Sunscreen external wall coating and preparation method thereof

A technology of exterior wall coatings and raw materials, applied in the field of decorative materials, can solve problems affecting the appearance of buildings, service life and product value, poor waterproof performance and light resistance, poor adhesion of exterior wall coatings, etc., to achieve paint film Excellent stability, good waterproof performance, complete and smooth paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

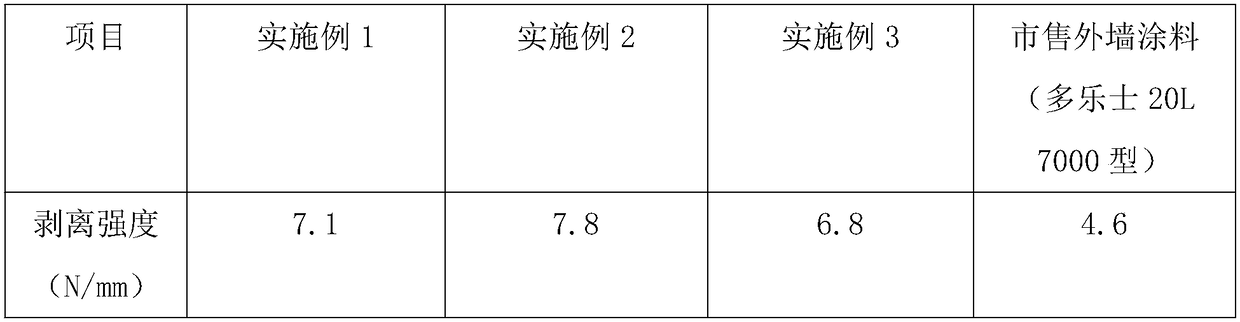

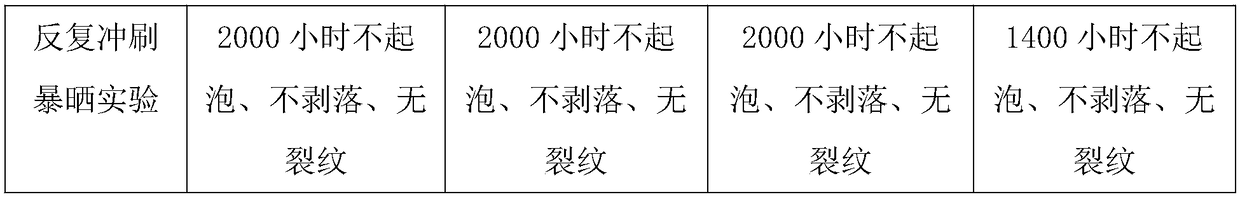

[0029] A sunscreen exterior wall coating, the following raw materials are weighed: 40kg of terpene resin, 10kg of polyurethane, 70kg of vinyl acetate-ethylene tertiary carbonate copolymer emulsion, 20kg of sodium bentonite, 3kg of hindered amine, and hydroxycyclohexanebenzophenone 1kg, dioctyl phthalate 1kg, dimethyl sulfoxide 1kg, adhesion aid 8kg, alkyl aryl polyether wetting agent 1kg, 2,2,4-trimethyl-1,3-pentane Diol diisobutyrate film-forming aid 1kg, 2,4,6-tris(2,4-dihydroxyphenyl)-1,3,5-triazine ultraviolet absorber 1kg and polyacrylic acid leveling agent 1kg ;

[0030] Preparation of bonding aids;

[0031] Step 1: Take the following raw materials: 4 kg of linseed gum, 1.5 kg of propyltrimethoxysilane, 1 kg of polyethylene oxide, 0.4 kg of sodium alginate and 1 kg of polyhexamethylene adipate;

[0032] Step 2: Heat linseed gum to 65°C, keep it warm for 30 minutes, add propyltrimethoxysilane and polyhexamethylene adipate while stirring, raise the temperature to 75°C, c...

Embodiment 2

[0038] A sunscreen exterior wall coating, the following raw materials are weighed: terpene resin 45kg, polyurethane 15kg, vinyl acetate-ethylene tertiary carbonate copolymer emulsion 75kg, sodium bentonite 25kg, hindered amine 4kg, hydroxycyclohexanebenzophenone 1.5kg, dioctyl phthalate 2kg, dimethyl sulfoxide 1.25kg, bonding aid 10kg, dioctyl sulfosuccinate sodium wetting agent 2kg, 2,2,4-trimethyl- 1,3-pentanediol diisobutyrate film-forming aid 3kg, 2(2-dihydroxybenzene-5-benzyl) benzotriazole ultraviolet absorber 2kg and carboxymethylcellulose leveling agent 3kg ;

[0039] Preparation of bonding aids;

[0040] Step 1: Take the following raw materials: 5 kg of linseed gum, 1.75 kg of propyltrimethoxysilane, 1.5 kg of polyethylene oxide, 0.5 kg of sodium alginate and 1.25 kg of polyethylene adipate;

[0041] Step 2: Heat linseed gum to 70°C, keep it warm for 35 minutes, add propyltrimethoxysilane and polyhexamethylene adipate while stirring, raise the temperature to 80°C, c...

Embodiment 3

[0047] A sunscreen exterior wall coating, the following raw materials are weighed: 50kg of terpene resin, 20kg of polyurethane, 80kg of vinyl acetate-ethylene tertiary carbonate copolymer emulsion, 30kg of sodium bentonite, 5kg of hindered amine, and hydroxycyclohexanebenzophenone 2kg, dioctyl phthalate 3kg, dimethyl sulfoxide 1.5kg, bonding aid 12kg, alkyl aryl polyether wetting agent 3kg, 2,2,4-trimethyl-1,3- Pentylene glycol diisobutyrate film-forming aid 5kg, 2,4 dihydroxybenzophenone ultraviolet absorber 3kg and polydimethylsiloxane leveling agent 5kg;

[0048] Preparation of bonding aids;

[0049] Step 1: Take the following raw materials: linseed gum 6kg, propyltrimethoxysilane 2kg, polyethylene oxide 2kg, sodium alginate 0.6kg and polyethylene adipate 1.5kg;

[0050] Step 2: Heat linseed gum to 75°C, keep it warm for 40 minutes, add propyltrimethoxysilane and polyhexamethylene adipate while stirring, raise the temperature to 85°C, continue stirring for 30 minutes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com