Method for purifying clavulanic acid from fermentation liquor

A technology of clavulanic acid and fermented liquid, applied in the direction of organic chemistry, can solve problems affecting the separation of clavulanate, follow-up operation of salt formation, long production process, low purity of clavulanic acid solution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

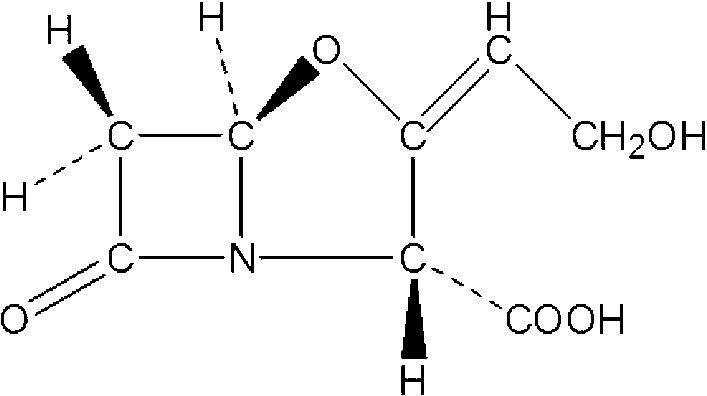

Image

Examples

Embodiment 1

[0016] Dilute the fermented broth containing crude clavulanic acid, mycelium, and other solid suspensions with water, adjust the pH value of the fermented broth to 4.8-5.5, and remove it through a tubular ultrafiltration membrane at a temperature of 4-10°C Suspended solids and some pigments are used to obtain permeate A. The selected tubular ultrafiltration membrane is polytetrafluoroethylene membrane, and the molecular cut-off is 10-200 kilodaltons. The flow rate of permeate A is controlled at 20-40L / m 2 .h; adjust the temperature of the permeate A to 4-10°C, and the pH value to be between 4.8 and 5.5, perform a first-level nanofiltration treatment on it through a first-level nanofiltration device, and remove the remaining pigment, protein and sugar to obtain the permeate B , the selected nanofiltration membrane is a polyamide membrane, the molecular cut-off is 200-1000 Daltons, and the flow rate of the permeate B is controlled to be 10-30L / m 2 .h; Finally, the permeate B i...

Embodiment 2

[0018] Dilute the fermented broth containing crude clavulanic acid, mycelia, and other solid suspensions with water, adjust the pH of the fermented broth to 5.5-6.2, and remove it through a tubular ultrafiltration membrane at a temperature of 10-15°C Suspended solids and some pigments are used to obtain permeate A. The selected tubular ultrafiltration membrane is polytetrafluoroethylene membrane, and the molecular cut-off is 10-200 kilodaltons. The flow rate of permeate A is controlled at 60-80L / m 2 .h; adjust the temperature of permeate A to 10-15°C, and perform primary nanofiltration treatment on it through primary nanofiltration equipment under the condition of pH 5.5-6.2, and remove the remaining pigment, protein and sugar to obtain permeate B , the selected nanofiltration membrane is a polyamide membrane, the molecular cut-off is 200-1000 Daltons, and the flow rate of the permeate B is controlled to be 20-30L / m 2 .h; Finally, the permeate B is subjected to secondary nan...

Embodiment 3

[0020] Dilute the fermented broth containing crude clavulanic acid, mycelia, and other solid suspensions with water, adjust the pH to 4.8-5.5, and remove the fermented broth through a tubular ultrafiltration membrane at a temperature of 4-10°C. Suspended solids and some pigments are used to obtain permeate A, the selected tubular ultrafiltration membrane is polytetrafluoroethylene membrane, the molecular cut-off is 10-200 kilodaltons, and the flow rate of permeate A is controlled to be 40-60L / m 2 .h; adjust the temperature of permeate A to 4-10°C, control the pH value to 4.8-5.5, pass permeate A through primary nanofiltration equipment for primary nanofiltration treatment, remove remaining pigment, protein and sugar to obtain permeate B. The selected nanofiltration membrane is a polyamide membrane, the molecular cut-off is 200-1000 Daltons, and the flow rate of the permeate B is controlled to be 20-30L / m 2 .h; Finally, the permeate B is subjected to secondary nanofiltration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com