Method for determining content of phosphor in ferrotungsten

A method of determination, technology of phosphorus content, applied in the direction of measuring device, preparation of test samples, material analysis through electromagnetic means, etc., can solve problems such as long time required, cumbersome procedures, interference, etc., and achieve simple preparation process and detection The effect of simple process and material cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

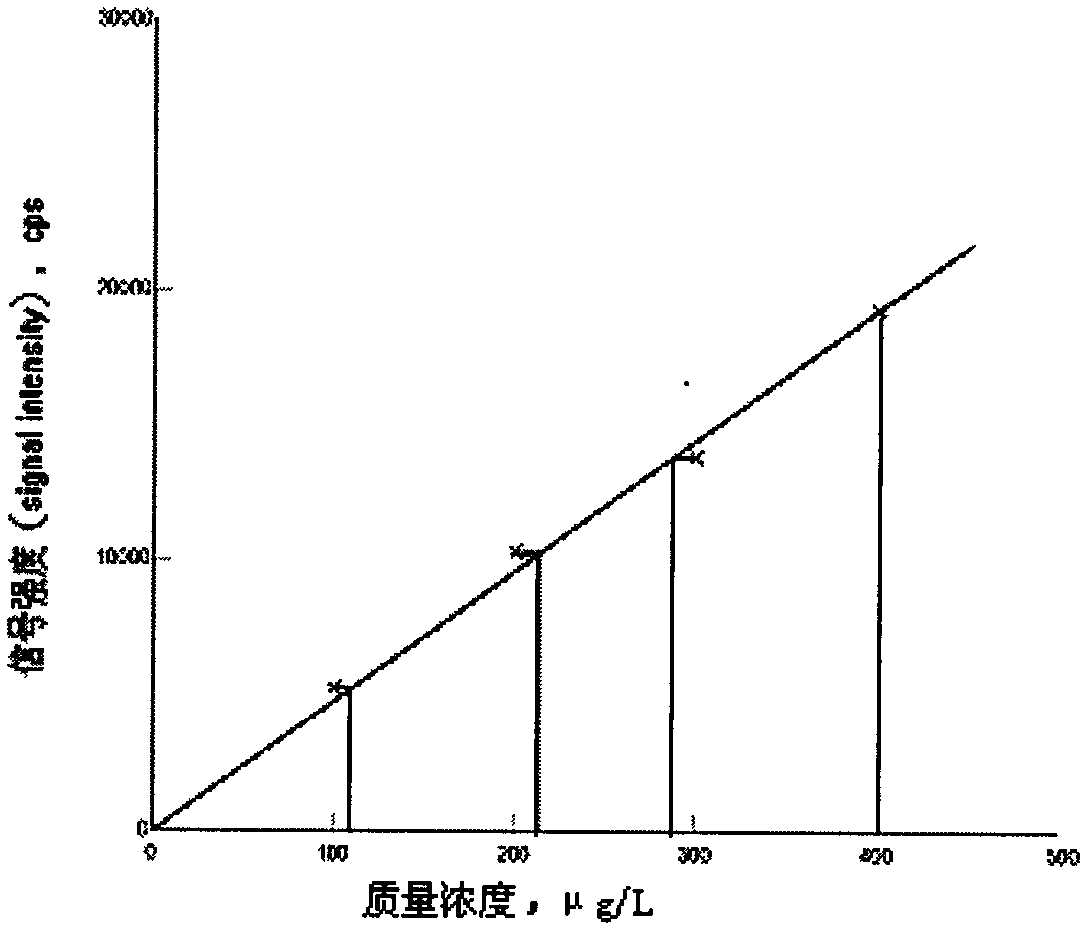

Image

Examples

Embodiment Construction

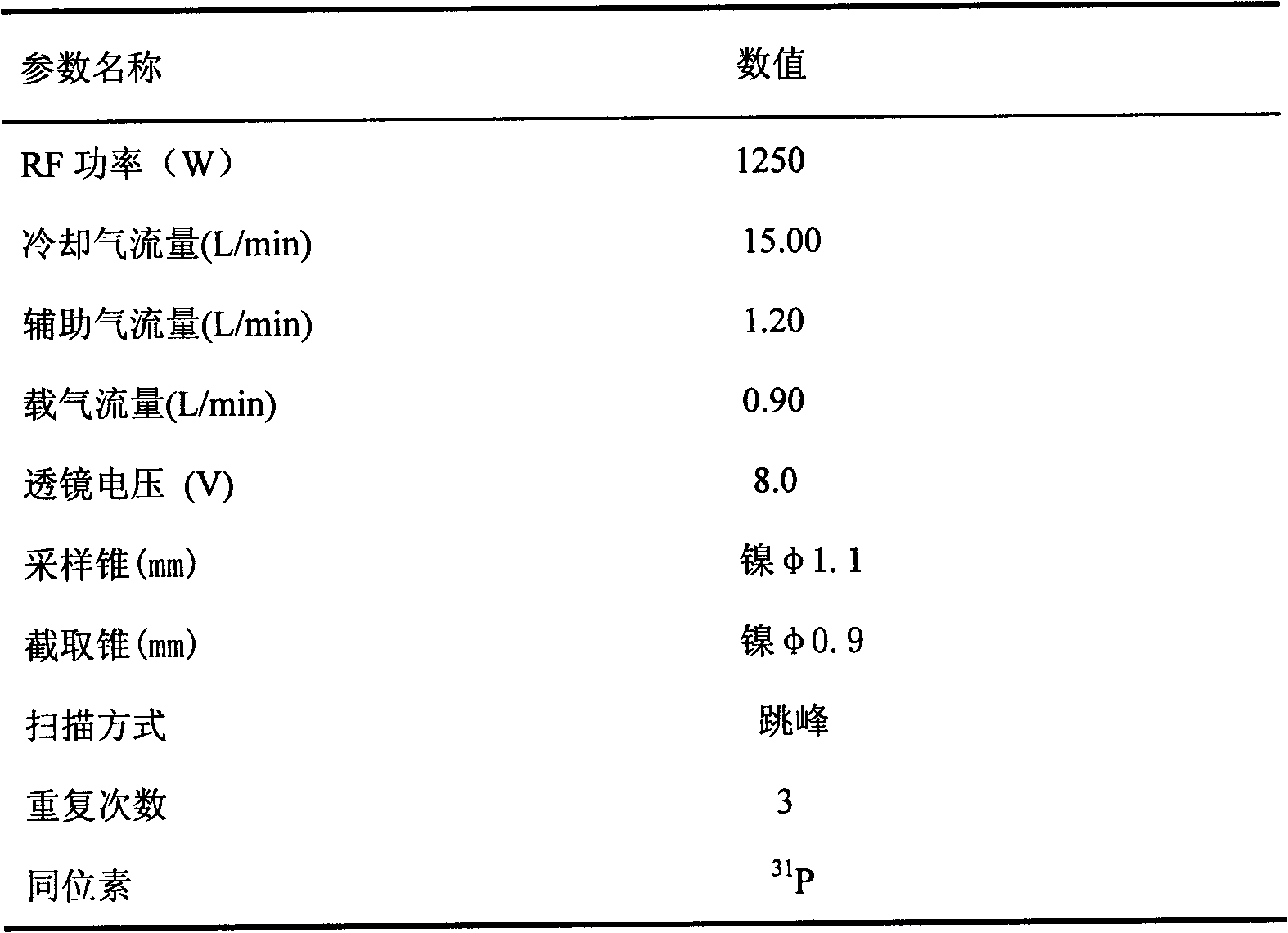

[0012] The technical solution involved in the present invention will be further described below in conjunction with specific examples, but it is not intended to limit the content of the invention.

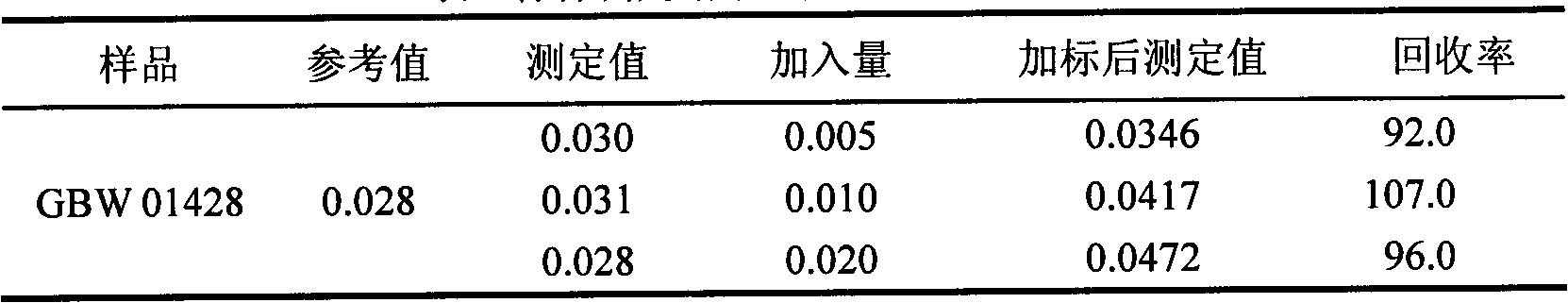

[0013] Taking the determination of phosphorus content in the national standard sample GBW 01428 ferrotungsten as an example, the technical scheme involved in the invention is described in detail.

[0014] a Sample treatment: Weigh 0.1000g sample into a polytetrafluoroethylene beaker, add 5mL high-purity concentrated nitric acid, 2mL high-purity concentrated hydrochloric acid, 1mL hydrofluoric acid, heat to dissolve at low temperature (200℃~250℃), and cool completely Finally, set the volume in a 100mL plastic volumetric flask as the solution to be tested.

[0015] b Preparation of blank solution: Add 5mL of high-purity concentrated nitric acid, 2mL of high-purity concentrated hydrochloric acid, and 1mL of hydrofluoric acid into a polytetrafluoroethylene beaker, heat to dissolve at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com