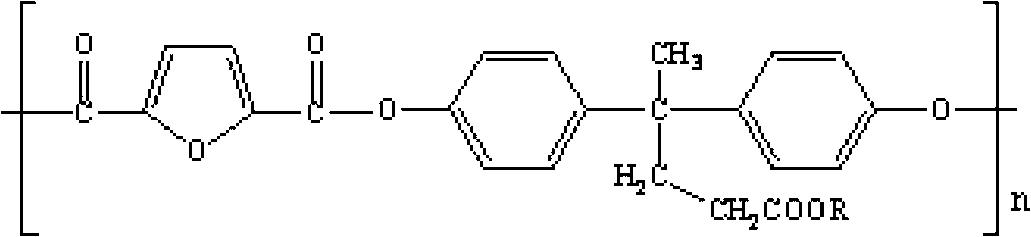

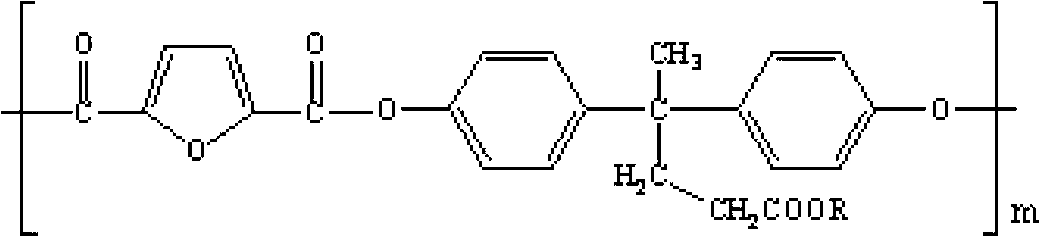

Biobased polyarylester and preparation method thereof

A polyarylate, bio-based technology, applied in the field of bio-based polyarylate and its preparation, can solve the problems of high price, limited production of terephthalic acid, and industrialized production has not been realized, and achieves the effect of excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

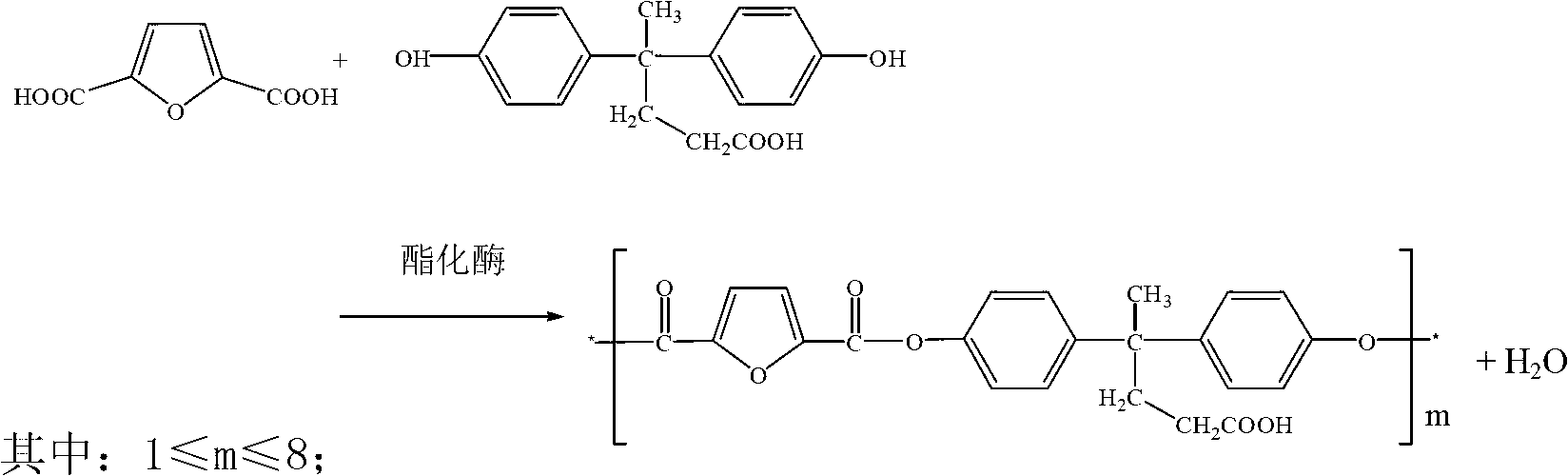

[0038] 1. Esterification reaction

[0039] Add 2,5-furandicarboxylic acid and bisphenolic acid into 1,4-dioxane solvent, stir to dissolve, and preheat to 45°C to prepare a mixed solution, in which 2,5-furandicarboxylic acid , The weight ratio between bisphenolic acid and 1,4-dioxane is 10:30:60, and the molar ratio of 2,5-furandicarboxylic acid to bisphenolic acid is 1:1.56;

[0040] Send the above mixed solution into the tank-type bioreactor, then add the above-mentioned immobilized esterification enzyme, and carry out the esterification reaction under steam heating and pulse agitation, and pulse agitation for 3-5 minutes every 4-6 hours during the reaction process. And detect the acidity, stop the reaction when the acidity no longer decreases, recover the immobilized esterification enzyme, remove the solvent and water by distillation under reduced pressure, and obtain the esterification product; wherein the weight ratio of the esterification enzyme to the mixed solution is 0...

Embodiment 2

[0050] 1. Esterification reaction

[0051] Add 2,5-furandicarboxylic acid and bisphenolic acid into tetrahydrofuran solvent, stir to dissolve, and preheat to 40°C to obtain a mixed solution, in which the mixture of 2,5-furandicarboxylic acid, bisphenolic acid and tetrahydrofuran The weight ratio between them is 12:23:65, and the molar ratio of 2,5-furandicarboxylic acid to bisphenolic acid is 1:1;

[0052] Send the above mixed solution into the tank-type bioreactor, then add the above-mentioned immobilized esterification enzyme, and carry out the esterification reaction under steam heating and pulse agitation, and pulse agitation for 3-5 minutes every 4-6 hours during the reaction process. And detect the acidity, stop the reaction when the acidity no longer decreases, recover the immobilized esterase, remove the solvent and water by distillation under reduced pressure, and obtain the esterification product, wherein the weight ratio of the esterase to the mixed solution is 0.1:...

Embodiment 3

[0056] 1. Esterification reaction

[0057] Add 2,5-furandicarboxylic acid and bisphenolic acid methyl ester into acetone solvent, stir to dissolve, then preheat to 50°C to obtain a mixed solution, in which 2,5-furandicarboxylic acid, bisphenolic acid methyl The weight ratio between ester and acetone is 2:38:60, and the molar ratio of 2,5-furandicarboxylic acid to bisphenolic acid methyl ester is 1:10;

[0058] Send the above mixed solution into the tank-type bioreactor, then add lipase LS-20 for esterification, mix well and then carry out the esterification reaction under steam heating and pulse agitation, and pulse agitation every 4-6 hours during the reaction process 3-5 minutes, and check the acidity. When the acidity no longer decreases, the reaction is terminated. After the solvent and water are removed by distillation under reduced pressure, the esterification product is obtained. The weight ratio of the enzyme to the mixed solution is 2:100, and the esterification is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com