Electro-nickelling working solution for PET (polyethylene glycol terephthalate) substrate based FPC (flexible printed circuit) board

A technology of electroplating nickel and working fluid, which is applied in the field of electroplating nickel working fluid for FPC plates, can solve the problems of high scrap rate, copper foil falling off, difficulty in mass production, etc., and achieve the effect of improving yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

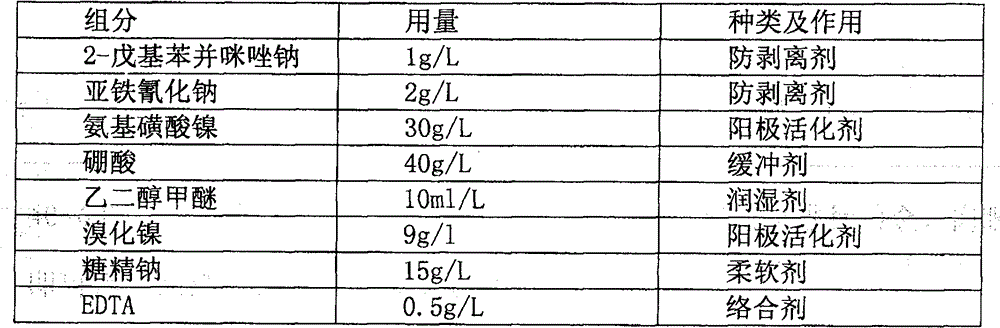

[0020] Select 2-pentylbenzimidazole sodium and sodium ferrocyanide to prepare nickel-plating working solution in a ratio of 1:2 by weight, and prepare nickel-plating working solution 1L with auxiliary softener, wetting agent, complexing agent and buffer , the specific dosage is shown in the table below.

[0021]

[0022] The electroplating nickel working solution prepared from the components in the above table treats the copper surface. The treatment process follows several steps such as degreasing→water washing→micro-etching→water washing→nickel plating→water washing→air drying→activation→gold plating. The nickel plating treatment temperature is 55 °C, and the treatment time was 5 minutes. Gold plating was performed after the treatment, and the PET base material and the copper surface did not peel off.

Embodiment 2

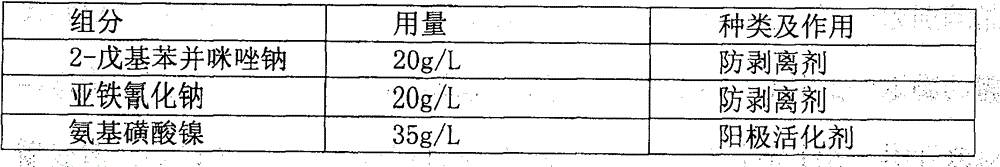

[0024] Select 2-pentylbenzimidazole sodium and sodium ferrocyanide to prepare nickel-plating working solution in a ratio of 1:1 by weight, and prepare nickel-plating working solution 1L with auxiliary softener, wetting agent, complexing agent and buffer , the specific dosage is shown in the table below.

[0025]

[0026]

[0027] The electroplating nickel working solution prepared from the components in the above table treats the copper surface. The treatment process follows several steps such as degreasing→water washing→micro-etching→water washing→nickel plating→water washing→air drying→activation→gold plating. The nickel plating treatment temperature is 55 °C, and the treatment time was 5 minutes. Gold plating was performed after the treatment, and the PET base material and the copper surface did not peel off.

Embodiment 3

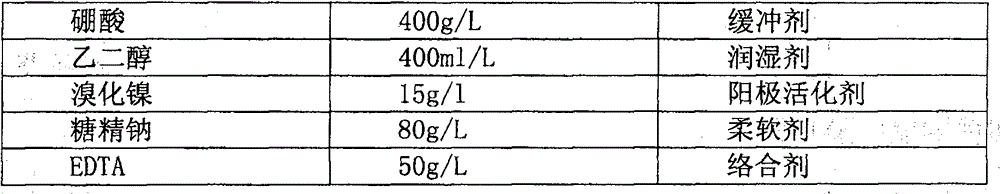

[0029] Select 2-pentylbenzimidazole sodium and sodium ferrocyanide to prepare nickel-plating working solution in a ratio of 1:1 by weight, and prepare nickel-plating working solution 1L with auxiliary softener, wetting agent, complexing agent and buffer , the specific dosage is shown in the table below.

[0030]

[0031] The electroplating nickel working solution prepared from the components in the above table treats the copper surface. The treatment process follows several steps such as degreasing→water washing→micro-etching→water washing→nickel plating→water washing→air drying→activation→gold plating. The nickel plating treatment temperature is 55 °C, and the treatment time was 5 minutes. Gold plating was performed after the treatment, and the PET base material and the copper surface did not peel off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com