Magnesium alloy surface phosphorus-free chromium-free conversion coating and application method thereof

A chrome-free conversion and magnesium alloy technology, applied in the field of magnesium alloy surface treatment, phosphorus-free chromium-free conversion film-forming liquid on the surface of magnesium alloy, can solve problems such as unstable process operation, complicated treatment process, general corrosion resistance, etc., to achieve Overcoming poor corrosion resistance, stable process operation, and superior corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The AZ31B magnesium alloy pretreated by degreasing, degreasing and pickling activation is placed in an ammonium metavanadate 2.0×10 -3 mol / L, sodium fluorosilicate 8.0×10 -4 mol / L, cerium nitrate 9.0×10 -3 mol / L, calcium chloride 1.0×10 -2 The mol / L composition of the magnesium alloy with a pH of 2.5 and a temperature of 40°C is converted into a film solution without phosphorus and chromium on the surface of the magnesium alloy, reacted for 30 minutes, washed with water and dried, that is, a conversion film is formed on the surface of the AZ31B magnesium alloy. The conversion film prepared in this example has a uniform color and does not corrode in a 76-hour neutral salt spray test.

Embodiment 2

[0050] Put the AZ31B magnesium alloy pretreated by degreasing, degreasing and pickling activation in sodium metavanadate 1.0×10 -3 mol / L, potassium fluorotitanate 6.0×10 -4 mol / L, lanthanum nitrate 1.0×10 -3 mol / L, magnesium nitrate 1.0×10 -3 The mol / L composition of the magnesium alloy with a pH of 2.2 and a temperature of 60°C is converted into a film solution without phosphorus and chromium on the surface of the magnesium alloy, reacted for 30 minutes, and washed with water to dry, that is, a conversion film is formed on the surface of the AZ31B magnesium alloy. The conversion film prepared in this example has a uniform color and does not corrode in a 56-hour neutral salt spray test.

Embodiment 3

[0052] Put the AZ31B magnesium alloy pretreated by degreasing, degreasing and pickling activation into ammonium metavanadate 1.0×10 -3 mol / L, ammonium fluorozirconate 4.0×10 -4 mol / L, cerium nitrate 9.0×10 -3 mol / L, magnesium chloride 1.0×10 -2 The mol / L composition of the magnesium alloy with a pH of 2.7 and a temperature of 50°C is converted into a film solution without phosphorus and chromium on the surface of the magnesium alloy, reacted for 20 minutes, washed with water and dried, that is, a conversion film is formed on the surface of the AZ31B magnesium alloy. The conversion film prepared in this example has a uniform color and does not corrode in a 48-hour neutral salt spray test.

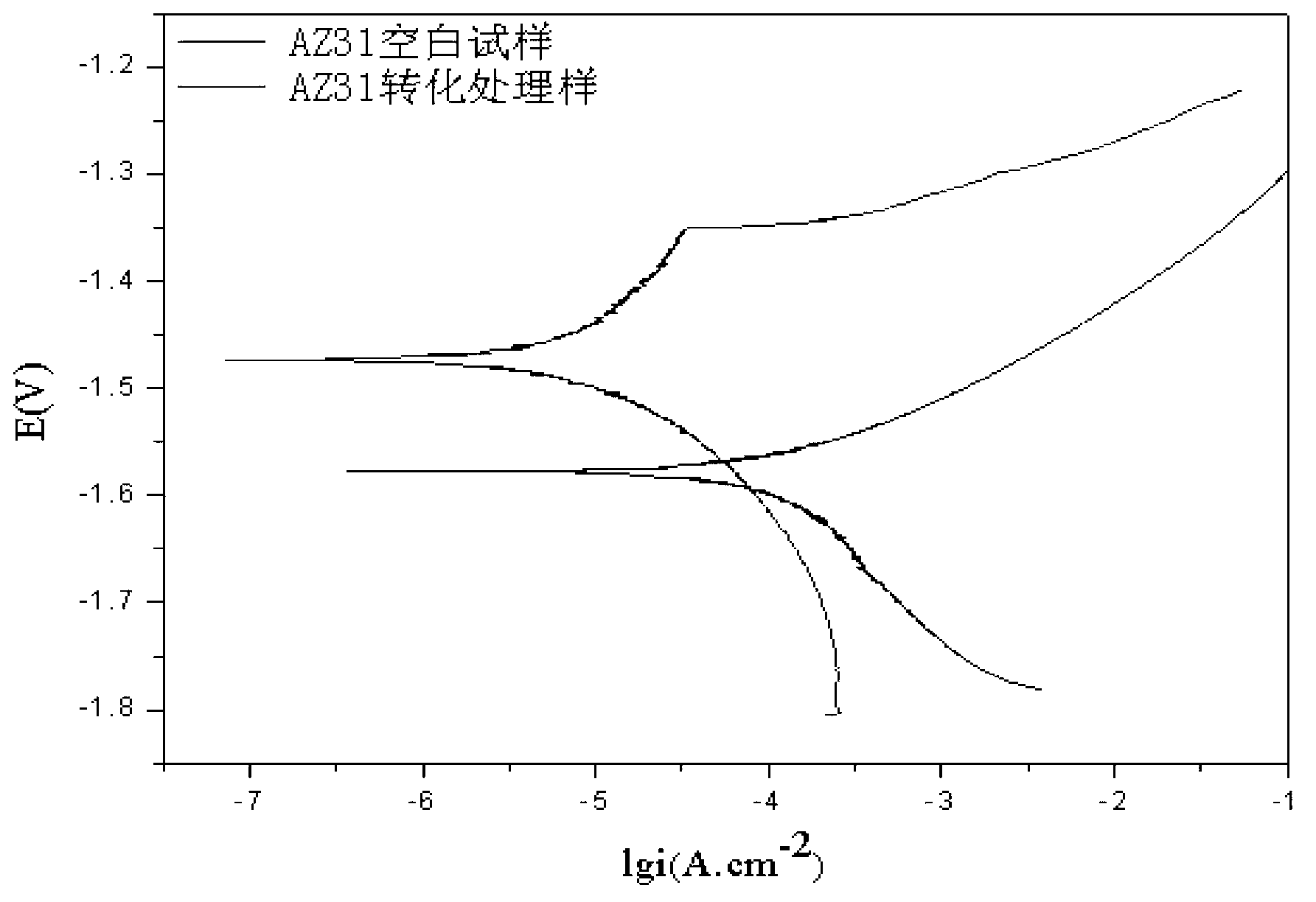

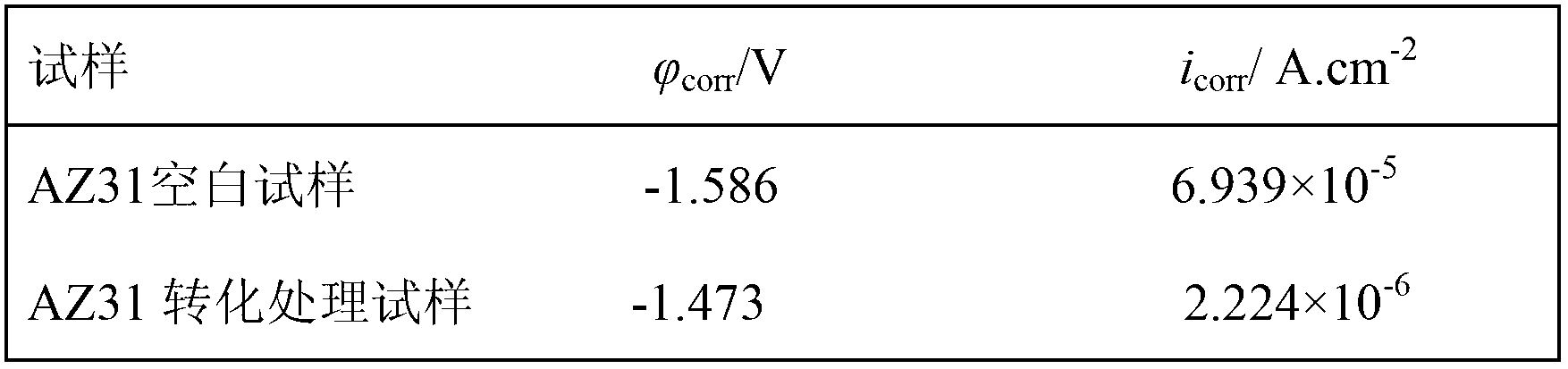

[0053] From figure 1 It can be seen from Table 2 that the corrosion potential of the conversion coating is positively shifted by 113 mV relative to the blank sample, and the corrosion current density is reduced by about 31 times. After the conversion treatment, the corrosion potential of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com