Microwave assisted preparation of hydroxyapatite hollow sphere

A hydroxyapatite, microwave-assisted technology, applied in phosphorus compounds, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of increasing process complexity, production cost, environmental pollution, etc., and achieve good application The effect of prospect, simple preparation process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

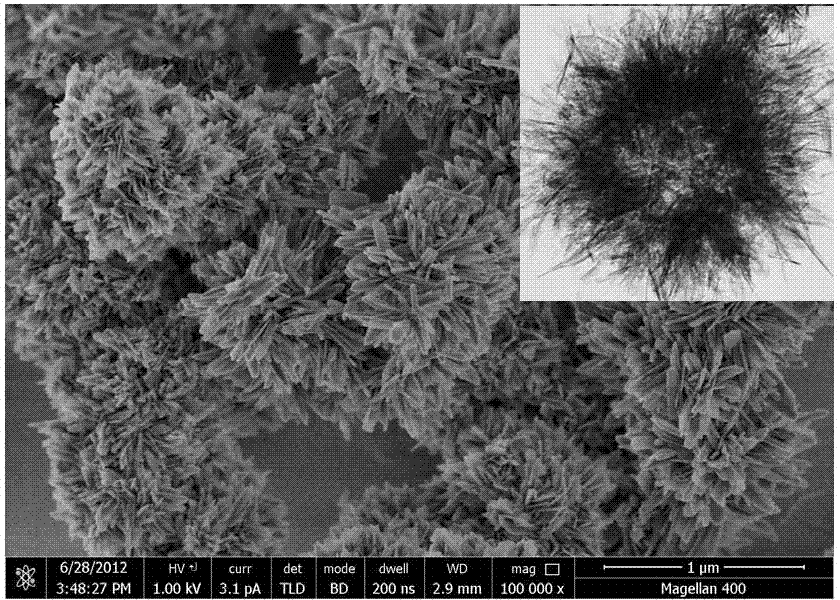

[0044] At room temperature, 0.111 g of CaCl 2 Dissolve in 30 ml of deionized water to form liquid A, and dissolve 0.196 g of creatine phosphate sodium salt in 10 ml of deionized water to form liquid B. After adjusting liquid A with 1 mol / L hydrochloric acid to make its pH equal to 5, add liquid B dropwise, and use magnetic stirring during this process to keep the pH at about 5. After the dropwise addition was completed, the mixed clear solution was transferred to a microwave reactor (capacity 60 ml) and reacted at 120 °C for 10 min. After the reaction system was naturally cooled to room temperature, the product was taken out and centrifuged. The separated product was washed three times with deionized water, once with absolute ethanol, and dried in air at 60°C to obtain image 3 The structure of the hydroxyapatite hollow sphere shown is that the hydroxyapatite hollow sphere is assembled by nanosheets, and the diameter of the hollow sphere is about 800 nanometers.

Embodiment 2

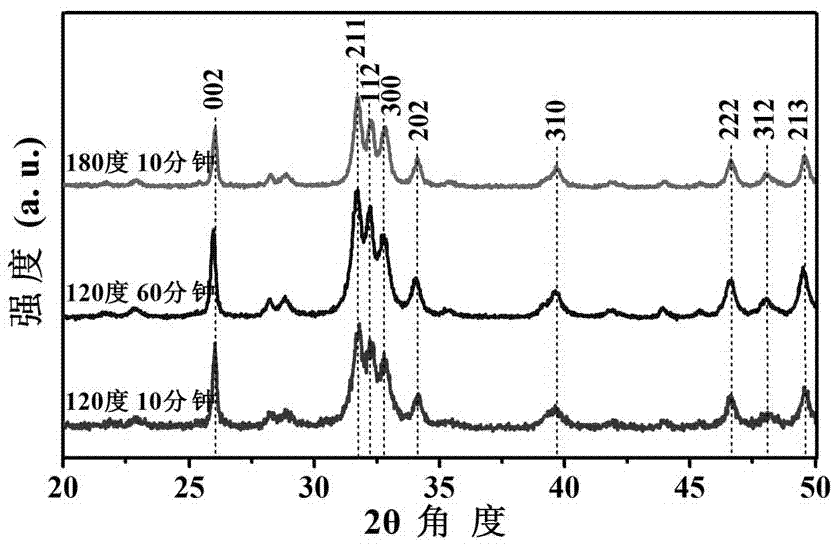

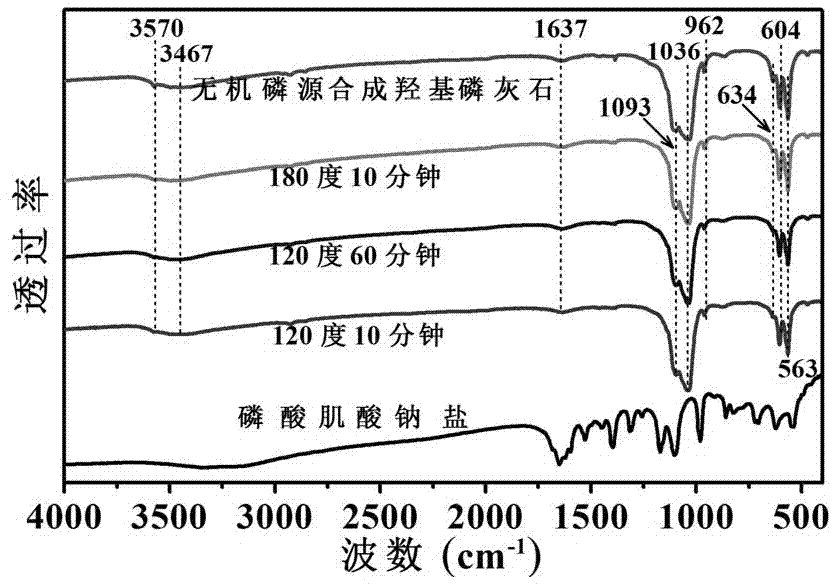

[0046] At room temperature, 0.111 g of CaCl 2 Dissolve in 30 ml of deionized water to form liquid A, and dissolve 0.196 g of creatine phosphate sodium salt in 10 ml of deionized water to form liquid B. After adjusting liquid A with 1 mol / L sodium hydroxide to make its pH equal to 10, add liquid B dropwise, and use magnetic stirring during this process to keep the pH at about 10. After the dropwise addition was completed, the mixed clear solution was transferred to a microwave reactor (capacity 60 ml) and reacted at 120 °C for 10 min. After the reaction system was naturally cooled to room temperature, the product was taken out and centrifuged. The separated product was washed three times with deionized water, once with absolute ethanol, and dried in air at 60°C to obtain Figure 4 The calcium phosphate hollow sphere structure shown is assembled from nanosheets, and the average diameter of the hollow spheres is 900 nanometers. see figure 1 It can be known that the calcium pho...

Embodiment 3

[0048] At room temperature, 0.022 g of CaCl 2 Dissolve in 30 ml of deionized water to form liquid A, and dissolve 0.039 g of creatine phosphate sodium salt in 10 ml of deionized water to form liquid B. After adjusting liquid A with 1 mol / L sodium hydroxide to make its pH equal to 10, add liquid B dropwise, and use magnetic stirring during this process to keep the pH at about 10. After the dropwise addition was completed, the mixed clear solution was transferred to a microwave reactor (capacity 60 ml) and reacted at 120 °C for 10 min. After the reaction system was naturally cooled to room temperature, the product was taken out and centrifuged. The separated product was washed three times with deionized water, once with absolute ethanol, and dried in air at 60°C to obtain Figure 5 The structure of the hydroxyapatite hollow sphere shown is that the hydroxyapatite hollow sphere is assembled by nanosheets, and the average diameter of the hollow sphere is 1 micron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com