Optimum method for co-producing melamine and urea

A technology of melamine and urea, applied in chemical instruments and methods, preparation of organic compounds, chemical industry, etc., can solve problems such as unfavorable long-distance transportation, easy bonding, small volume flow, etc., and achieve the effect of ensuring long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: a kind of method of co-production of melamine and urea optimized, described melamine production process refers to the gas phase quenching low-pressure circulation method technology that takes urea as raw material, and described urea plant refers to CO 2 Gas stripping urea plant.

[0018] CO of the present invention 2 Gas stripping urea plant and conventional CO 2 Compared with the stripping urea plant: a. Increase the medium-pressure flash heating and decomposition operation unit, and the pressure is preferably 1.8~2.2 MPa (A).

[0019] b. Add a urine pre-concentrator to recycle the condensation heat of the medium-pressure decomposition gas.

[0020] c. Increase the operation unit of the excess ammonia separation and rectification tower, which is used to separate the excess ammonia in the low-pressure decomposition gas to control the pressure of the urea low-pressure decomposition system. Ammonium solution is low-pressure methylamine solution I.

[002...

Embodiment 2

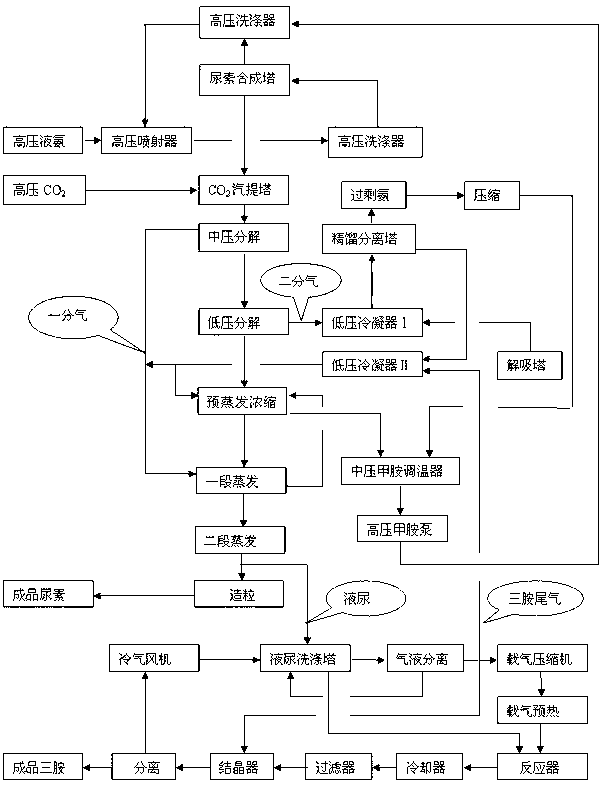

[0023] Embodiment 2: as figure 1 As shown, an optimized method for the co-production of melamine and urea, the melamine production process adopts low-pressure gas phase or solid phase quenching melamine tail gas with a pressure above 0.4MPa, which is discharged from the front branch of the carrier gas circulation compressor and directly sent to the urea plant. Cogeneration method of low pressure condensation absorption section.

[0024] CO 2 In the gas stripping urea plant, a medium-pressure flash heating decomposition section with a pressure of 1.8-2.2 MPa (A) is added between the high-pressure section and the low-pressure section. A gas-phase or solid-phase quenching melamine tail gas condensation absorption operation unit is added. The low-pressure decomposition gas is mixed with the outlet gas of the desorption tower of the urea plant and condensed into a low-pressure methylamine liquid Ⅰ, and the melamine tail gas is mixed with the low-pressure methylamine liquid Ⅰ to en...

Embodiment 3

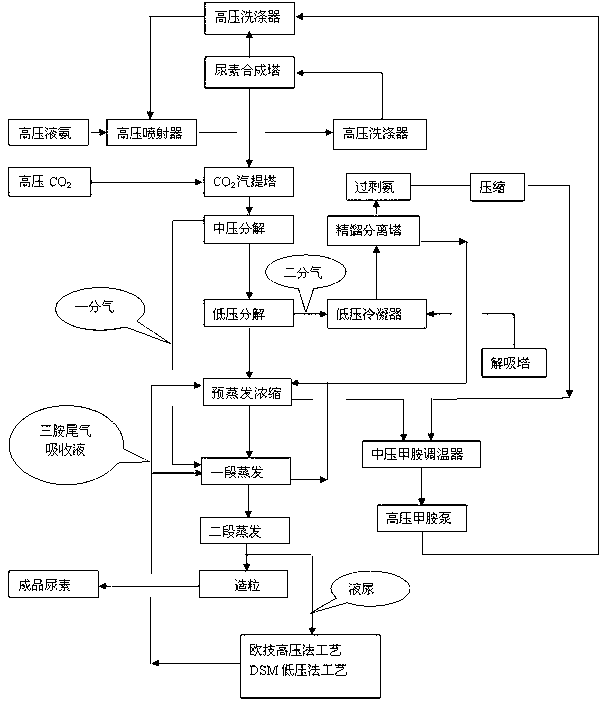

[0026] Embodiment 3: as figure 2 As shown, an optimized method for the co-production of melamine and urea, the melamine production process adopts the Ouzhi high-pressure method or the DSM low-pressure method, and the melamine tail gas absorption liquid is directly sent to the urine pre-concentrator and the first-stage evaporator of the urea plant. . The absorption liquid is methyl ammonium liquid.

[0027] CO 2 In the gas stripping urea plant, a urine pre-concentrator is added after the low-pressure decomposition section to recover and utilize the condensation heat of the medium-pressure decomposition gas. The methylamine liquid in the tail gas of the melamine production process is directly mixed with the medium-pressure decomposition gas of the urea plant through a part of the medium-pressure methylamine pump and sent to the shell side of the first-stage evaporator. Ammonium methyl solution and uncondensed NH 3 , CO 2 And water vapor mixed with the remaining triamine ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com