Method for preparing melamine-formaldehyde resin fluorescent microspheres

A technology of melamine and fluorescent microspheres, which is applied in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of uniformity reduction of microspheres, limitation of dye types, restrictions, etc., and achieve good monodispersity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

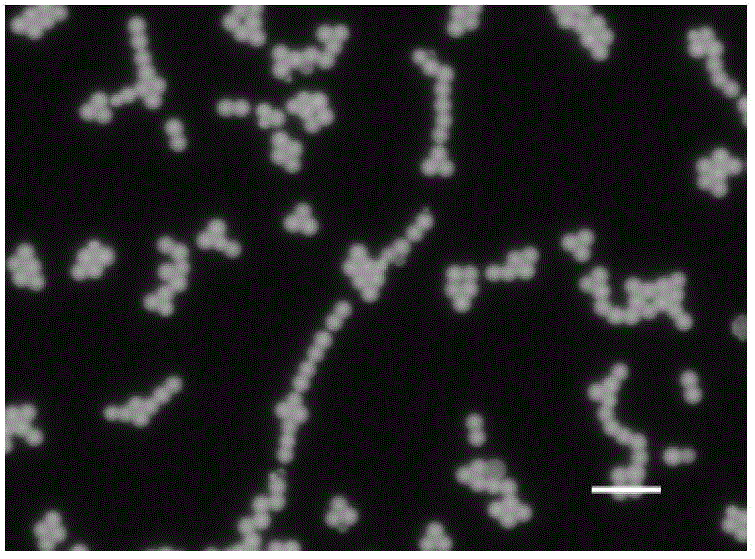

[0021] Prepare fluorescein-melamine-formaldehyde resin fluorescent microspheres, comprising the following steps:

[0022] Step 1. Mix 2.6 g of melamine and 11 g of formaldehyde solution with a mass percent concentration of 40%, add 0.1 mol / L nitric acid solution, adjust the pH to 4, and stir and react at 80°C to prepare a soluble prepolymer of melamine-formaldehyde solution;

[0023] Step 2, adding fluorescent dye fluorescein to the prepolymer solution obtained in step 1, the mass ratio of the added fluorescent dye to melamine is 1.5:100, the dye molecules are adsorbed and wrapped inside the branched prepolymer molecules, Obtain the prepolymer solution that encapsulates the dye;

[0024] Step 3, mixing the dyed prepolymer solution obtained in step 2 with deionized water, the ratio of deionized water to melamine is 10:0.3 by mass ratio, adding 0.1mol / L sodium hydroxide solution to adjust the pH of the system to be 6 , and reacted at 80°C for 40 minutes. During this process, i...

Embodiment 2

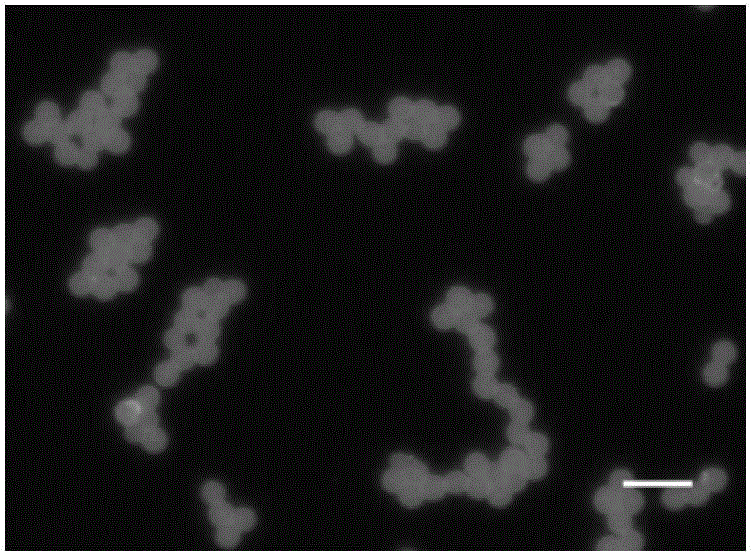

[0028] Prepare coumarin 30-melamine-formaldehyde resin fluorescent microspheres, comprising the following steps:

[0029] Step 1. Mix 2.6 g of melamine and 5.2 g of formaldehyde solution with a mass percent concentration of 40%, add 0.1 mol / L nitric acid solution, adjust the pH to 6, and stir and react at 20°C to prepare a soluble prepolymer of melamine-formaldehyde substance solution;

[0030] Step 2. Add fluorescent dye coumarin 30 dye powder to the prepolymer solution obtained in step 1. The mass ratio of the added fluorescent dye to melamine is 1:100. The dye molecules are adsorbed and wrapped in the branched prepolymer solution. Inside the molecule, the prepolymer solution wrapped with the dye is obtained;

[0031] Step 3, mixing the dyed prepolymer solution obtained in step 2 with deionized water, the ratio of deionized water to melamine is 10:0.4 by mass ratio, adding 0.1mol / L nitric acid solution to adjust the pH of the system to be 2, and then React at 90°C for 40 m...

Embodiment 3

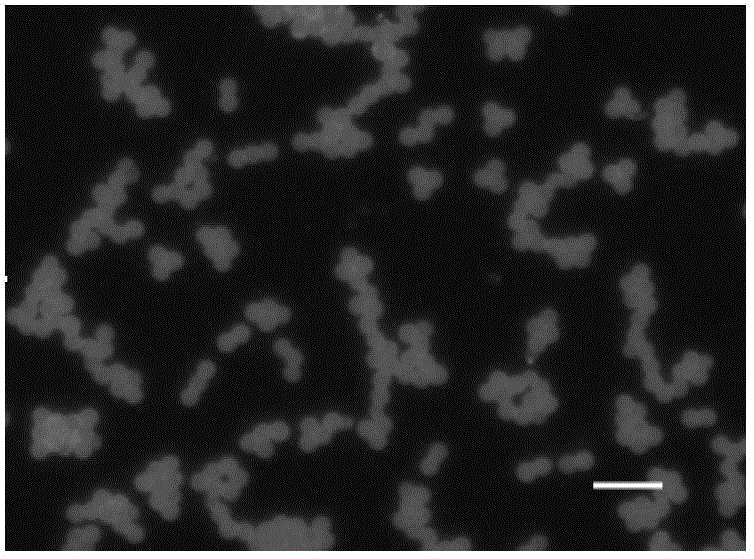

[0034] The preparation of acridine orange-melamine-formaldehyde resin fluorescent microspheres includes the following steps:

[0035] Step 1. Mix 2.6 g of melamine and 11 g of formaldehyde solution with a mass percentage concentration of 40%, add 0.1 mol / L sodium hydroxide solution, adjust the pH to 9, and stir the reaction at 50 ° C to prepare the soluble pre-melamine-formaldehyde solution. polymer solution;

[0036] Step 2: Add the fluorescent dye acridine orange dye powder into the prepolymer solution obtained in step 1, and the mass ratio of the added fluorescent dye to the mass of melamine is 0.5:100, and the dye molecules are adsorbed and wrapped in the branched prepolymer. Inside the molecule, the prepolymer solution encapsulated with the dye is obtained;

[0037] Step 3: Mix the dyed prepolymer solution obtained in step 2 with deionized water, the ratio of deionized water to melamine is 10:0.3 by mass ratio, add 0.1mol / L nitric acid solution to adjust the pH of the sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com