Degradable absorptive poly lactic-co-glycolic acid (PLGA)-Mg series composite medical implant and preparation method thereof

A composite material, PLGA technology, applied in the field of biodegradable absorbable PLGA-Mg composite medical implants and its preparation, to achieve the effects of reducing corrosion rate, promoting adhesion and growth, and delaying degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The steps of the preparation method of the medical degradable and absorbable PLGA-Mg composite material implant of the present invention are as follows:

[0030] Step 1: Dissolve the polymer PLGA in dichloromethane at a mass volume ratio of 1:10. After the polymer PLGA is completely dissolved, add 0.5 to 4% magnesium wire according to the weight percentage of the polymer PLGA, and mechanically Stir well;

[0031] Step 2: At room temperature, after 2 / 3 of the dichloromethane volatilizes, pour the polymer PLGA solution on a polytetrafluoroethylene sheet, let the dichloromethane completely volatilize, and obtain PLGA-Mg on the polytetrafluoroethylene sheet Composite material sheet, remove the PLGA-Mg composite material sheet;

[0032] Step 3: Machining to make a dense structure PLGA-Mg system composite degradable material implant;

[0033] The mechanical processing method is hot pressing, and the hot pressing is to keep the PLGA-Mg composite material sheet obtained in st...

Embodiment 1

[0036] Dissolve PLGA in dichloromethane at a mass volume ratio of 1:10, and then divide it into two parts, and then add 2% and 4% magnesium with a length of 3mm to the two parts of the solution according to the weight percentage of the polymer PLGA. After the dichloromethane volatilizes 2 / 3, then pour the two mixed solutions with a certain viscosity on the polytetrafluoroethylene board, and after the mixed solvent is completely volatilized, remove the two parts from the polytetrafluoroethylene board. Composite material film, then preheat the two composite material films obtained above at 140°C for 15 minutes, after preheating, press at 20MPa and 120°C for 10 minutes to form two blanks, and wait for the blanks to be heated at room temperature PLGA-Mg composites were obtained after natural cooling

Embodiment 2

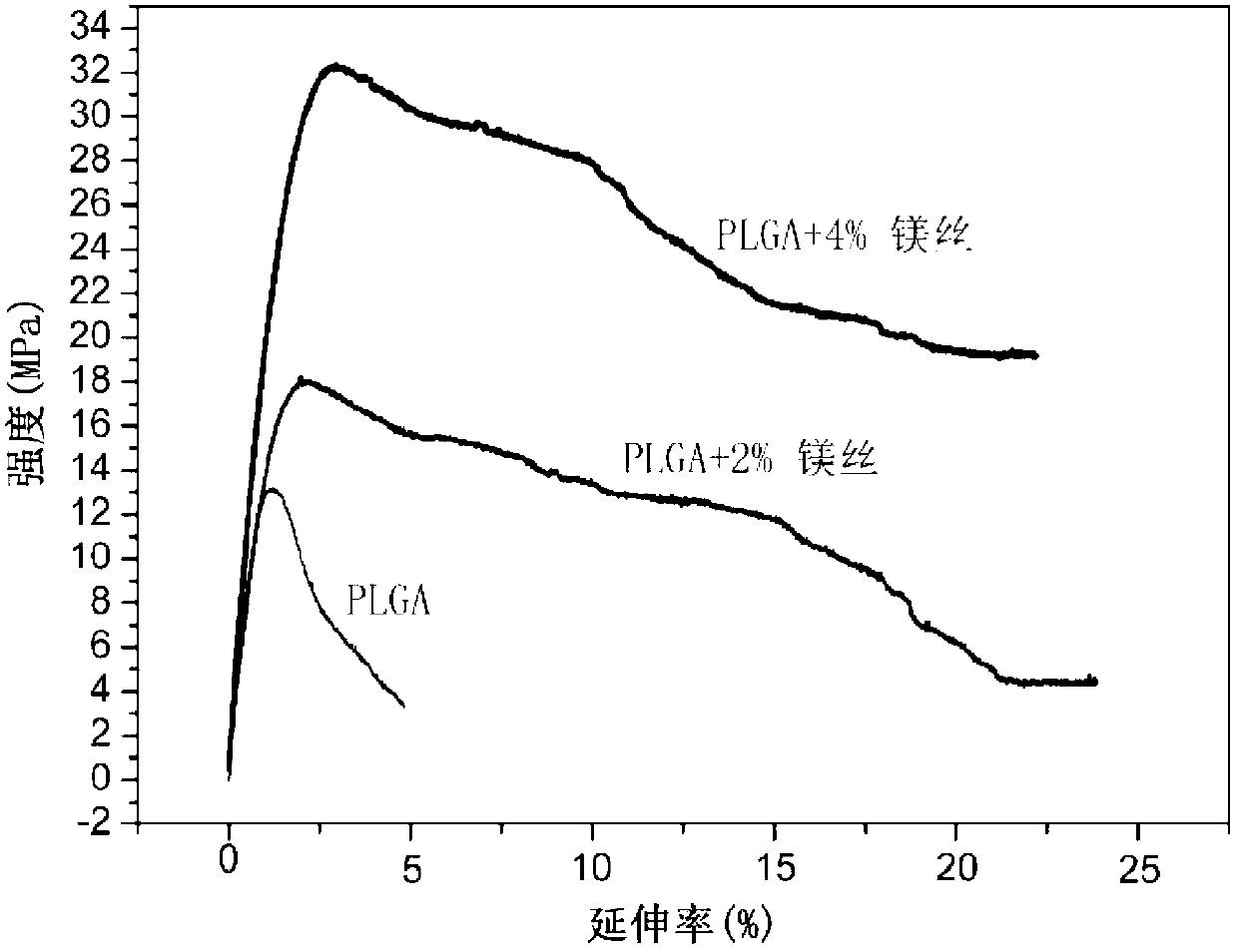

[0038] Two pieces of composite materials obtained in Example 1 are cut into width 2mm, length 40mm, thin sheet of thickness 1mm, carry out tensile test under room temperature condition, adopt 0.5mm / min tensile rate to stretch, obtain such as figure 1 The tensile property curve of the PLGA-Mg composite material at room temperature is shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com