A method for purifying clavulanic acid from fermentation broth

A technology of clavulanic acid and fermentation broth, applied in the direction of organic chemistry, etc., can solve the problems of emulsification, low purity of clavulanic acid solution, slow concentration rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

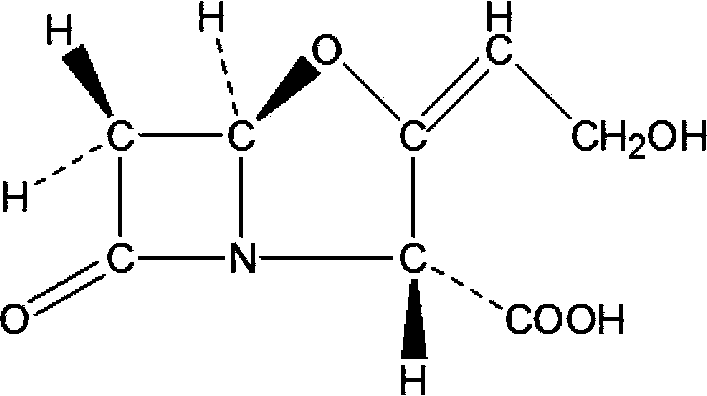

Image

Examples

Embodiment 1

[0016] Dilute the fermented broth containing crude clavulanic acid, mycelium, and other solid suspensions with water, adjust the pH value of the fermented broth to 4.8-5.5, and remove it through a tubular ultrafiltration membrane at a temperature of 4-10°C Suspended solids and some pigments are used to obtain permeate A. The selected tubular ultrafiltration membrane is polytetrafluoroethylene membrane, and the molecular cut-off is 10-200 kilodaltons. The flow rate of permeate A is controlled at 20-40L / m 2 .h; adjust the temperature of the permeate A to 4-10°C, and the pH value to be between 4.8 and 5.5, perform a first-level nanofiltration treatment on it through a first-level nanofiltration device, and remove the remaining pigment, protein and sugar to obtain the permeate B , the selected nanofiltration membrane is a polyamide membrane, the molecular cut-off is 200-1000 Daltons, and the flow rate of the permeate B is controlled to be 10-30L / m 2 .h; Finally, the permeate B i...

Embodiment 2

[0018] Dilute the fermented broth containing crude clavulanic acid, mycelia, and other solid suspensions with water, adjust the pH of the fermented broth to 5.5-6.2, and remove it through a tubular ultrafiltration membrane at a temperature of 10-15°C Suspended solids and some pigments are used to obtain permeate A. The selected tubular ultrafiltration membrane is polytetrafluoroethylene membrane, and the molecular cut-off is 10-200 kilodaltons. The flow rate of permeate A is controlled at 60-80L / m 2 .h; adjust the temperature of permeate A to 10-15°C, and perform primary nanofiltration treatment on it through primary nanofiltration equipment under the condition of pH 5.5-6.2, and remove the remaining pigment, protein and sugar to obtain permeate B , the selected nanofiltration membrane is a polyamide membrane, the molecular cut-off is 200-1000 Daltons, and the flow rate of the permeate B is controlled to be 20-30L / m 2 .h; Finally, the permeate B is subjected to secondary nan...

Embodiment 3

[0020] Dilute the fermented broth containing crude clavulanic acid, mycelia, and other solid suspensions with water, adjust the pH to 4.8-5.5, and remove the fermented broth through a tubular ultrafiltration membrane at a temperature of 4-10°C. Suspended solids and some pigments are used to obtain permeate A, the selected tubular ultrafiltration membrane is polytetrafluoroethylene membrane, the molecular cut-off is 10-200 kilodaltons, and the flow rate of permeate A is controlled to be 40-60L / m 2 .h; adjust the temperature of permeate A to 4-10°C, control the pH value to 4.8-5.5, pass permeate A through primary nanofiltration equipment for primary nanofiltration treatment, remove remaining pigment, protein and sugar to obtain permeate B. The selected nanofiltration membrane is a polyamide membrane, the molecular cut-off is 200-1000 Daltons, and the flow rate of the permeate B is controlled to be 20-30L / m 2 .h; Finally, the permeate B is subjected to secondary nanofiltration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com