Deep processing method for medium and low temperature coal tar

A technology for deep processing of low-temperature coal tar, which is applied in the field of coal chemical technology, can solve problems such as engine damage, reduce economic benefits, and environmental pollution, and achieve the effects of improving the properties of oil products, increasing service life, and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

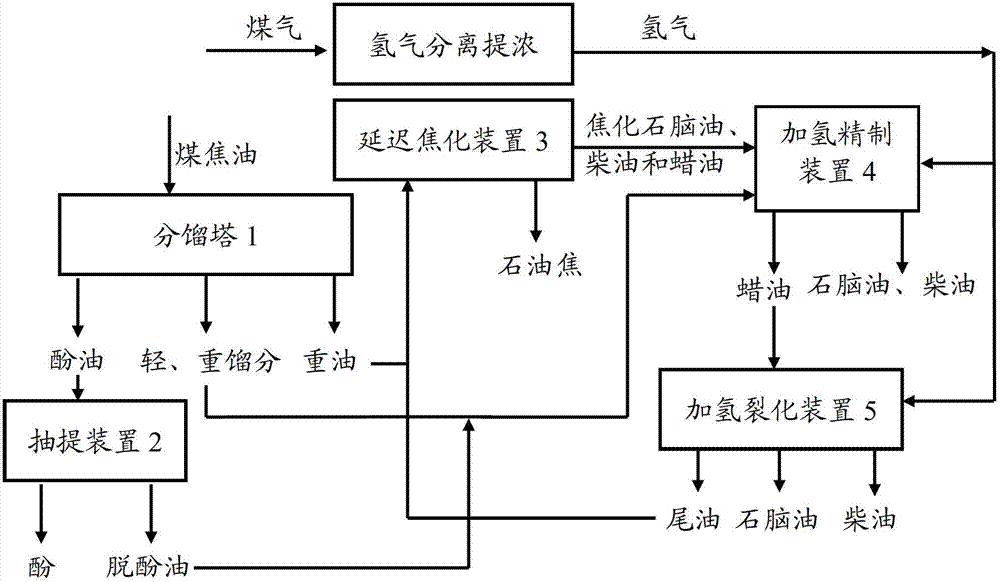

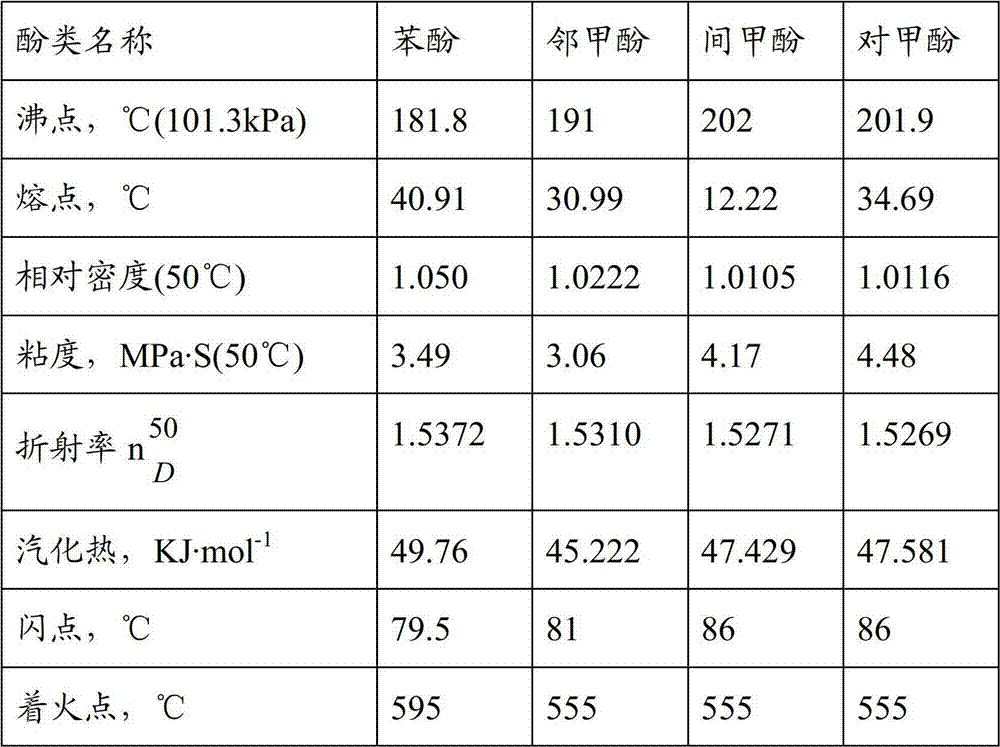

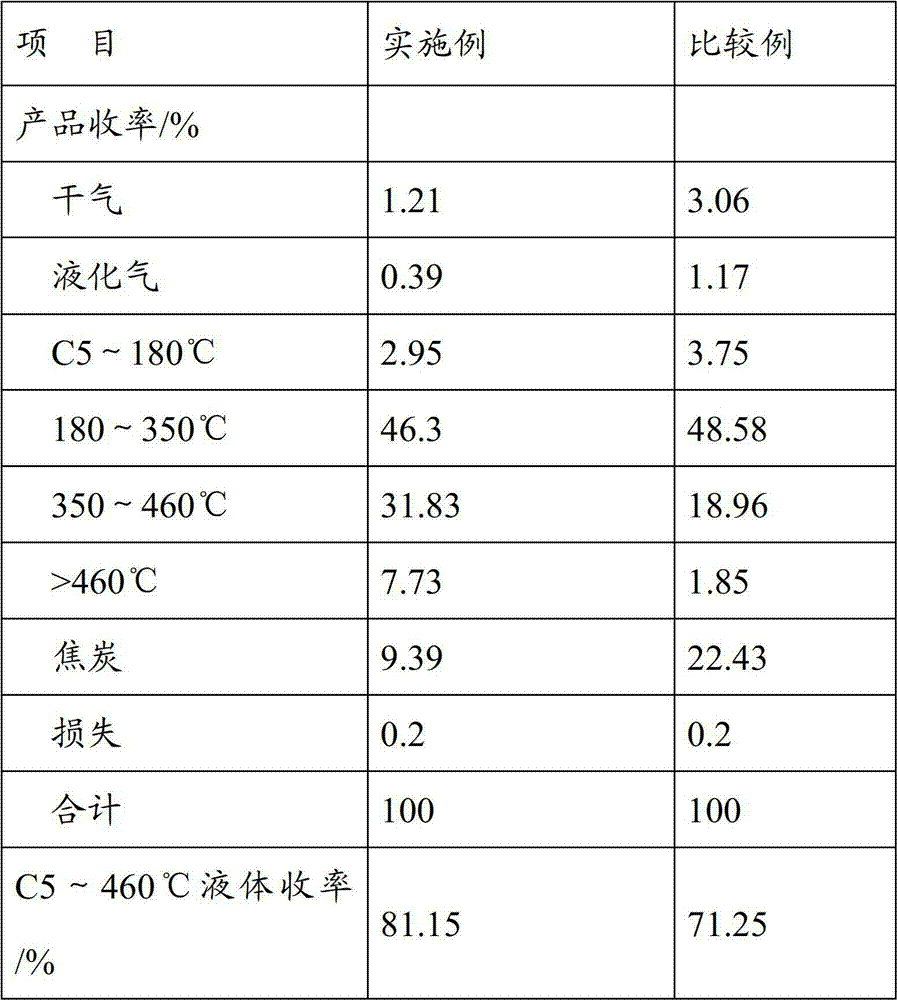

Embodiment 1

[0030] The low-temperature dry distillation coal tar from lignite in Shenmu County, whose properties are shown in Table 1, is sent to the pretreatment unit to remove mechanical impurities and water, and then enters the vacuum fractionation tower 1 to fractionate light distillate oil (overhead oil) and heavy distillate oil (side stream) , phenol oil (side line) and heavy oil, the phenol oil enters the phenol oil extraction unit 2 to separate phenolic products and dephenolized oil, and the heavy oil at the bottom of the tower is mixed with the unconverted tail oil of the hydrocracking section and enters the delayed coking unit 3 for thermal cracking reaction Coking dry gas, liquefied petroleum gas, coking naphtha, coking diesel oil, coking wax oil and petroleum coke are produced with a reaction temperature of 465°C and a reaction pressure of 0.23MPa. Among them, the coked naphtha, coked diesel oil, coked wax oil, light distillate oil from the fractionation tower 1, dephenolized o...

Embodiment 2

[0032] The low-temperature dry distillation coal tar from lignite in Shenmu County, whose properties are shown in Table 1, is sent to the pretreatment unit to remove mechanical impurities and water, and then enters the vacuum fractionation tower 1 to fractionate light distillate oil (overhead oil) and heavy distillate oil (side stream) , phenol oil (side line) and heavy oil, the phenol oil enters the phenol oil extraction unit 2 to separate phenolic products and dephenolized oil, and the heavy oil at the bottom of the tower is mixed with the unconverted tail oil of the hydrocracking section and enters the delayed coking unit 3 for thermal cracking reaction Coking dry gas, liquefied petroleum gas, coking naphtha, coking diesel oil, coking wax oil and petroleum coke are produced with a reaction temperature of 480°C and a reaction pressure of 0.17MPa. Among them, the coked naphtha, coked diesel oil, coked wax oil, light distillate oil from the fractionation tower 1, dephenolized o...

Embodiment 3

[0034] The low-temperature dry distillation coal tar from lignite in Shenmu County, whose properties are shown in Table 1, is sent to the pretreatment unit to remove mechanical impurities and water, and then enters the vacuum fractionation tower 1 to fractionate light distillate oil (overhead oil) and heavy distillate oil (side stream) , phenol oil (side line) and heavy oil, the phenol oil enters the phenol oil extraction unit 2 to separate phenolic products and dephenolized oil, and the heavy oil at the bottom of the tower is mixed with the unconverted tail oil of the hydrocracking section and enters the delayed coking unit 3 for thermal cracking reaction Coking dry gas, liquefied petroleum gas, coking naphtha, coking diesel oil, coking wax oil and petroleum coke are produced with a reaction temperature of 500°C and a reaction pressure of 0.17MPa. Among them, the coked naphtha, coked diesel oil, coked wax oil, light distillate oil from the fractionation tower 1, dephenolized o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com