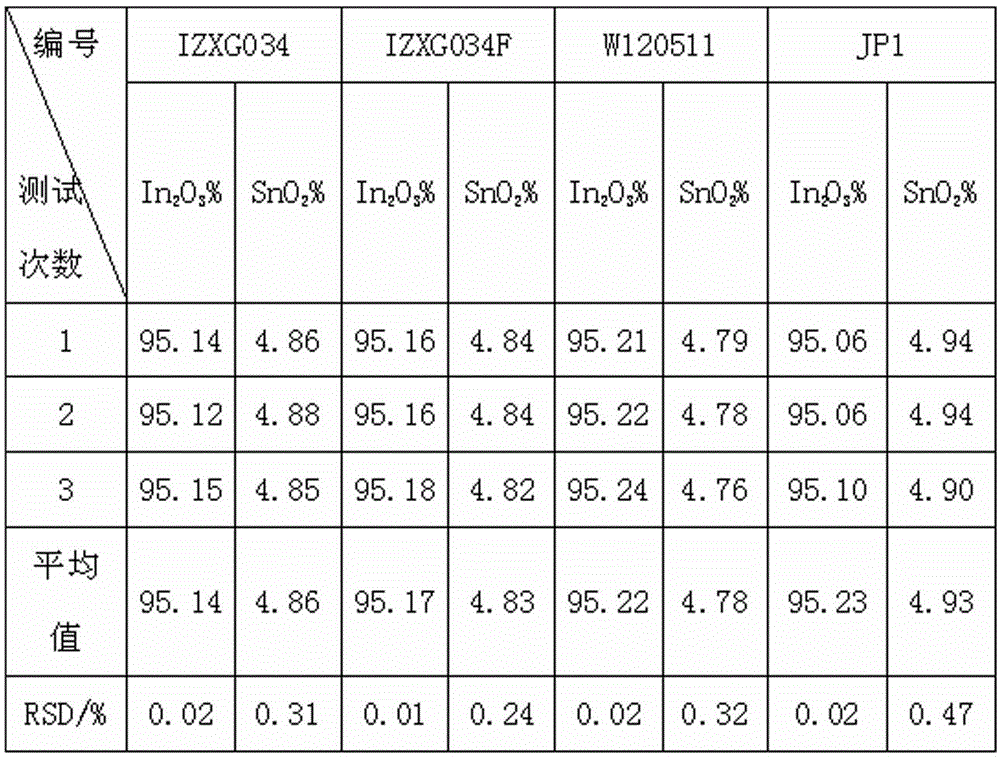

[0069] Example 2: The number IZXG034 indium tin solution with unknown content is diluted to 100ml with 5% dilute hydrochloric acid; the number IZXG034F slurry is concentrated, heated and dissolved with concentrated hydrochloric acid, diluted to 100ml, and the indium content is about 10g / L; Take 1.5g of the hydroxide with the serial number W120511, dry it to remove moisture, add 20ml concentrated hydrochloric acid, heat and dissolve, and set the volume to 100ml; Grind the JP1 target until it passes through a 100-mesh sieve, and dry the sieved powder to remove moisture Finally, weigh 1.0 g and moisten it with a small amount of water, add 20 ml of concentrated hydrochloric acid for microwave digestion. According to the above test steps, the obtained test results are shown in figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com