Aluminum nitride solid-state laser and preparation method thereof

A solid-state laser, aluminum nitride technology, applied in the direction of the structure/shape of the active medium, active medium materials, etc., can solve the problems of high cost and complex structure, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

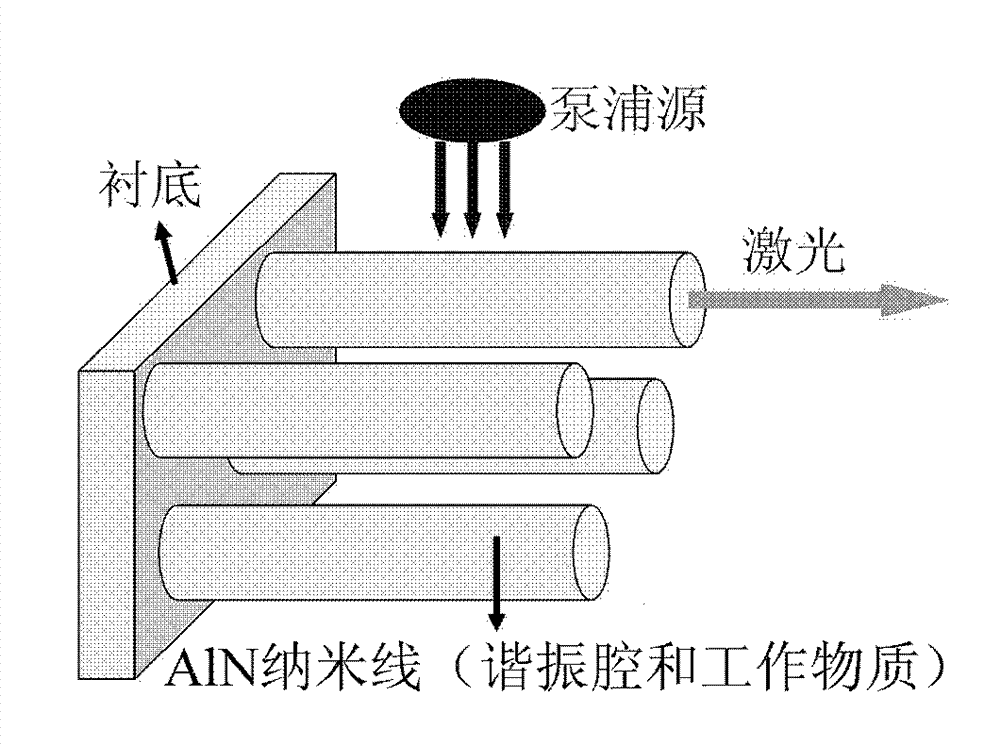

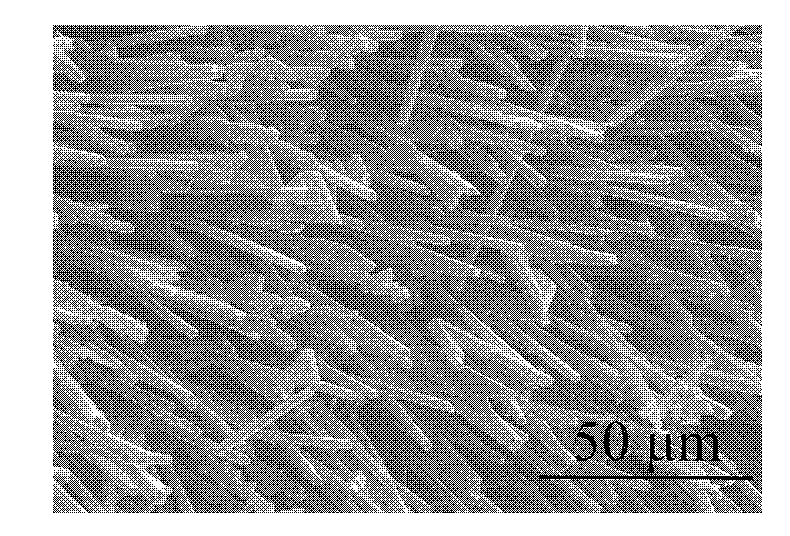

[0034] According to an embodiment of the present invention, a Fe-based 3+ : Aluminum Nitride Solid State Lasers with AlN Nanowire Arrays. Such as figure 2 shown, including the pump source, Fe 3+ :AlN nanowire array and supporting Fe 3+ : The substrate of AlN nanowire array, in which the pump source adopts the laser with the wavelength of 532nm along the Fe 3+ : Pumping from the side of the AlN nanowire array. The working principle of the laser is: when the incident Fe 3+ : When the laser energy on the AlN nanowire exceeds the threshold, AlN produces stimulated radiation, but because AlN has a large refractive index, the light propagates in the nanowire and is reflected and amplified back and forth on the two ends of the nanowire, and finally from the end part of the output laser, so the Fe 3+ : AlN nanowire itself can also be used as an optical resonant cavity. It can be seen that in this laser, Fe 3+ : AlN nanowires can have the functions of a resonant cavity and a w...

Embodiment 2

[0040] Embodiment 2 provides another Fe-based 3+ : the aluminum nitride laser of AlN nanowire array, its difference with embodiment 1 is that Fe 3+ : Fe in AlN nanowire array 3+ The doping concentration, the method comprises the following steps:

[0041] According to the stoichiometric ratio, 4.2g of AlN powder with a purity of 99.99% and 0.4g of Fe powder with a purity of 99.99% were mixed, ground evenly, put into a tantalum carbide crucible, covered with a tantalum carbide cover, and then Put the tantalum crucible into the graphite crucible, screw on the lid of the graphite crucible, put the graphite crucible into an appropriate position in the medium frequency induction heating furnace, and evacuate the system until the vacuum degree is less than 2.0×10 -5 After Torr, fill the cavity with 0.6atm high-purity N 2 Gas (99.999%). Then the system was heated up to 1300°C at a rate of 4°C per minute, and after being kept at 1300°C for 2 hours, it was cooled to room temperature...

Embodiment 3

[0046] Embodiment 3 is a kind of based on Mn 3+ : the aluminum nitride laser of the AlN nanowire array, the principle and structure of the laser are basically the same as in Embodiment 1, and the difference is only in the difference of the doping element and its concentration, that is, the Mn 3+ : AlN nanowire array as Mn 3+ The doping concentration is an AlN nanowire array of 0.05 at.%, so its preparation method includes the following steps:

[0047] According to the stoichiometric ratio, 4.2g of AlN powder with a purity of 99.99% and 0.2g of Mn powder with a purity of 99.99% were mixed, ground evenly, put into a tantalum carbide crucible, covered with a tantalum carbide cover, and then Put the tantalum crucible into the graphite crucible, screw on the lid of the graphite crucible, put the graphite crucible into an appropriate position in the medium frequency induction heating furnace, and evacuate the system until the vacuum degree is less than 2.0×10 -5 After Torr, fill t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com