Epoxy resin-POSS hybrid resin and preparation method of its composite material

An epoxy resin and hybrid resin technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of high cross-linking degree of cured products and incomplete reaction of active groups, and achieve Good overall performance, avoid incomplete reaction, improve the effect of glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

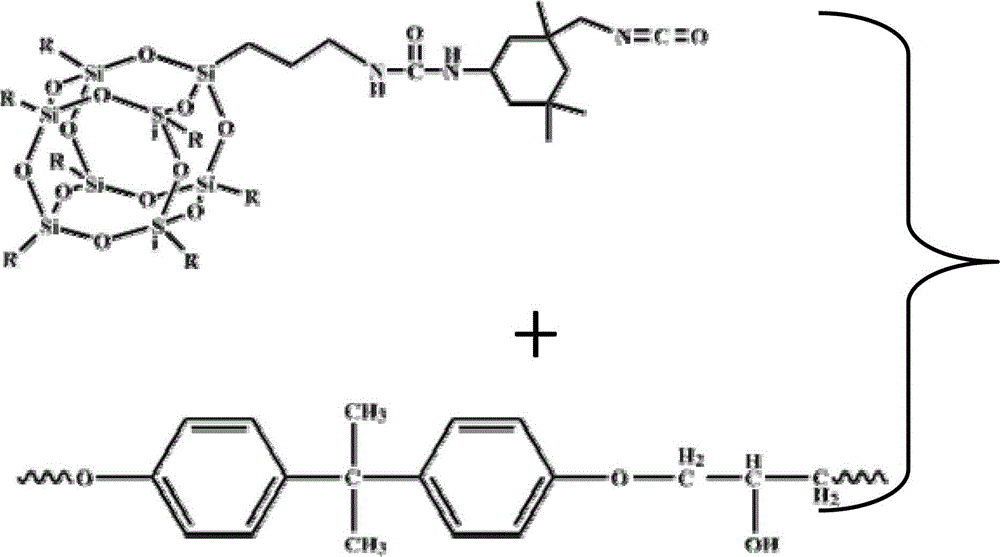

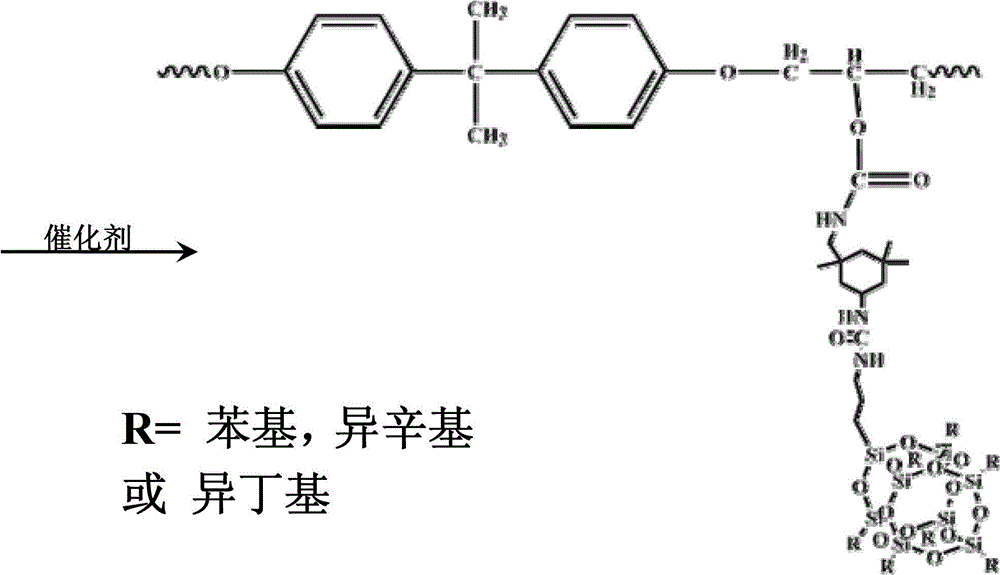

Method used

Image

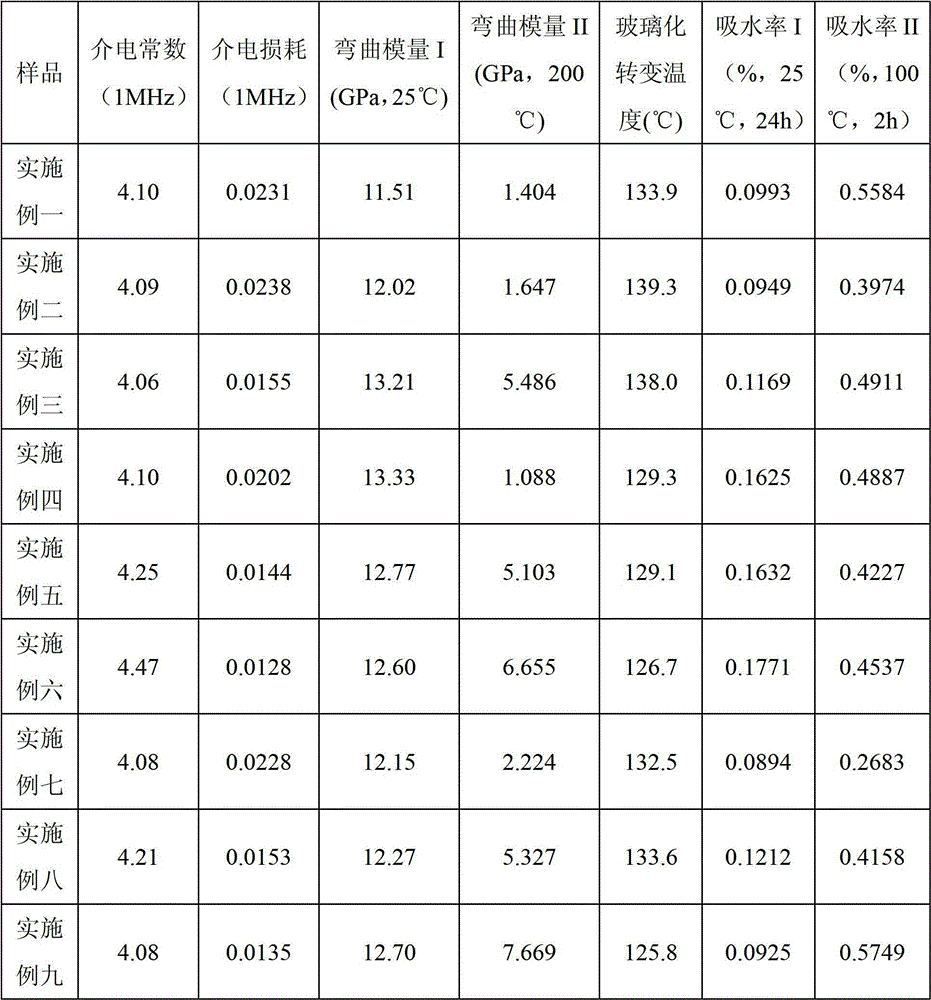

Examples

Embodiment 1

[0014] Embodiment one: 50g brominated bisphenol A type epoxy resin is dissolved in 12.5g acetone, is made into the resin glue solution of 80wt%, gets 0.5g heptaphenyl monoisocyanate group cage type silsesquioxane and is dissolved in 5g After fully dissolving in chloroform, mix it into the resin glue solution, add 0.1 g of dibutyltin dilaurate solution of 20 wt% catalyst, stir evenly, and react at 60°C for 5 hours to obtain a hybrid resin. Add 12.5g of 10% mass fraction of dicyandiamide in N,N-dimethylformamide solution, add 7.5g of 1% mass fraction of 2-methylimidazole in acetone solution, and stir for 12 hours. Take six pieces of glass fiber cloth and dip them into the resin one by one, soak them fully, and cure the glued glass fiber cloth in an oven at 170°C for 6 minutes to obtain a prepreg. Put it into a hot press without slipping each layer, pressurize to 3.5Mpa, keep the pressure stable until the board is taken out, keep it at 140°C for 1 hour, raise the temperature to 2...

Embodiment 2

[0015] Embodiment two: 50g brominated bisphenol A type epoxy resin is dissolved in 12.5g acetone, is made into the resin glue solution of 80wt%, gets 1.5g heptaphenyl monoisocyanate group cage type silsesquioxane and dissolves in 15g After fully dissolving in chloroform, mix it into the resin glue solution, add 0.3 g of dibutyltin dilaurate solution with 20 wt% catalyst, stir evenly, and react at 60°C for 5 hours to obtain a hybrid resin. Add 12.5g of 10% mass fraction of dicyandiamide in N,N-dimethylformamide solution, add 7.5g of 1% mass fraction of 2-methylimidazole in acetone solution, and stir for 12 hours. Take six pieces of glass fiber cloth and dip them into the resin one by one, soak them fully, and cure the glued glass fiber cloth in an oven at 170°C for 6 minutes to obtain a prepreg. Put it into a hot press without slipping each layer, pressurize to 3.5Mpa, keep the pressure stable until the board is taken out, keep it at 140°C for 1 hour, raise the temperature to 2...

Embodiment 3

[0016] Embodiment three: 50g brominated bisphenol A type epoxy resin is dissolved in 12.5g acetone, is made into the resin glue solution of 80wt%, gets 2.5g heptaphenyl monoisocyanate group cage type silsesquioxane and is dissolved in 25g After fully dissolving in chloroform, mix it into the resin glue solution, add 0.5 g of a 20 wt % dibutyltin dilaurate solution as a catalyst, stir evenly, and react at 60° C. for 5 hours to obtain a hybrid resin. Add 12.5g of 10% mass fraction of dicyandiamide in N,N-dimethylformamide solution, add 7.5g of 1% mass fraction of 2-methylimidazole in acetone solution, and stir for 12 hours. Take six pieces of glass fiber cloth and dip them into the resin one by one, soak them fully, and cure the glued glass fiber cloth in an oven at 170°C for 6 minutes to obtain a prepreg. Put it into a hot press without slipping each layer, pressurize to 3.5Mpa, keep the pressure stable until the board is taken out, keep it at 140°C for 1 hour, raise the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com