Production process for puffing lotus rhizome chips, and product thereof

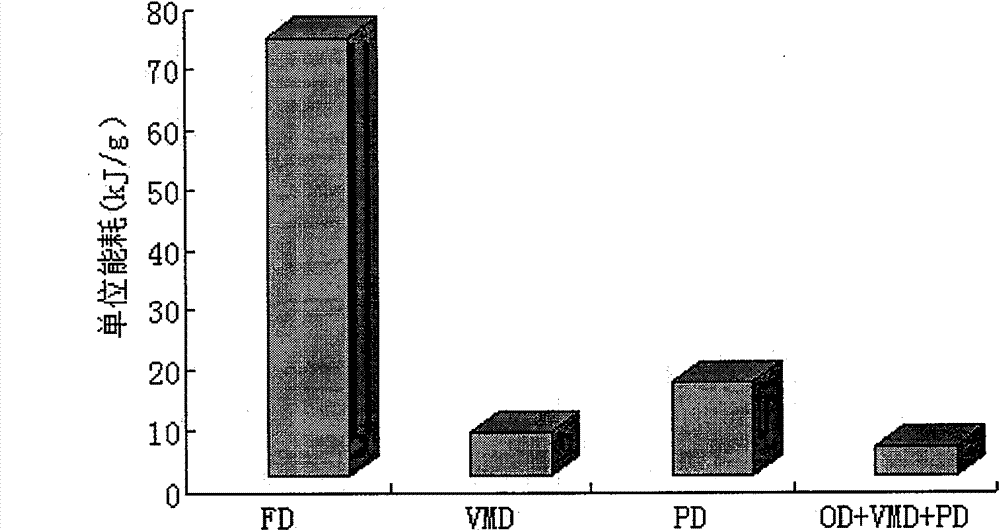

A technology of puffed lotus root and production technology, which is applied in food preparation, application, food science, etc., can solve the problems of loss of nutrients, poor quality, and adverse human health, and achieve the effect of improving production efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

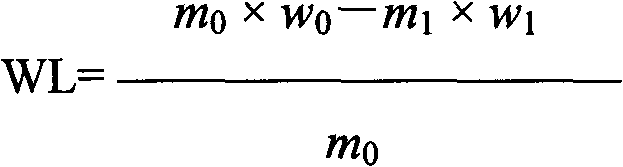

Method used

Image

Examples

Embodiment 1

[0026] 1. Cleaning, peeling, and slicing: choose white and well-developed lotus roots as raw materials, cut off the joints, and slice them with a SA-300D semi-automatic slicer (Guangzhou Minhong Food Machinery Co., Ltd.) after cleaning and peeling. The slice thickness is 6mm;

[0027] 2. Color protection: the lotus root slices are placed in the color protection solution rapidly, and the color protection solution is 1% (w / v) sodium chloride solution and 0.2% (w / v) citric acid solution according to the ratio of 1:1 (v / v). / v) Mixed configuration, the color protection time is 30min;

[0028] 3. Osmotic dehydration: put the lotus root slices in a 40% sucrose solution, the temperature of the solution is controlled at 50°C, and soak for 135 minutes for osmotic dehydration;

[0029] 4. Quick-freezing: the lotus root slices after infiltration and dehydration are input to the vibrating screen bed of the SL-I-500 fluidized bed quick-freezing machine (Laiyang Changyu Machinery Equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com