Preparation method of oxide or meta-coated nickel ultrafine powder

A technology of metal coating and ultrafine powder, which is applied in the direction of coating, etc., can solve the problems of high surface energy, easy agglomeration, easy oxidation, etc., and achieve the effect of simple preparation process, high oxidation resistance and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

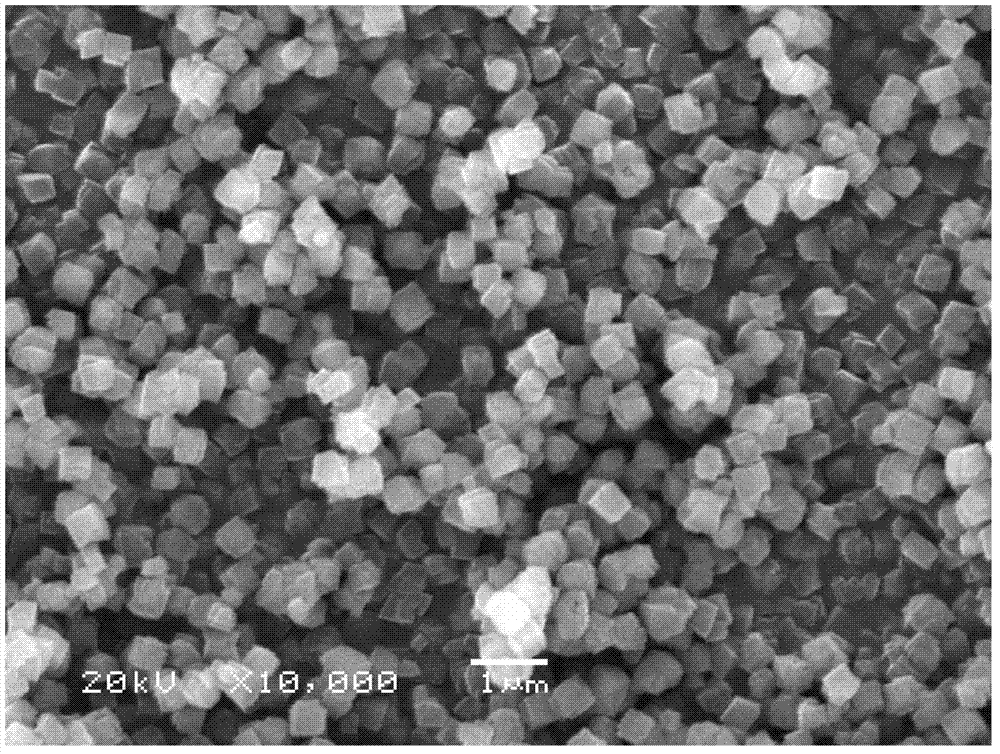

Embodiment 1

[0034] First weigh 5 moles of nickel sulfate hexahydrate and dissolve it in 5L deionized water to make a 1mol / L solution, add 1.2L of absolute ethanol, stir to mix evenly, then weigh 5 moles of ammonium oxalate and dissolve it in Prepare 0.25 mol / L solution in 20 L of deionized water, add 4 L of absolute ethanol, stir to mix evenly, and adjust its pH value to 6 with hydrochloric acid (37.5 wt % concentrated hydrochloric acid). The ammonium oxalate solution was added to the nickel sulfate aqueous solution at a rate of 0.5 L / min, stirred at a rate of 300 rpm for 30 minutes, and the reaction temperature was 25° C. to obtain a single precursor solution.

[0035] Then, weigh 5 moles of magnesium chloride and dissolve it in 5L deionized water to prepare a 1mol / L solution, then weigh 5 moles of ammonium oxalate and dissolve it in 5L deionized water to prepare a 1mol / L solution. / L magnesium chloride solution and 1mol / L ammonium oxalate solution were simultaneously added to a single p...

Embodiment 2

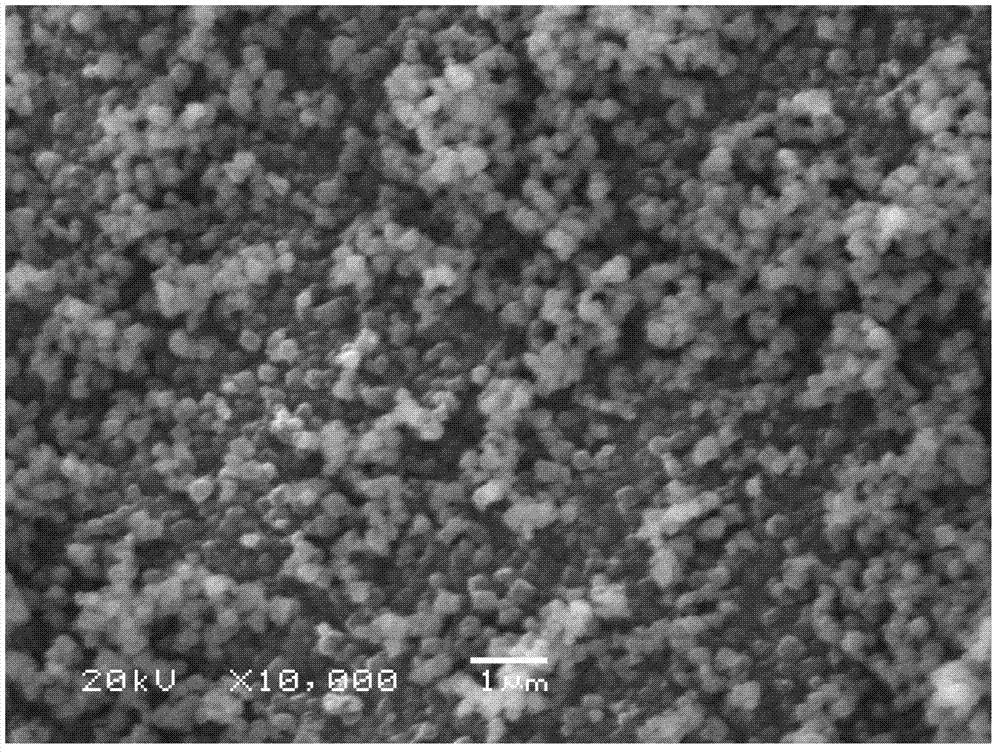

[0039] First weigh 7.5 moles of nickel sulfate hexahydrate and dissolve it in 5L deionized water to form a 1.5mol / L solution, add 1.2L of absolute ethanol, stir to mix evenly, then weigh 7.5 moles of ammonium oxalate and dissolve In 20L of deionized water, prepare a solution of 0.375mol / L, add 4L of absolute ethanol, stir to mix evenly, adjust the pH to 6 with hydrochloric acid, add the ammonium oxalate solution to nickel sulfate at a rate of 0.5L / min The solution was stirred at a speed of 300 rpm for 30 minutes, and the reaction temperature was 25° C. to prepare a single precursor solution.

[0040] Then, weigh 7.5 moles of magnesium chloride and dissolve it in 7.5L deionized water to prepare a 1mol / L solution, then weigh 7.5 moles of ammonium oxalate and dissolve it in 7.5L deionized water to prepare a 1mol / L solution. 1mol / L nickel sulfate solution and 1mol / L ammonium oxalate solution were simultaneously added to a single precursor solution at a speed of 0.5L / min, and stirr...

Embodiment 3

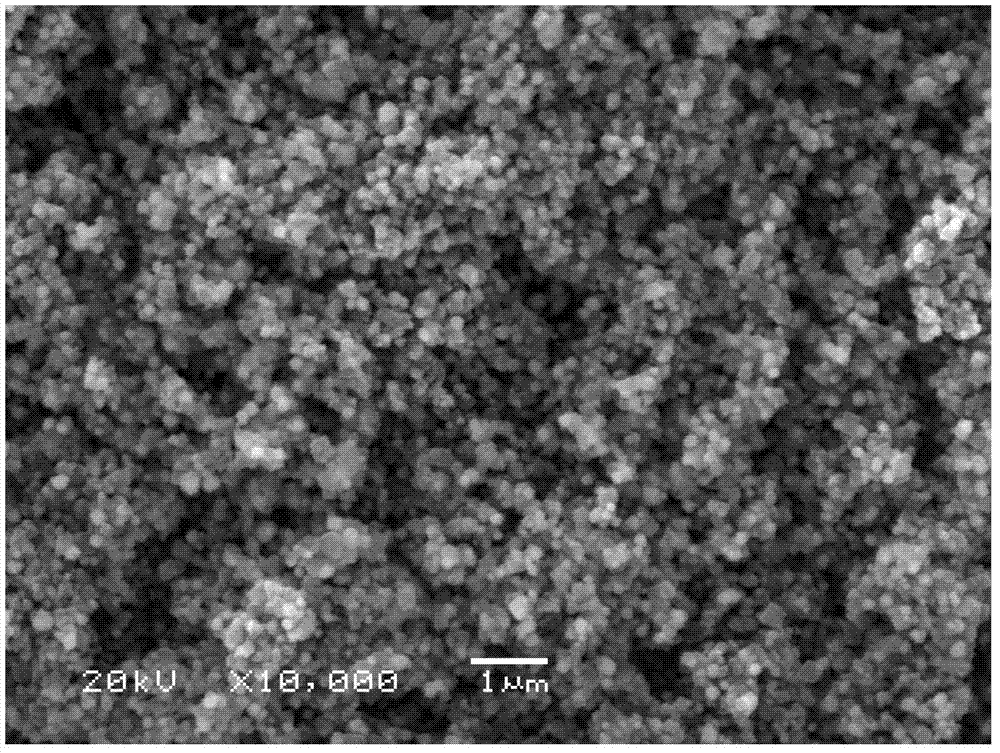

[0043] First weigh 5 moles of nickel sulfate hexahydrate and dissolve it in 5L deionized water to make a 1mol / L solution, add 1.2L of absolute ethanol, stir to mix evenly, then weigh 5 moles of ammonium oxalate and dissolve it in Prepare a 0.25mol / L solution in 20L of deionized water, add 4L of absolute ethanol, stir to mix evenly, adjust the pH value to 6 with hydrochloric acid, add the ammonium oxalate solution to nickel sulfate at a rate of 0.5L / min The solution was stirred at a speed of 300 rpm for 30 minutes at a reaction temperature of 25° C. to prepare a single precursor solution.

[0044] Then, weigh 2.5 moles of magnesium chloride and be dissolved in 5L deionized water to prepare a 0.5mol / L solution, then weigh 2.5 moles of ammonium oxalate and dissolve in 5L deionized water to prepare a 0.5mol / L solution. The nickel sulfate solution and the ammonium oxalate solution were simultaneously added to a single precursor solution at a speed of 0.5 L / min, and stirred at a spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com