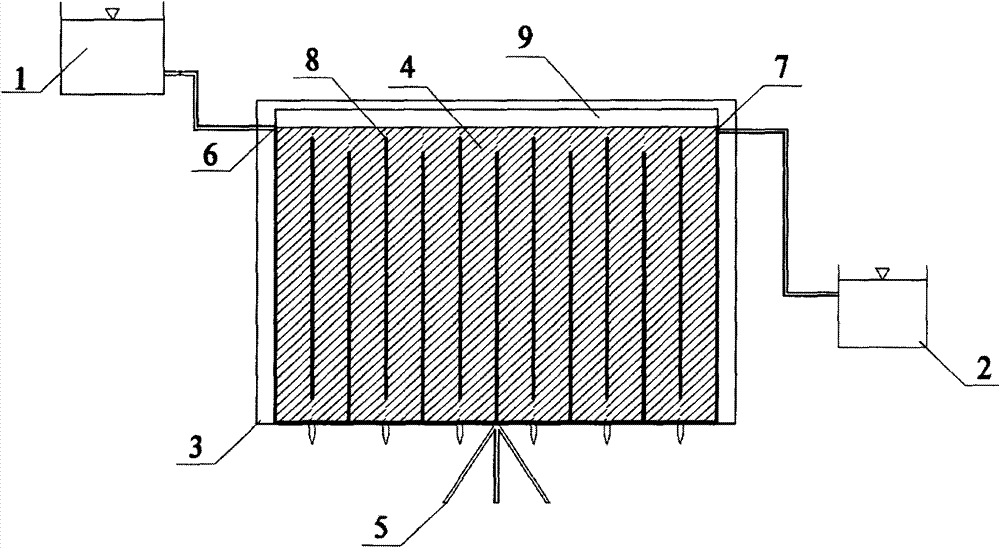

Flat-plate solar photocatalysis water purifier for collected rainwater and drinking water

A solar and flat-panel technology, applied in the direction of light water/sewage treatment, etc., can solve the problem of heavy metals, achieve the effects of avoiding frostbite, convenient sampling and monitoring of water quality, and good photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

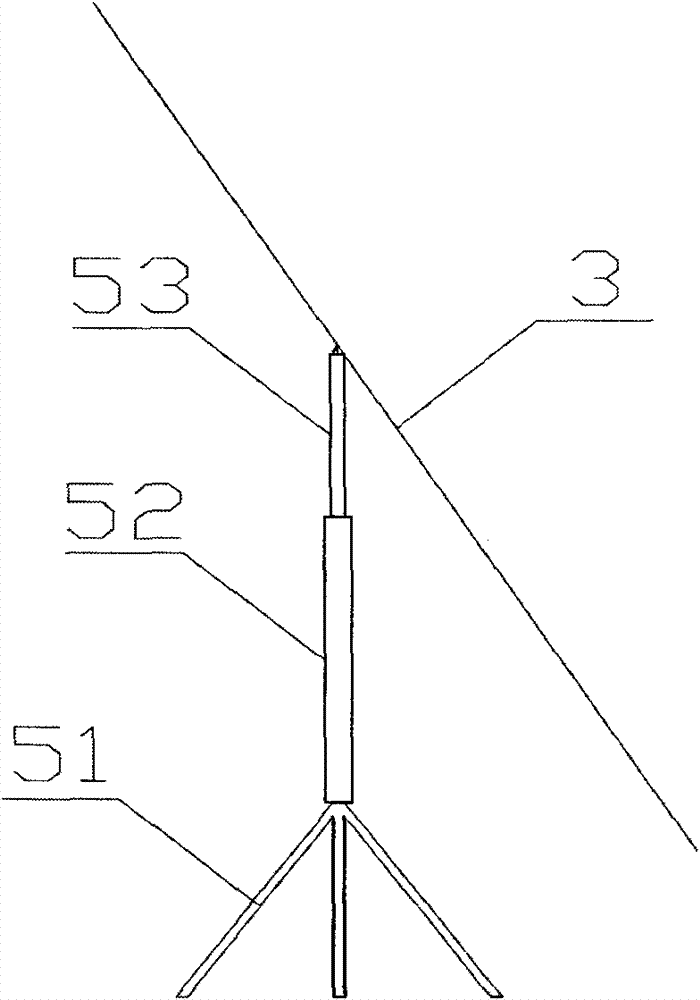

Method used

Image

Examples

Embodiment 1

[0032] Example 1 First, add ammonia water dropwise in distilled water to make the pH value 6; then add tetra-n-butyl titanate under magnetic stirring, stir until white precipitate is completely produced, and then add H with a mass concentration of 30% dropwise. 2 o 2 , and after stirring for 30 minutes, a uniformly mixed yellow peroxotitanic acid sol was obtained; secondly, the clean and dry geotextile was ultrasonically oscillated in the peroxotitanic acid sol, and after 5 minutes, it was sealed and heated to 30°C, and kept warm 6h; Finally, take out the geotextile, place it in a ventilated place for 3 days, and get TiO after repeated washing for 3 to 4 times. 2 / Geotextile supported photocatalyst.

[0033] Wherein the molar ratio of tetra-n-butyl phthalate, distilled water and hydrogen peroxide is 1:30:1.

Embodiment 2

[0034] Example 2 First, add ammonia water dropwise in distilled water to make the pH value 12; then add tetra-n-butyl titanate under magnetic stirring, stir until white precipitate is completely produced, and then add H with a mass concentration of 30% dropwise. 2 o 2 , and after stirring for 180 minutes, a uniformly mixed yellow peroxotitanic acid sol was obtained; secondly, the clean and dry geotextile was ultrasonically oscillated in the peroxotitanic acid sol, and after 30 minutes, it was sealed and heated to 95°C, and kept warm 36h; Finally, take out the geotextile, place it in a ventilated place for 7 days, and get TiO after repeated washing for 3-4 times. 2 / Geotextile supported photocatalyst.

[0035] Wherein the molar ratio of tetra-n-butyl phthalate, distilled water and hydrogen peroxide is 1:151:12.

Embodiment 3

[0036] Example 3 First, ammonia water was added dropwise in distilled water to make the pH value 9; then tetra-n-butyl titanate was added under magnetic stirring, and stirred until a white precipitate was completely formed, and then 30% H 2 o 2, and after stirring for 150 minutes, a uniformly mixed yellow peroxotitanic acid sol was obtained; secondly, the clean and dry geotextile was ultrasonically oscillated in the peroxotitanic acid sol, and after 20 minutes, it was sealed and heated to 65°C, and kept warm 21h; Finally, take out the geotextile, place it in a ventilated place for 5 days, and get TiO after repeated washing for 3 to 4 times. 2 / Geotextile supported photocatalyst.

[0037] Wherein the molar ratio of tetra-n-butyl phthalate, distilled water and hydrogen peroxide is 1:90:6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com