Method for preparing Fe3O4 nanorods in gradient magnetic field

A gradient magnetic field and nanorod technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of reduced reaction rate and increased reaction time, and achieve improved reaction efficiency and fewer impurity particles , uniform length and diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

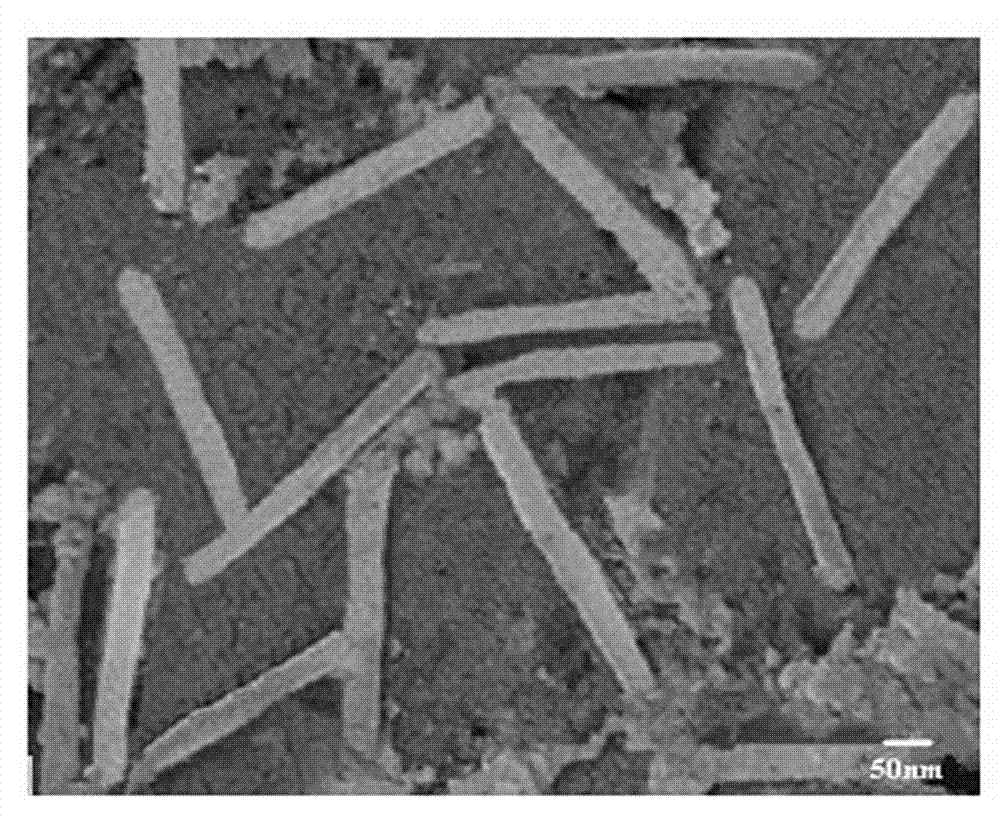

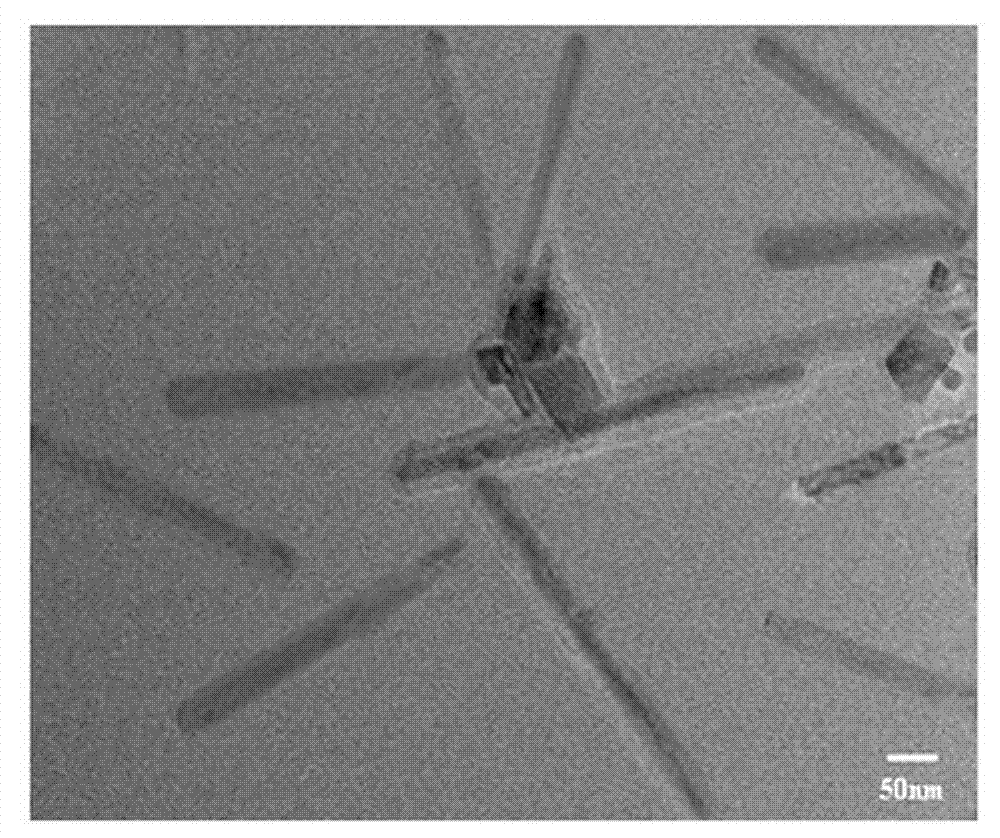

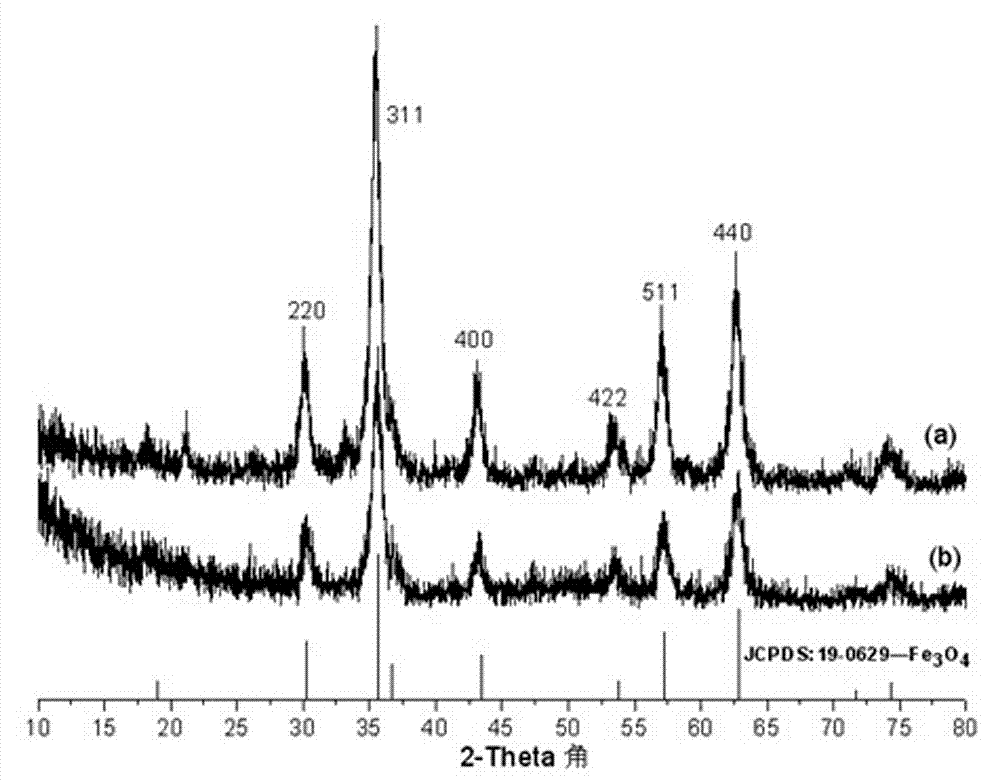

Embodiment 1

[0034] Prepare 1mol / L FeCl in volumetric flask 3 ·6H 2 O and FeSO 4 ·7H 2 O solution; mix the two solutions evenly with a volume ratio of 1.85:1, transfer them to a separatory funnel, and connect them to the ammonia gas collection bottle through a rubber stopper; place the gas collection bottle in an oil bath at 80°C, And place the oil bath between the magnetic poles, so that the magnetic field strength decreases from bottom to top in the vertical direction, and the product of magnetic induction and field strength gradient is 10T 2 / m; After heating to the constant temperature of ammonia gas, add the mixed solution dropwise. After the dropwise addition, keep the reaction for 50 minutes; cool to room temperature, wash the product with distilled water and ethanol respectively; dry it in a vacuum oven at 25°C for 6 hours and then measure the sample. Tests showed that the resulting Fe 3 o 4 The nanorods have a diameter of about 35nm, a length of about 330nm, and a saturation ...

Embodiment 2

[0036] Prepare 3mol / L of FeCl in the volumetric flask 3 ·6H 2 O and FeSO 4 ·7H 2 O solution; mix the two solutions evenly with a volume ratio of 1.9:1, transfer them to a separatory funnel, and connect them to the ammonia gas collection bottle through a rubber stopper; place the gas collection bottle in an oil bath at 85°C, And place the oil bath between the magnetic poles, so that the magnetic field strength decreases from bottom to top in the vertical direction, and the product of magnetic induction and field strength gradient is 40T 2 / m; After heating to the constant temperature of ammonia gas, add the mixed solution dropwise. After the dropwise addition, keep the reaction for 45 minutes, cool to room temperature, and wash the product with distilled water and ethanol respectively; dry it in a vacuum oven at 25°C for 6 hours and then measure the sample. Tests showed that the resulting Fe 3 o 4 The nanorod has a diameter of about 37nm, a length of about 340nm, and a sat...

Embodiment 3

[0038] Prepare 2mol / L of FeCl in the volumetric flask 3 ·6H 2 O and FeSO 4 ·7H 2 O solution; mix the two solutions evenly with a volume ratio of 1.85:1, transfer them to a separatory funnel, and connect them to the ammonia gas collection bottle through a rubber stopper; place the gas collection bottle in an oil bath at 90°C, Place the oil bath between the magnetic poles so that the magnetic field strength decreases from bottom to top in the vertical direction, and the product of magnetic induction and field strength gradient is 50T 2 / m; After heating to the constant temperature of ammonia gas, add the mixed solution dropwise. After the dropwise addition, keep the reaction for 50 minutes, cool to room temperature, and wash the product with distilled water and ethanol respectively; dry it in a vacuum oven at 25°C for 6 hours and then measure the sample. Tests showed that the resulting Fe 3 o 4 The nanorod has a diameter of about 39nm, a length of about 370nm, and a saturat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com