Novel rubber tire isolation release agent and preparation method thereof

A rubber tire and release agent technology, applied in the field of rubber additives, to achieve the effects of easy use, mold surface protection and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

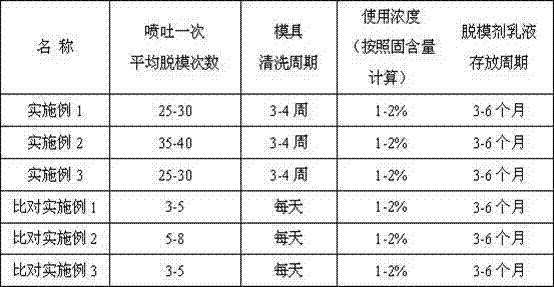

Examples

Embodiment 1

[0015] (1) Accurately measure 60ml of ethanol, 30ml of propylene glycol, 25ml of distilled water, weigh 4.0g of emulsifier OP-10, weigh 1.6g of sodium stearate, and 15ml of calcium chloride solution with a concentration of 1M. In a 250ml three-neck flask, stir to form a transparent solution. Make sodium carbonate into an aqueous solution with a concentration of 1M, accurately pipette 15.15ml of sodium carbonate solution, slowly add it dropwise into a three-necked flask, and stir while adding dropwise. -1h to obtain active nano-calcium carbonate dispersion emulsion. The average particle size of the nano-calcium carbonate determined by the light scattering method is 40-60nm, and the crystal form of the nano-calcium carbonate is cubic when observed by a transmission electron microscope.

[0016] (2) Weigh 40g of polyethylene glycol with an average molecular weight of 2000, 4.0g of emulsifier OP-10, 1.0g of emulsifier Textol 1310, measure 80ml of distilled water, add it into a 25...

Embodiment 2

[0020] (1) Accurately measure 70ml of absolute ethanol, 10ml of ethylene glycol, weigh 5 g of polyethylene glycol (average molecular weight 1000) aqueous solution with a concentration of 2% by mass, 1.5g of emulsifier AEO3, 4.0g of emulsifier Textol 1310, 7.5g oleic acid, 30ml calcium chloride solution with a concentration of 1M, add it into a 250ml three-neck flask with a stirring reflux device, and stir to form a transparent solution. Make sodium carbonate into an aqueous solution with a concentration of 1M, accurately pipette 30.5ml of sodium carbonate solution, slowly add it dropwise into a three-necked flask, and stir while adding dropwise. -3.0h to obtain active nano-calcium carbonate dispersion emulsion. The average particle size of the nano-calcium carbonate determined by the light scattering method is 40-60nm, and the crystal form of the nano-calcium carbonate is cubic when observed by a transmission electron microscope.

[0021] (2) Weigh 40g of silicone oil with an...

Embodiment 3

[0024] (1) Accurately measure 17ml of absolute ethanol, 10g of polyethylene glycol (average molecular weight 1000) aqueous solution with a concentration of 3% by mass, weigh 2.0g of emulsifier TW60, 0.5g of emulsifier TW80, weigh Take 6.25g of stearic acid and 52.63ml of calcium chloride solution with a concentration of 2.5M, add them into a 250ml three-necked flask with a stirring reflux device, and stir to form a transparent solution. Make sodium carbonate into an aqueous solution with a concentration of 2.5M, accurately pipette 50.5ml of sodium carbonate solution, slowly add it dropwise into a three-necked flask, and stir while adding dropwise. 0.5h to obtain active nano-calcium carbonate dispersion emulsion. The average particle size of the nano-calcium carbonate determined by the light scattering method is 40-60nm, and the crystal form of the nano-calcium carbonate is cubic when observed by a transmission electron microscope.

[0025] (2) Weigh 40 g of polyethylene wax w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com