Synchronous deep purification technology for various pollutants in industrial flue gas

A technology for deep purification and industrial flue gas, which is applied in the fields of air quality improvement, chemical instruments and methods, and separation of dispersed particles. Low operating cost, good environmental benefits, and high oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

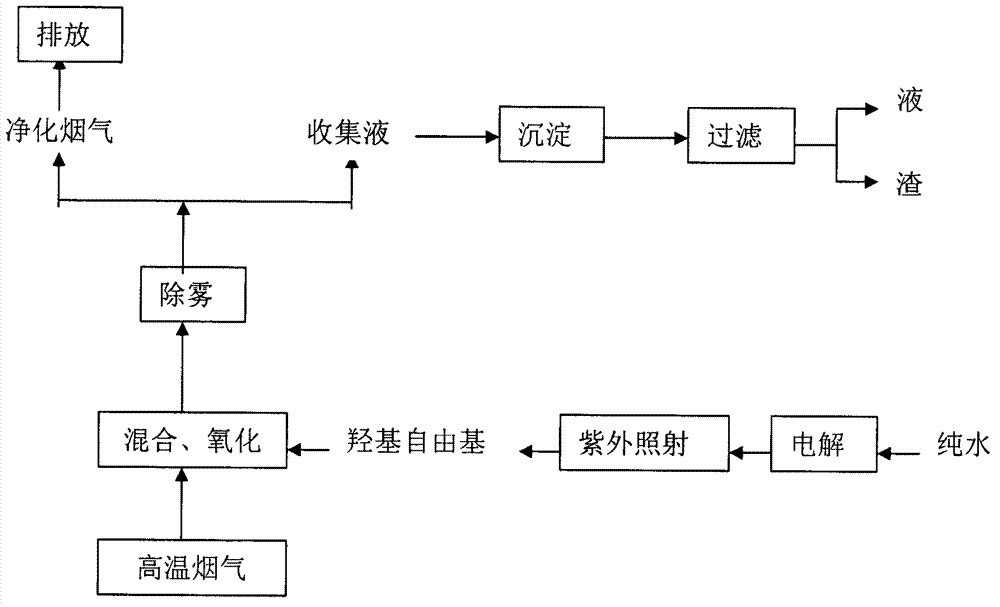

Method used

Image

Examples

Embodiment 1

[0021] The content of each pollutant in the simulated flue gas: SO x : 448.53mg / m 3 , NO x : 369.81mg / m 3 、Hg: 0.862mg / m 3 , VOC (calculated as toluene): 76.55mg / m 3 , Dioxins: 5.238ng I-TEQ / Nm 3 , PM2.5: 3874.34mg / m 3 , the inlet flow rate of the flue gas purification system is set at 6000-8000m 3 / h, flue gas temperature: 140~160℃, treatment time 1~3h.

[0022] The electrolysis of pure water is carried out in a 25L sealed electrolytic cell, the cathode material is aluminum, the anode material is platinum, the voltage is 100v, and 2 254nm ultraviolet lamps are used, and the light intensity is 9200μW / cm 2 . The electrolyzer is connected to the Venturi injection pipe, and its throat position faces the direction of the flue gas, and a three-stage Venturi injection pipe is installed along with the flue gas flow. The oxidized flue gas enters the electrostatic defogging system, and the pollutant content in the purified flue gas is measured as SO x : 6.37mg / m 3 , NO x : ...

Embodiment 2

[0025] The content of each pollutant in the simulated flue gas: SO x : 1500mg / m 3 , NO x : 387.26mg / m 3 、Hg: 0.483mg / m 3 , VOC (calculated as toluene): 46.67mg / m 3 , Dioxins: 2.135ng I-TEQ / Nm 3 , Particles: 3248.83mg / m 3 , the flue gas flow rate is set to 6000 ~ 8000m 3 / h, flue gas temperature: 140~160℃, treatment time 1~3h.

[0026] The electrolysis of pure water is carried out in a 25L sealed electrolytic cell, the cathode material is stainless steel, the anode material is lead, the voltage is 50v, and 2 254nm ultraviolet lamps are used, and the light intensity is 9200μW / cm 2 . The electrolyzer is connected to the Venturi injection pipe, and its throat position faces the direction of the flue gas, and a first-stage Venturi injection pipe is installed along with the direction of the flue gas. The oxidized flue gas enters the baffle defogging system, and the pollutant content in the purified flue gas is measured as SO x : 90.48mg / m 3 , NO x : 6.25mg / m 3 , Hg: 5.4...

Embodiment 3

[0029] The content of each pollutant in the simulated flue gas: SO x : 188.23mg / m 3 , NO x : 318.26mg / m 3 、Hg: 0.318mg / m 3 , VOC (calculated as toluene): 20.58mg / m 3 , Dioxins: 1.311ng I-TEQ / Nm 3, particulate matter: 2984.36mg / m 3 , the flue gas flow rate is set to 4000 ~ 6000m 3 / h, flue gas temperature: 90°C, treatment time 1-3h.

[0030] The electrolysis of pure water is carried out in a 25L sealed electrolytic cell, the cathode material is aluminum, the anode material is graphite, the voltage is 10v, and 2 254nm ultraviolet lamps are used, and the light intensity is 9200μW / cm 2 . The electrolyzer is connected to a gas mixer, and a 2-stage gas mixer is set along with the flue gas flow. The oxidized flue gas enters the cyclone demisting system, and the pollutant content in the purified flue gas is measured as SO x : 18.69mg / m 3 , NO x : 20.14mg / m 3 、Hg: 0.052mg / m 3 , VOC (calculated as toluene): 1.86mg / m 3 , Dioxins: 0.158ng I-TEQ / Nm 3 , Particles: 10.24mg / m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com