Compound decarburization solution for removing carbon dioxide in natural gas and preparation method thereof

A carbon dioxide and natural gas technology, applied in chemical instruments and methods, separation methods, carbon compounds, etc., can solve the problems of expensive decarbonization solution, low absorption load, long delivery cycle, etc., to reduce solution degradation and stabilizer failure risk, reduced oxygen content, and the effect of high absorption load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the compound decarburization solution for removing carbon dioxide in natural gas of the present invention is characterized in that, comprises the following steps:

[0042] (a) Before the preparation, feed nitrogen into the reactor to exhaust the air in the reactor;

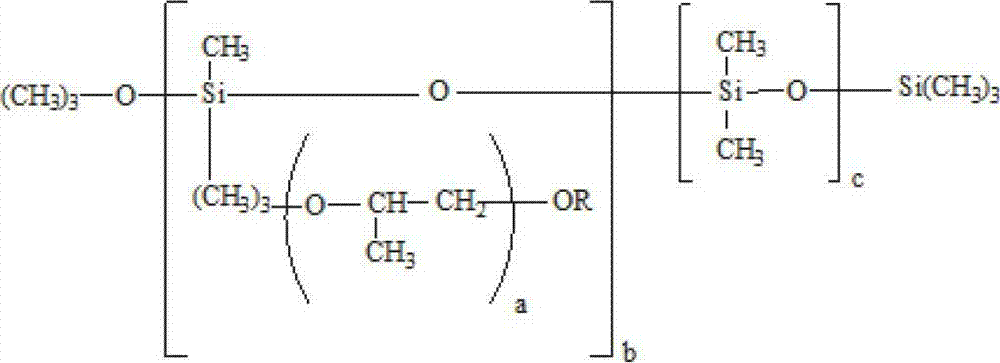

[0043] (b) Set the temperature of the reactor at 20-40° C., add a proportional amount of N-methyldiethanolamine and water into the reactor, and stir the two evenly;

[0044](c) sequentially add proportional amount of activator, corrosion inhibitor, stabilizer and defoamer in the reactor;

[0045] (d) continue to stir the mixed solution until it is evenly discharged to obtain the product;

[0046] (e) During the preparation process, nitrogen needs to be used for protection.

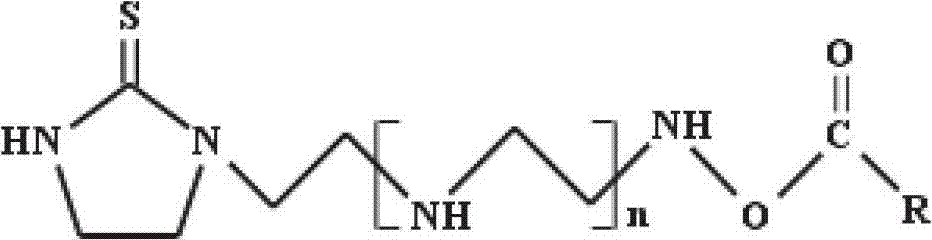

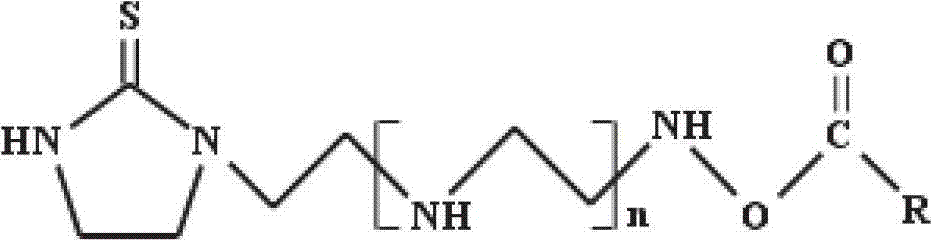

[0047] The present invention removes the preparation method of the composite decarburization solution of carbon dioxide in natural gas, wherein, the activator is the mixture of polyethylene polyamine and diis...

Embodiment 1

[0073] A natural gas processing plant processes 960,000 cubic meters of natural gas per day, operating pressure is 5.0 MPa, and raw gas components (mol): methane 67.0%, ethane 1.2%, propane 0.9%, carbon dioxide 24.2%, nitrogen 6.7%; the invention removes The preparation method of the composite decarburization solution of carbon dioxide in natural gas:

[0074] a. Before the preparation, feed nitrogen into the reactor to exhaust the air in the reactor;

[0075] b. Set the temperature of the reactor to 35°C, add 43.0% by weight of N-methyldiethanolamine and 52.75% of deionized water into the reactor, and stir the two evenly;

[0076] c. Adding 4% activator by weight in sequence in the reaction kettle, the mixture of triethylenetetramine (TETA) and diisopropanolamine is used as the activator in this embodiment, and the activator is 60.0% by weight Triethylenetetramine mixed with 40.0% diisopropanolamine; Adding weight percentage is 0.2% corrosion inhibitor, adopting imidazoline-...

Embodiment 2

[0082] Under the premise of a certain content of MDEA and activator, the absorption performance of the decarburization solution with PZ as activator and the decarburization solution with TETA+DIPA as activator and corrosion inhibitor, stabilizer and defoamer were respectively tested For evaluation, in this example, the weight percentage of MDEA is 40%, and the weight percentage of activator is 4.0%. Experimental conditions: Absorption pressure: normal pressure (which can better reflect the difference in absorption effect), carbon dioxide content: 20% (mol), absorption temperature: 40°C and 60°C.

[0083] Table 1 Evaluation of absorption performance of two decarburization solutions at 40℃

[0084]

[0085] Table 2 Absorption performance evaluation of two decarburization solutions at 60℃

[0086]

[0087] From the data in Table 1 and Table 2, it can be seen that the carbon dioxide absorption capacity of the decarburization solution is significantly improved, and the maximum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com