Low-temperature preparation method of TiO2-based organic/inorganic compound photocatalysis flexible film

A flexible film and inorganic composite technology, applied in the direction of coating, etc., can solve the problems of limited application, and achieve the effects of low temperature, excellent photocatalytic performance and good coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A TiO-based 2 The low-temperature preparation method of the organic / inorganic composite photocatalytic flexible film comprises the following steps:

[0037] 1) Preparation of titanium peroxide solution:

[0038] Take 100ml of TiCl with a concentration of 0.2mol / L 4 Aqueous solution, adjust TiCl with a mass concentration of 5% ammonia water 4 The pH of the aqueous solution is 9, and white orthotitanic acid precipitates are obtained; wash with deionized water until there is no chloride ion in the system; disperse the orthotitanic acid precipitates in 100ml of hydrogen peroxide solution with a mass concentration of 30%, and wait until the precipitation is complete After dissolving, add 0.01g of ferric iron tetroxide as a catalyst, heat at 50°C for 2 hours, remove free oxygen in the system, and centrifuge to obtain a yellow-brown transparent titanium peroxide solution;

[0039] 2) Mixing of polymer emulsion and titanium peroxide solution:

[0040] A certain amount of po...

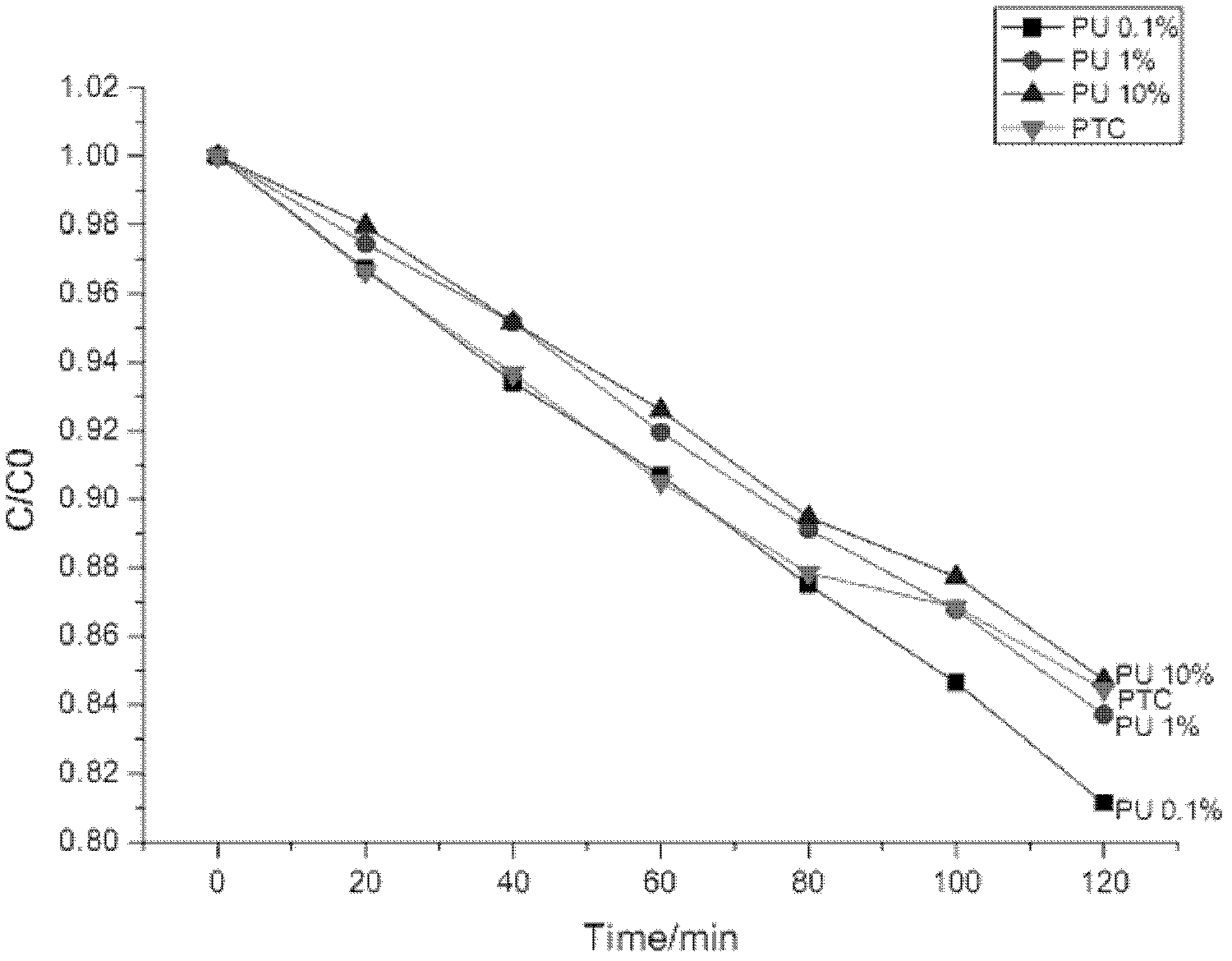

Embodiment 2

[0046] Repeat Example 1, the only difference is that the polyurethane in the composite material emulsion accounts for 1% by mass of the total solids.

Embodiment 3

[0048] Repeat Example 1, the only difference is that polyurethane accounts for 10% of the total solid mass percent in the composite material emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com