Biological preparation for spinning silk and refining and removing oil as well as preparation method and application of biological preparation

A biological preparation and refining technology, applied in textiles and papermaking, biochemical fiber treatment, fiber treatment, etc., can solve the problems of harsh workshop environment, pollution, unstable effect, etc., achieve excellent fiber structure, easy control of conditions, and improve degreasing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

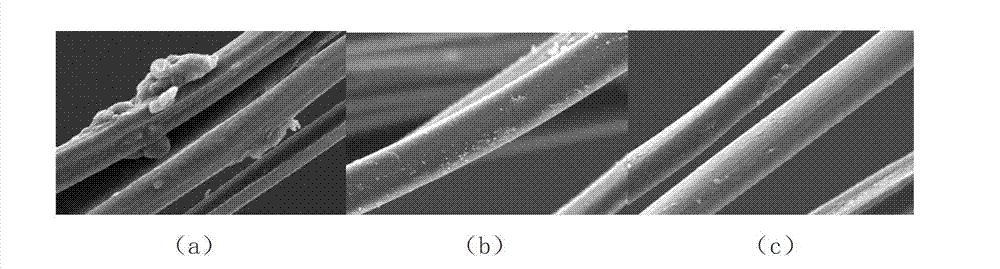

Image

Examples

Embodiment 1

[0028] In the present embodiment, the preparation method of the biological agent for degreasing by silk spinning comprises the following steps:

[0029] 1. The strain was inoculated into a lysis broth liquid culture bottle, placed on a constant temperature shaker, and cultured at 37°C and 150 r / min for 12 hours to obtain a seed liquid.

[0030] 2. Inoculate the seed liquid in proportion to 6% (volume ratio) in 1.5% bean cake flour liquid medium, and cultivate it for 84 hours at 37°C. When the number of viable bacteria fermented by culture is greater than 1 billion / ml, the bacterial strain is obtained fermentation broth.

[0031] 3. Centrifuge the fermentation liquid of the strain at 5500r / min for 8 minutes, discard the supernatant, and collect the wet bacteria as the sludge; mix the sludge with the freeze-drying agent, and the composition and ratio of the freeze-drying agent is 10% trehalose , 8% sucrose, 1% L-cysteine, 1% sodium glutamate. After mixing evenly, freeze-dry us...

Embodiment 2

[0043] In the present embodiment, the preparation method of the biological agent for degreasing by silk spinning comprises the following steps:

[0044] 1. The strain was inoculated into a liquid culture bottle of lysis broth, cultured with shaking at 38°C for 16 hours, and the morphology and purity of the strain were checked. Inoculate 6% (volume ratio) of qualified seed liquid in a liquid medium containing 2% beef extract and 1% maltose, and ferment at 37°C for 96 hours to obtain strain fermentation liquid.

[0045] 3. Centrifuge the fermentation broth of the strain at 8000r / min for 5 minutes, discard the supernatant, and collect the wet bacteria as the sludge; mix the sludge with sterilized anhydrous calcium chloride at a ratio of 1:1 and stir evenly , adding 5% sucrose, drying to a water content of 7%, and grinding into dry powder to obtain strain powder. After mixing evenly, it is freeze-dried in a vacuum freeze dryer at -5°C under aseptic conditions until the water cont...

Embodiment 3

[0055] The preparation conditions and process of this embodiment are basically the same as those of Example 1. Wherein, in this embodiment, the rotation speed of the shaker culture is 220r / min.

[0056] The biological preparation for silk spinning scouring and degreasing prepared in this example contains components and mass ratios as follows:

[0057] Strain powder 10 parts

[0058] The powder ratio of three strains of Bacillus cereus, Actinomyces A2016 and Pseudomonas fluorescens is 3:1:1

[0059] 50 parts corn stalk powder

[0060] 25 parts sawdust

[0061] Pseudomonas cepacia lipase 5 parts

[0062] 10 parts of UN-503 alkaline lipase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com