Bactericide used for reverse osmosis membrane and preparation method thereof

A technology of reverse osmosis membrane and bactericide, which is applied in the field of high-efficiency bactericide and its preparation, can solve the problems of inconvenient operation, affecting the normal operation of production, and no bactericide, etc., to achieve enhanced bactericidal performance and stability, good synergistic effect, The effect of enhancing the bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] It is composed of deionized water, solvent, bromocyanopropionamide, bronopol and additives. Its weight percent composition is that bromocyanopropionamide is 2,2-dibromo-2-cyanoacetamide, accounting for 20%, bronopol is 2-bromo-2-nitro-1,3-propanediol, accounting for 5%, the solvent is polyethylene glycol PEG200, accounting for 40%, the auxiliary agent is citric acid, accounting for 10%, and the balance of deionized water.

[0020] Add polyethylene glycol PEG200 into the reaction kettle at room temperature, add 2,2-dibromo-2-cyanoacetamide and 2-bromo-2-nitro-1,3-propanediol and stir to dissolve for 50~60 minutes, then Add citric acid and deionized water, stir for 20-30 minutes, and stand still for 10 minutes to obtain this product.

Embodiment 2

[0022] It is composed of deionized water, solvent, bromocyanopropionamide, bronopol and additives. Its weight percent composition is that bromocyanopropionamide is 2,2-dibromo-2-cyanoacetamide, accounting for 25%, and bronopol is 2-bromo-2-nitro-1,3-propanediol, accounting for 10%, the solvent is ethylene glycol, accounting for 50%, the auxiliary agent is lactic acid, accounting for 5%, and the balance is deionized water.

[0023] Add ethylene glycol into the reaction kettle at room temperature, add 2,2-dibromo-2-cyanoacetamide and 2-bromo-2-nitro-1,3-propanediol and stir to dissolve for 50~60 minutes, then add lactic acid Stir with deionized water for 20-30 minutes, and stand still for 10 minutes to obtain this product.

Embodiment 3

[0025] It is composed of deionized water, solvent, bromocyanopropionamide, bronopol and additives. Its weight percent composition is that bromocyanopropionamide is 2,2-dibromo-2-cyanoacetamide, accounting for 30%, and bronopol is 2-bromo-2-nitro-1,3-propanediol, accounting for 7%, the solvent is ethanol accounting for 30%, diethylene glycol accounting for 30%, the auxiliary agent is urea accounting for 1%, and the balance of deionized water.

[0026] Add ethanol and diethylene glycol into the reaction kettle at room temperature, add 2,2-dibromo-2-cyanoacetamide and 2-bromo-2-nitro-1,3-propanediol and stir to dissolve for 50-60 minutes, then Add urea and deionized water, stir for 20-30 minutes, and let stand for 10 minutes to obtain this product.

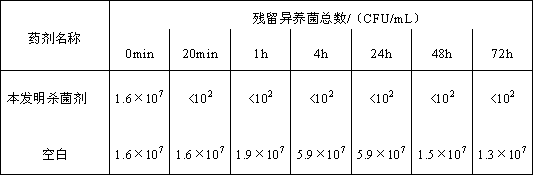

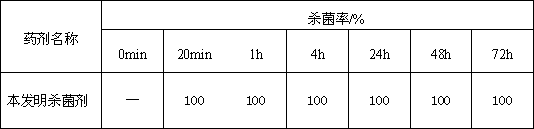

[0027] The reverse osmosis membrane bactericide of the present invention can quickly penetrate the cell membrane of microorganisms and act on certain protein groups to stop the normal oxidation and reduction of cells, thereby causin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com