Method for preparing lead tungstate nano-powder

A nano-powder, lead tungstate technology, applied in nanotechnology, chemical instruments and methods, tungsten compounds, etc., can solve the problems of large particle size, low specific surface area, waste of raw materials, etc., and achieve simple preparation method and post-processing Simple, Controllable Prepared Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Under room temperature conditions, prepare respectively 0.02mol / L sodium stearate aqueous solution A and 0.1mol / L lead nitrate aqueous solution B (zirconium nitrate containing 1000ppm); 100mlA and 10mlB are mixed (the ratio of the amount of substance is Fatty acid sodium salt: soluble lead salt = 2: 1); after standing, filter and wash to obtain a precipitate of 0.001molC;

[0034] (2) Dissolve 0.001mol C in 100ml xylene to form a transparent emulsion D at a temperature of 90°C and a stirring speed of 5000r / min;

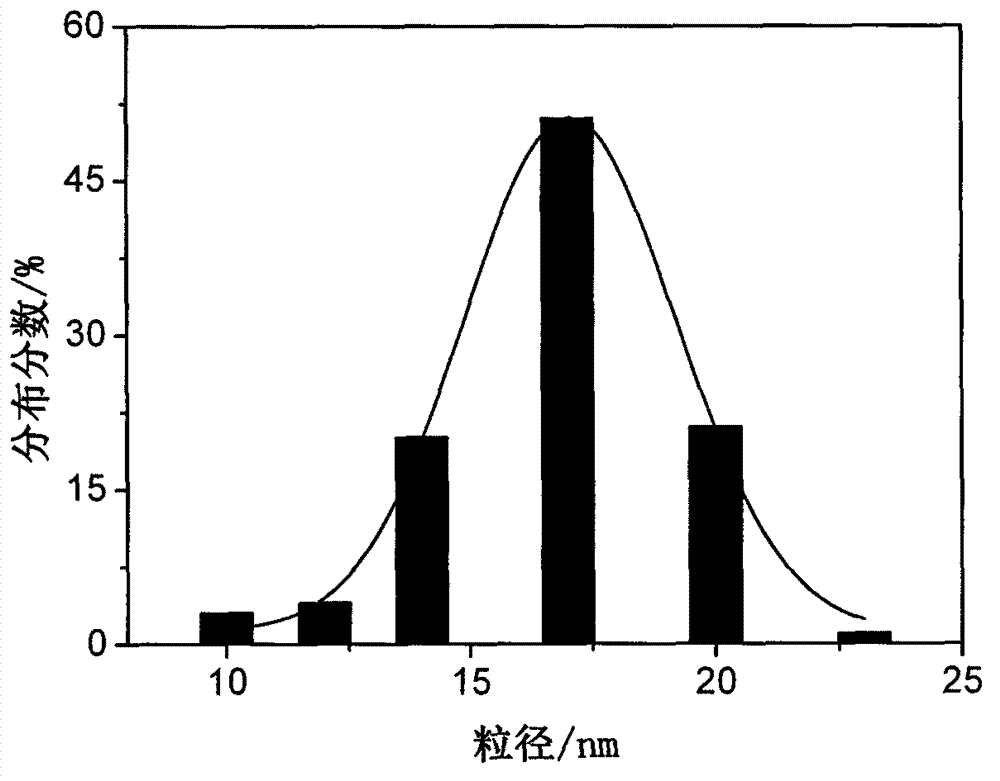

[0035] (3) Prepare 0.1mol / L tungstate aqueous solution; under the conditions of temperature 70°C and 5000r / min stirring speed, add 10ml of tungstate aqueous solution to D to form transparent / translucent emulsion E; The size adopts nanometer particle size analyzer (U.S., Malvern), and the size of nanoparticle is 14nm~20nm ( figure 1 );

[0036] (4) Cool to room temperature after the reaction, let it stand, wash the precipitate with ethanol and deionized wa...

Embodiment 2

[0038] (1) Under room temperature conditions, prepare 0.5mol / L sodium octanoate aqueous solution A and 1mol / L lead nitrate aqueous solution B respectively; 100mlA and 25mlB are mixed; After standing, filter and wash to obtain precipitate 0.025molC;

[0039] (2) Dissolve 0.025mol C in 100ml n-octane under the conditions of temperature 70°C and stirring speed 1000r / min to form transparent emulsion D;

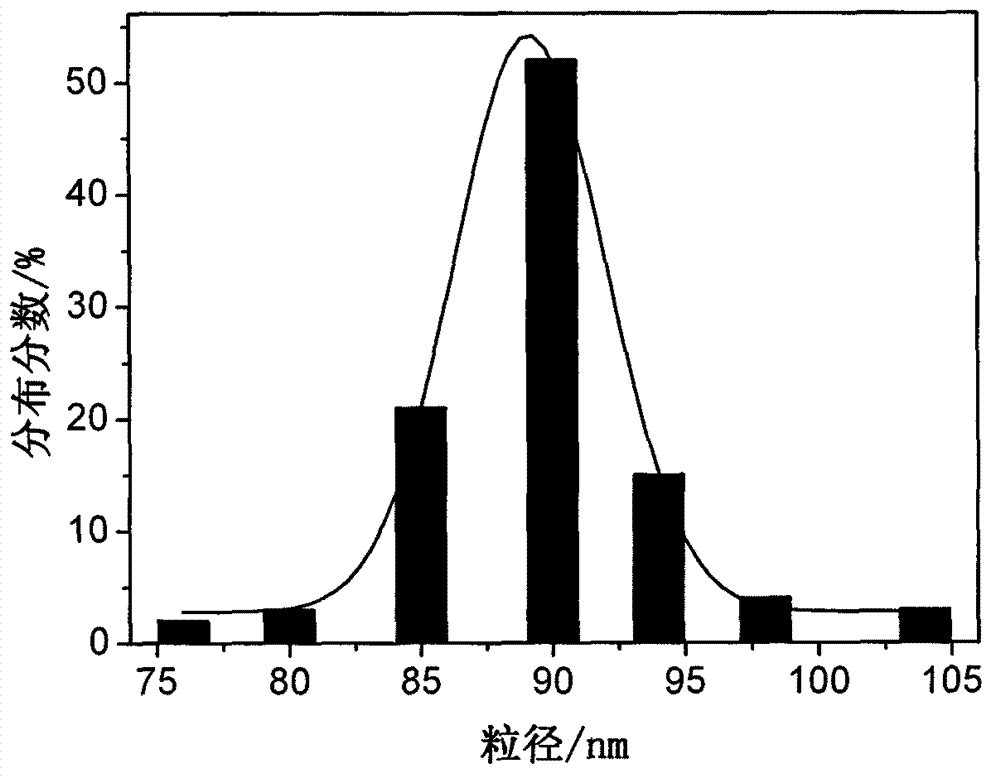

[0040] (3) Prepare 0.125mol / L sodium tungstate aqueous solution; under the conditions of temperature 70°C and 1000r / min stirring speed, add 80ml of tungstate aqueous solution to D to form transparent / translucent emulsion E; latex particles The size adopts nanometer particle size analyzer (U.S., Malvern), and the size of nanoparticle is 85~95nm ( figure 2 );

[0041] (4) Cool to room temperature after the reaction, let it stand, wash the precipitate with ethanol and deionized water in turn, then dry at 100°C, and finally calcinate at 700°C in a muffle furnace for 4 hours to obtai...

Embodiment 3

[0043] (1) At room temperature, prepare 0.1mol / L sodium dodecylsulfonate aqueous solution A and 0.1mol / L lead nitrate aqueous solution B (containing 10ppm yttrium nitrate) respectively; mix 100mlA and 50mlB; filter after standing , washing to obtain a precipitate of 0.01molC;

[0044](2) Dissolve 0.01mol C in 100ml kerosene at a temperature of 60°C and a stirring speed of 3000r / min to form a transparent emulsion D;

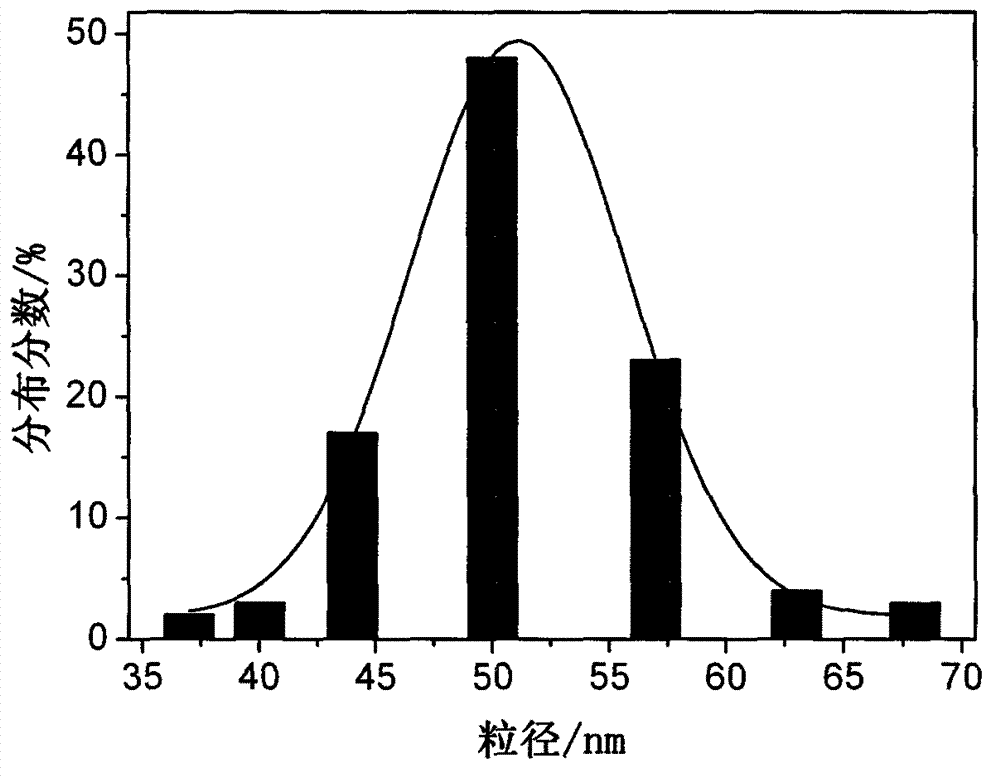

[0045] (3) Prepare 0.25mol / L tungstate aqueous solution; under the conditions of temperature 70°C and 5000r / min stirring speed, add 40ml of tungstate aqueous solution dropwise to D to form translucent emulsion E; the size of latex particles adopts Nanoparticle size analyzer (USA, Malvern), the size of nanoparticles is 44 ~ 57nm ( image 3 );

[0046] (4) After the reaction is finished, cool to room temperature, let it stand, and wash the precipitate with ethanol and deionized water in turn, then dry it at 100°C, and finally calcinate it in a muffle furnace at 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com