Heat-resistant engineered yeast strains for high-temperature high-efficiency xylose fermentation and application of heat-resistant engineered yeast strains

A technology of yeast strains and heat-resistant yeast, which is applied in application, fermentation, genetic engineering, etc., can solve the problem of low fermentation capacity and achieve the effect of increasing ethanol production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

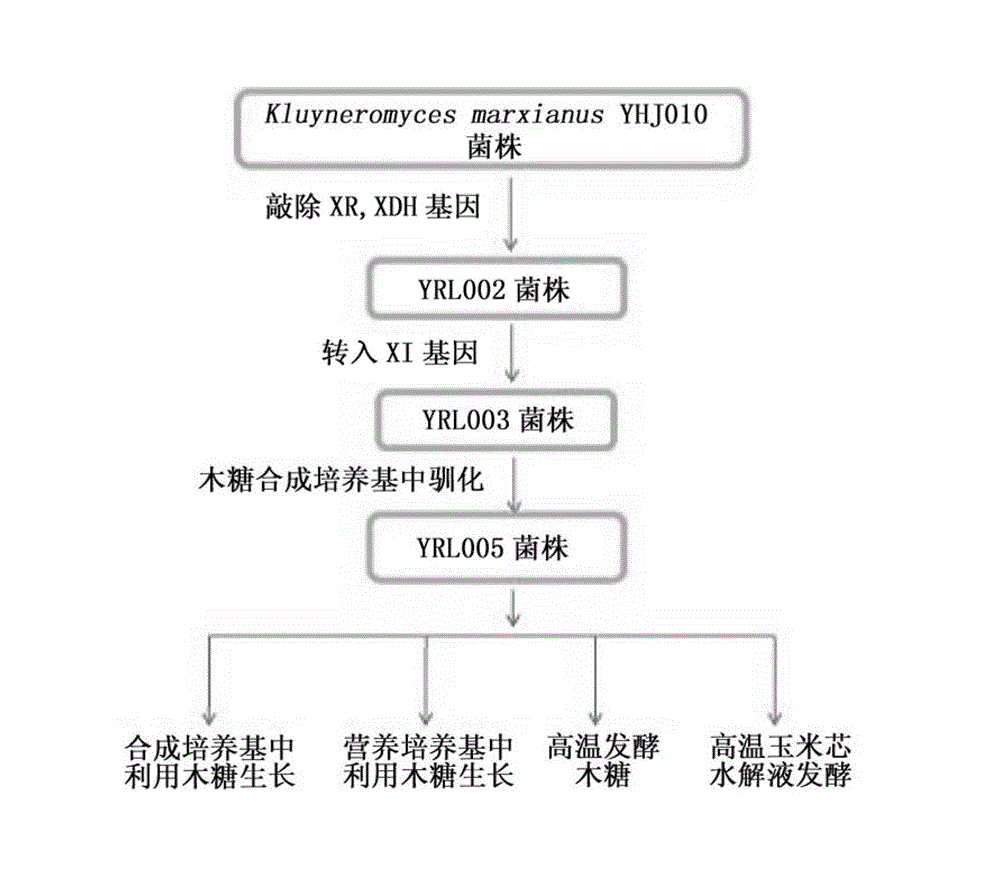

[0048] The preparation of embodiment 1 bacterial strain

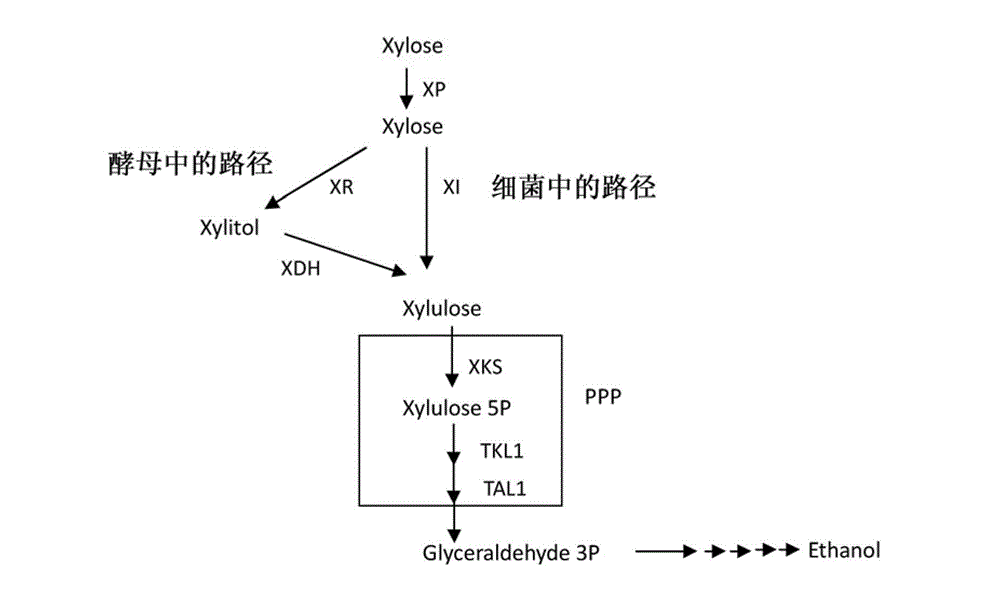

[0049] 1. Optimize the XI codon

[0050] The XI codon derived from the fungus Orpinomyces.sp (rumen fungus) is not necessarily the optimal codon in yeast, and if the original XI gene is used directly, the expression level may be low or even difficult to express. Under the premise of not changing the amino acid sequence, the codons in K. marxianus yeast were used for optimization, and primers for cloning were added at both ends. The obtained codon-optimized xylose isomerase gene sequence has a length of 1334 bp, as shown in SEQ ID NO:1.

[0051] 2. Synthesis of XI gene

[0052] The XI gene is divided into four fragments F1, F2, F3, and F4, whose lengths are F1 (356bp), F2 (354bp), F3 (354bp), and F4 (354bp). The sequences are recorded as SEQ ID NOs: 2-5. Each fragment is passed through the Tmprime tool ( http: / / prime.ibn.a-star.edu.sg / ) was cut into 11 oligonucleotides (including 6 positive strands (A strand) a...

Embodiment 2

[0205] Determination of xylose isomerase activity in the domesticated strain of embodiment 2

[0206] 1. Cultivate the acclimated strains YRL005, YHJ010 and YRL003 in 5ml liquid YPX medium for 48 hours.

[0207] 2. The bacterial cells were recovered by centrifugation at 1500 rpm at 4° C. for 10 min, and washed twice with 500 μl sterile water.

[0208] 3. Suspend the cells in 1ml buffer A (50mM Tris-HCl, 25mM NaCl, pH 8.0).

[0209] 4. The resulting suspension was disrupted by sonication. Vibra-Cell VC505 sonicator (Connecticut, USA) was used at 40% intensity for 10 min.

[0210] 5. Centrifuge at 15,000 rpm for 20 minutes at 4° C., and recover the supernatant as a crude enzyme solution.

[0211] 6. Configure 275 μl of xylose isomerase enzyme activity reaction system, including 100 μl of crude enzyme liquid and final concentration of 50 mM Na 3 PO 4 buffer (pH 8.0) and 40mM MgCl 2 .

[0212] 7. Add xylose with a final concentration of 20mM to start the enzyme activity r...

Embodiment 3

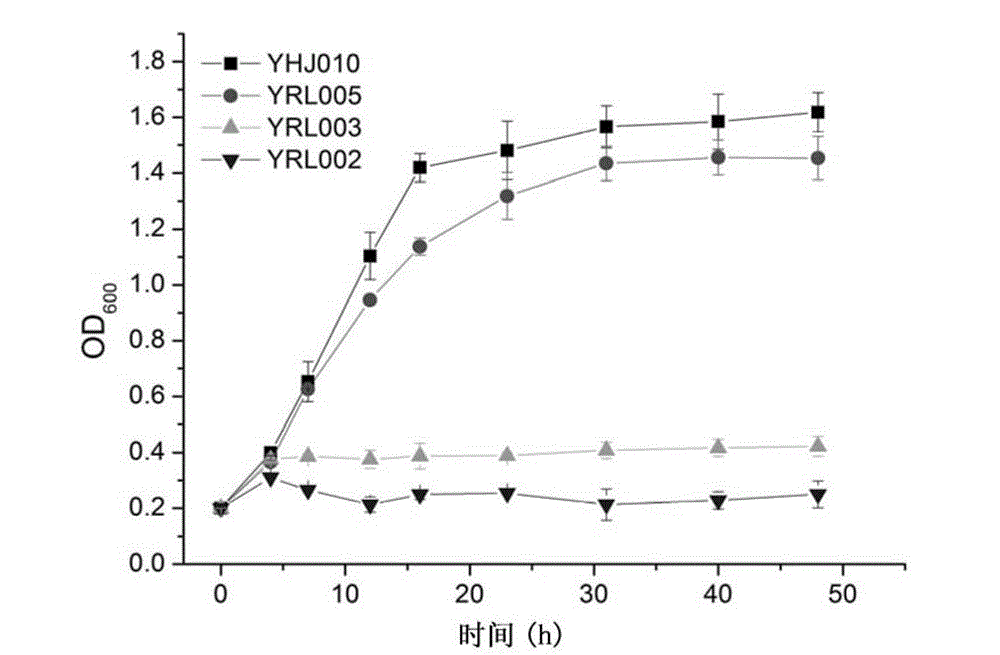

[0218] Embodiment 3 The growth situation of the domesticated bacterial strain under the synthetic medium

[0219] This example is used to understand the growth of the domesticated strain, its comparison with the wild-type strain NBRC1777 and its improvement over the strain YRL003 before domestication.

[0220] 1. Recover strains on YPD medium plates. Wild strain: NBRC1777. Domesticated strain: YRL005. Xylose metabolic pathway knockout strain: YRL002. Strain before acclimatization: YRL003. Cultured at 37°C for 1 day.

[0221] 2. Pick out single clones respectively, and connect them to 5ml liquid YPD medium. 37°C, 250rpm, overnight.

[0222] 3. Prepare 12 bottles of 50ml xylose synthesis medium and pack them in 250-ml Erlenmeyer flasks. Formula: 20g / l xylose, 6.7g / l YNB. Add amino acids respectively: leucine (30mg / ml), uracil (20mg / ml), tyrosine (20mg / ml). Sterilized and ready to use.

[0223] 4. Take an appropriate amount of overnight culture and transfer it to a ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com