Plastic wood profile with abrasion resistance, scratch resistance, fouling resistance and weather resistance and preparation method thereof

A profile and wood-plastic technology, which is applied in the field of wood-plastic profiles, can solve the problems of wear, pollution and aging, metal sheet or metal foil falling off, high cost of plastic-wood profiles, and achieve high pollution resistance and long service life , high weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

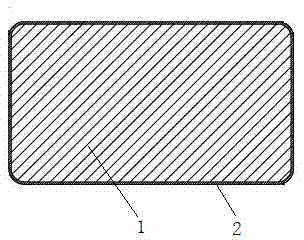

[0038] Such as figure 1 As shown, the plastic wood profile in this embodiment is a chamfered rectangle, including a core material 1, and the upper, lower, left, and right walls of the core material 1 are coated with wear-resistant, scratch-resistant, stain-resistant and high-weather-resistant plastic in a co-extruded manner. protective layer 2.

[0039] The material of the protective layer consists of the following components by weight percentage:

[0040] 10% HDPE (low pressure polyethylene),

[0041] 50% PP (polypropylene),

[0042] 10% EAA (ethylene-acrylic acid copolymer),

[0043] 10% nano ZnO,

[0044] 16.7% talcum powder,

[0045] 0.5% antioxidant 1010,

[0046] 0.5% anti-ultraviolet agent - 2,2,6,6-tetramethyl-4-piperidinol stearate.

[0047] 1.3% toner - iron oxide yellow,

[0048] 1.0% zinc borate.

[0049] The preparation method of the plastic wood profile of this embodiment is:

[0050] (1) Prepare the covering fabric and the core material separately:

...

Embodiment 2

[0058] The structure of the wood-plastic profiles in this embodiment is the same as that in Embodiment 1.

[0059]The material of the protective layer of this embodiment consists of the following components by weight percentage:

[0060] 40% HDPE (low pressure polyethylene),

[0061] 10% PP (polypropylene),

[0062] 20% EAA (ethylene-acrylic acid copolymer),

[0063] 20% nano ZnO,

[0064] 8.3% filler calcium carbonate,

[0065] 0.3% mixture of Antioxidant 1010 and Antioxidant 168,

[0066] 0.3% anti-UV agent 2-(2'-hydroxy-5'-methylphenyl)benzotriazole,

[0067] 0.5% carbon black,

[0068] 0.6% antifungal agent chlorothalonil.

[0069] The preparation method of the plastic wood profile of this embodiment is:

[0070] (1) Prepare the covering fabric and the core material separately:

[0071] The preparation method of the coated fabric as the protective layer is: after surface activation treatment of nano-zinc oxide powder and inorganic powder filler, mixed with low-pre...

Embodiment 3

[0078] The structure of the wood-plastic profiles in this embodiment is the same as that in Embodiment 1.

[0079] The material of the protective layer of this embodiment consists of the following components by weight percentage:

[0080] 20% HDPE (low pressure polyethylene),

[0081] 20% PP (polypropylene),

[0082] 40% EAA (ethylene-acrylic acid copolymer),

[0083] 2% nano ZnO,

[0084] 16.7% filler kaolin,

[0085] 0.2% antioxidant 1010,

[0086] 0.2% anti-ultraviolet agent UV531,

[0087] 0.4% iron oxide yellow,

[0088] 0.5% folpet.

[0089] The preparation method of this example is the same as that of Example 1, and will not be repeated here.

[0090] The wood-plastic profiles prepared in this embodiment have been tested and have the following excellent properties:

[0091] Binding force: ASTM D7032 freeze-thaw test 40 cycles without peeling, peeling. Wear resistance: ASTM D4060 standard test 1000 rpm wear resistance 30mg; aging resistance: SO4892-2: 2006 stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com