Preparation method of composite type inorganic polymeric flocculating agent and application thereof

An inorganic polymer and flocculant technology, applied in the preparation and application of flocculants, the preparation and application of composite inorganic polymer flocculants, can solve the problems of secondary pollution, high chroma of effluent, poor stability, etc., and achieve Wide application range, good flocculation effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

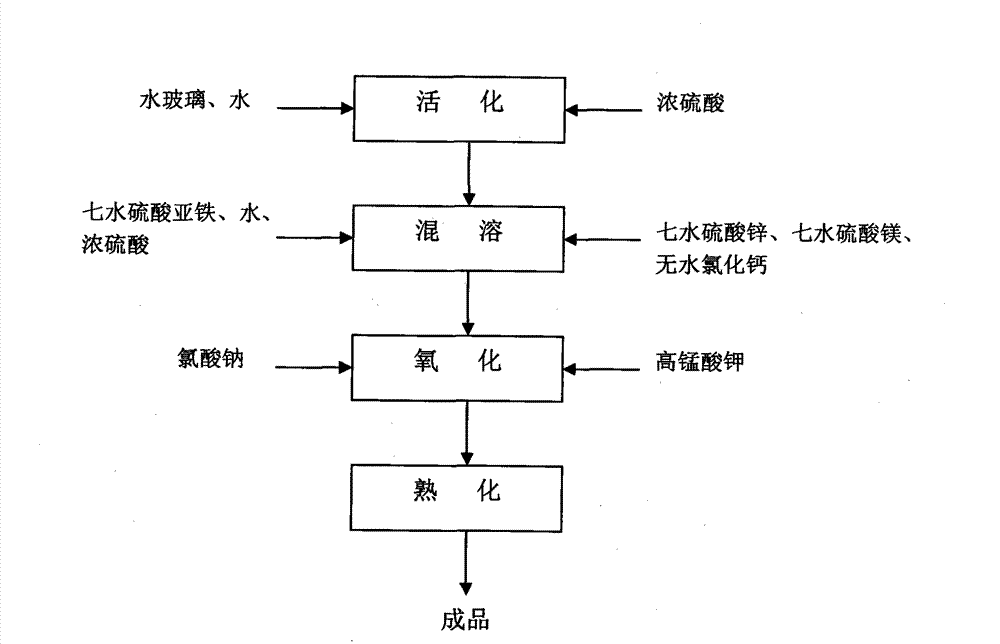

Method used

Image

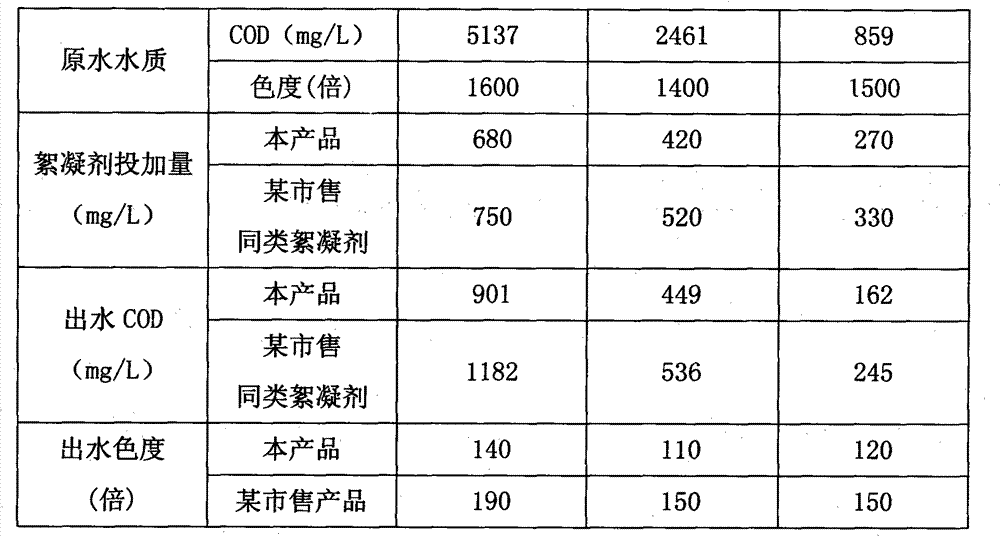

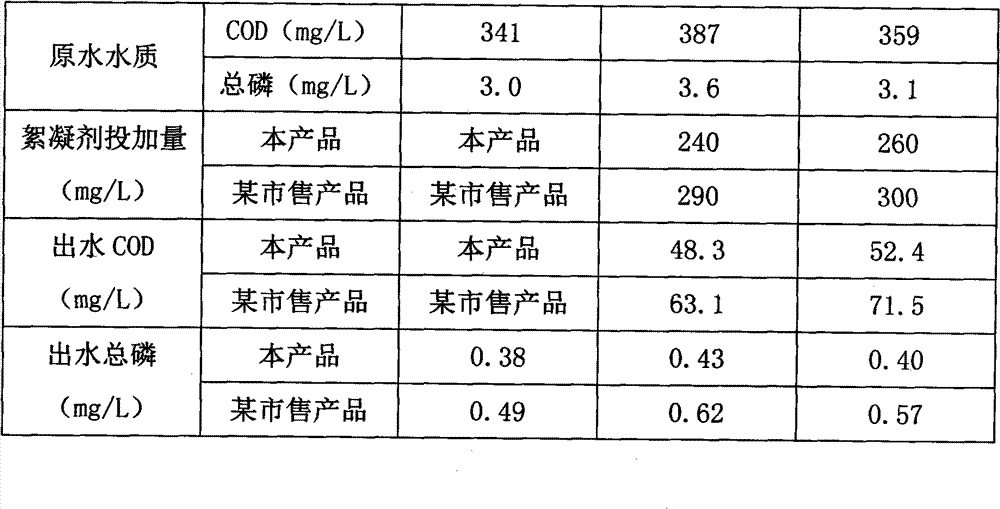

Examples

Embodiment 1

[0026] Dilute 5.52 kg of water glass (the mass fraction of sodium silicate is 57%) with 20 kg of water and add it to the reaction kettle, add 3.8 kg of concentrated sulfuric acid, stir at room temperature for 2 hours, and perform activated polymerization at a stirring speed of 100-120 rpm to obtain Semi-finished product A; Add 116 kg of ferrous sulfate heptahydrate, 34.1 kg of water, 3.6 kg of concentrated sulfuric acid, 3.0 kg of zinc sulfate heptahydrate, 4.0 kg of magnesium sulfate heptahydrate, and 3.0 kg of anhydrous calcium chloride in the semi-finished product A. The temperature is raised to 40°C, stirring to dissolve the above-mentioned substances, the stirring speed is 120-150 rpm, and the semi-finished product B is obtained; 6.2 kg of sodium chlorate and 0.6 kg of potassium permanganate are slowly added dropwise to the semi-finished product B at the same time, and the reaction kettle Stir until the sodium chlorate and potassium permanganate are added dropwise with the...

Embodiment 2

[0028] Dilute 3.46 kg of water glass (the mass fraction of sodium silicate is 57%) with 15 kg of water and add it to the reaction kettle, add 3.5 kg of concentrated sulfuric acid, stir at room temperature for 2 hours, and perform activated polymerization at a stirring speed of 100-120 rpm to obtain Semi-finished product A; Add 130 kg of ferrous sulfate heptahydrate, 26.1 kg of water, 6.3 kg of concentrated sulfuric acid, 2.0 kg of zinc sulfate heptahydrate, 3.0 kg of magnesium sulfate heptahydrate, and 2.0 kg of anhydrous calcium chloride in the semi-finished product A. The temperature is raised to 40°C, stirring to dissolve the above-mentioned substances, the stirring speed is 120-150 rpm, and the semi-finished product B is obtained; 7.6 kg of sodium chlorate and 0.84 kg of potassium permanganate are slowly added dropwise to the semi-finished product B at the same time. Stir and oxidize under the condition of raising the temperature to 65°C until the sodium chlorate and potass...

Embodiment 3

[0030]Dilute 4.62 kg of water glass (the mass fraction of sodium silicate is 57%) with 20 kg of water and add it to the reaction kettle, add 4.0 catties of concentrated sulfuric acid, stir at room temperature for 2 hours, and perform activated polymerization at a stirring speed of 100-120 rpm to obtain Semi-finished product A; Add 122 kg of ferrous sulfate heptahydrate, 48 kg of water, 5.0 kg of concentrated sulfuric acid, 2.6 kg of zinc sulfate heptahydrate, 3.4 kg of magnesium sulfate heptahydrate, and 2.4 kg of anhydrous calcium chloride in the semi-finished product A. The temperature is raised to 40°C, stirring to dissolve the above-mentioned substances, the stirring speed is 120-150 rpm, and the semi-finished product B is obtained; 7.1 kg of sodium chlorate and 0.77 kg of potassium permanganate are slowly added dropwise to the semi-finished product B at the same time. Stir and oxidize with the temperature raised to 55°C until the sodium chlorate and potassium permanganate are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com