Lithium ion secondary battery negative electrode slurry composition, a lithium ion secondary battery negative electrode, and lithium ion secondary battery

A secondary battery and lithium ion technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of increasing plate density, deteriorating input and output characteristics, and low crystallinity, so as to improve the bonding strength and life span Characteristics, absorption-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0165] (Manufacture of Adhesives)

[0166] Add 46 parts of styrene, 49 parts of 1,3-butadiene, 5 parts of methacrylic acid, 5 parts of sodium dodecylbenzenesulfonate, 150 parts of ion-exchanged water, 1 part of potassium persulfate as a polymerization initiator was stirred sufficiently, and then heated to 50° C. to initiate polymerization. Cool when the monomer consumption reaches 95.0%, terminate the reaction, and obtain a diene-based polymer particle dispersion (the number-average particle diameter of the polymer particles: 100 nm, polymerized The glass transition temperature of the material particle: -15°C). It should be noted that, in the monomer composition used to obtain diene polymer particles, 5% by mass of monocarboxylic acid monomer (methacrylic acid) was included, and the amount of surface acid groups per 1 g of polymer particles was 0.30 mmol.

[0167] (Manufacture of slurry composition for negative electrode of lithium ion secondary battery)

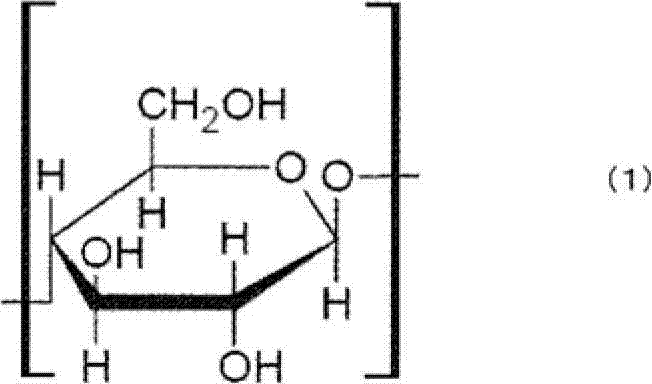

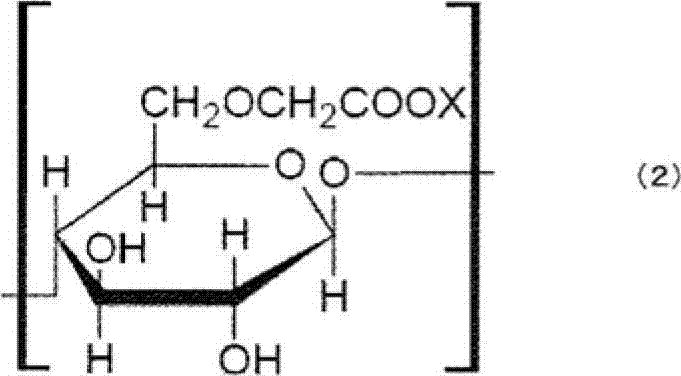

[0168] Carboxyme...

Embodiment 2

[0176] The thickener was replaced by carboxymethyl cellulose with a degree of polymerization of 1420 and a degree of etherification of 0.7, except that the same operation as in Example 1 was carried out to make a slurry composition, negative electrode and half-cell, and to It evaluates. The results are shown in Table 1.

Embodiment 3

[0178] (Manufacture of Adhesives)

[0179] Add 50 parts of styrene, 48.5 parts of 1,3-butadiene, 1.5 parts of methacrylic acid, 5 parts of sodium dodecylbenzenesulfonate, 150 parts of ion-exchanged water, 1 part of potassium persulfate as a polymerization initiator was stirred sufficiently, and then heated to 50° C. to initiate polymerization. Cool when the monomer consumption reaches 95.0%, terminate the reaction, and obtain a diene-based polymer particle dispersion (number-average particle diameter of the polymer particle: 105 nm, polymerized The glass transition temperature of the material particle: -18°C). It should be noted that, in the monomer composition used to obtain diene-based polymer particles, 1.5% by mass of monocarboxylic acid monomer (methacrylic acid) was included, and the amount of surface acid groups per 1 g of polymer particles was 0.11 mmol.

[0180] Except for using the above-mentioned binder, the same operation as in Example 1 was carried out to prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| face spacing | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com